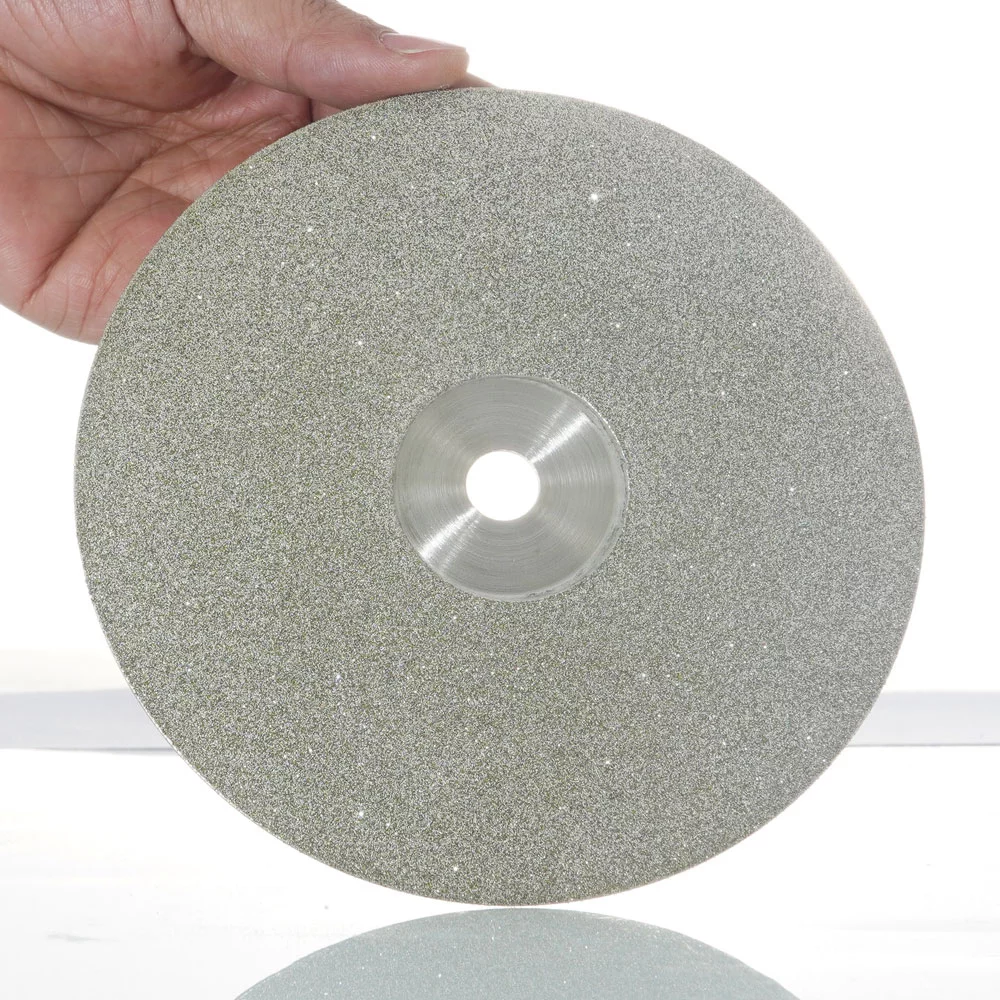

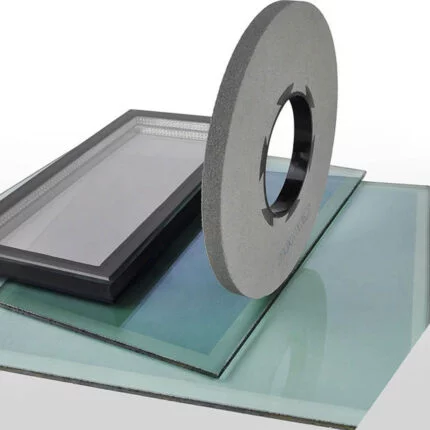

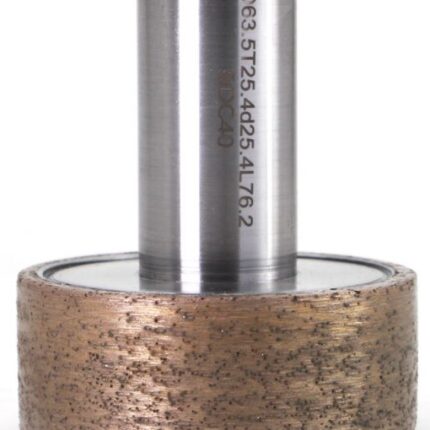

A lapidary can use a flat diamond lap to do rough and fine grinding on Sapphires and even for general lapidary grinding when precision is needed. Diamond lap discs can otherwise be called toppers, top plates, or faceting laps. As nickel electroplated, diamond lap discs use top-grade diamond powder onto 1mm-thick steel, which results in the highest quality lap that can be seen on the market.

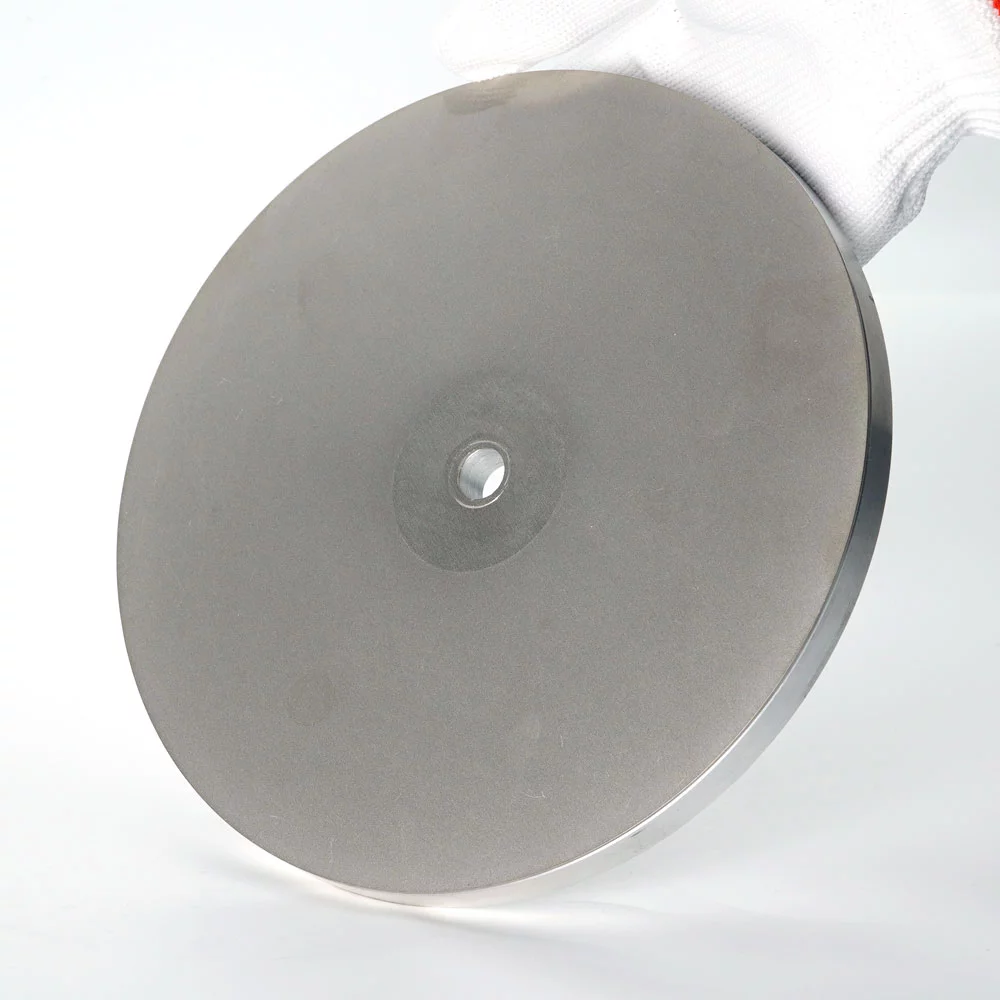

Flat diamond lap discs are designed with steel, which makes them have a long lifespan significantly. Besides, they are ideal for more heavy-duty grinding.

Diamond lap discs can be used on Slant Clabber lap machines and other flat lap machines that support a 1/2″ arbor. They come in 6” and 8″ lap diameter, which can be seen in a large variety of different grits.

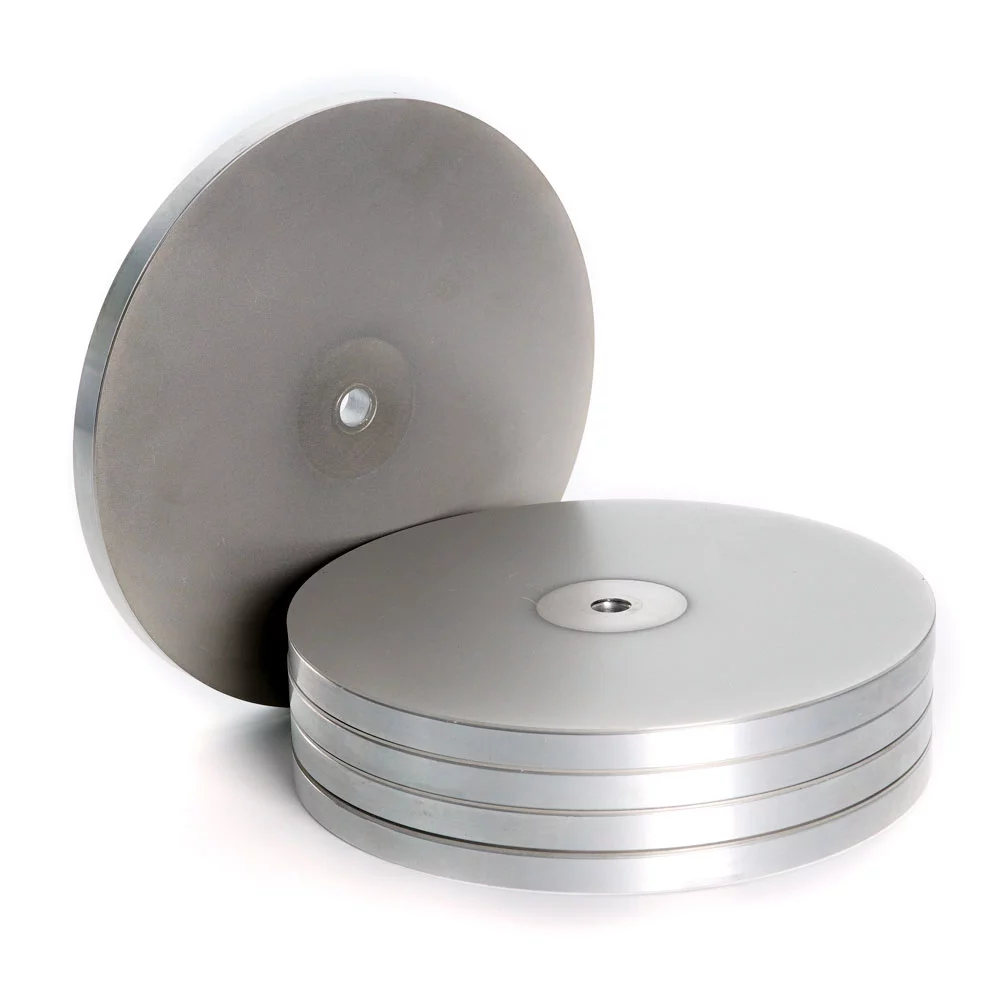

Diamond lap discs are available in two specific options. You can either choose to buy them with backing plates or not. When you get them with backing plates, they will feature pre-bound to an acrylic backing plate, which makes additional assembly unnecessary.

On the other side, when you get them without backing plates, they will feature a 3M pressure-sensitive and high-tack adhesive backing, which makes the application to backing plates easy. In addition, virtually every diamond lap disc made comes with 1/2″ arbor holes. It should also be noted that the maximum RPM is 4,000.

Uses

A flat diamond lap disc is preferred based on several reasons relating to use. They are perfect tools for the commercial cutter or any serious hobbyist for the following actions on Sapphires.

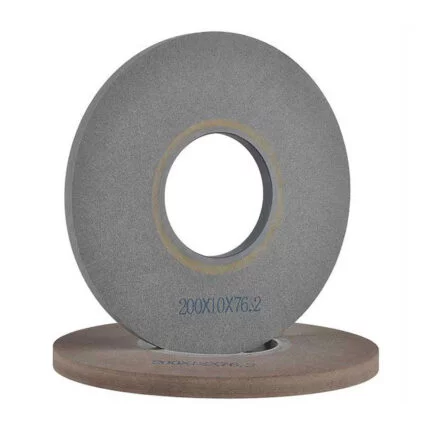

- Grinding and shaping: This is a process whereby diamond-impregnated wheels are used to shape gemstones to a desired rough form. This rough form is referred to as a preform.

- Lapping: lapping is very close to grinding and sanding, but it’s a process that involves one side of a vibrating or rotating flat disk called a lap. It’s used to make a flat surface on a stone which is known as faceting. Laps can be made of a copper-bronze alloy, cast iron, and steel.

- Faceting: This is a process of reducing fine rough into a scintillating finished gemstone.

- Cutting: This is a process that involves polishing rough gem materials into rounded or faceted forms for use. It’s a process referred to as lapidary or gem-cutting.

Specifications

Below are the specs of flat diamond lap disc featuring lap diameter, hole size, and thickness:

| Flat Diamond Lap Disc for Sapphire | |||

| Material | Lap Diameter | Hole size | Thickness |

| Diamond | 6″ and 8″ | 1/2″ (12.7mm) | 3/64″ (1.2mm) |

| The specification of polishing wheels for a lapidary gemstone is subject to change | |||

Features of Flat Diamond Lap Disc for Sapphire

There are numerous reasons flat diamond lap disc can be preferred to other similar products when working on a gemstone like sapphire. Some of these distinctive features include:

- Ideal tool for cutting, grinding, faceting, shaping, and lapping gemstones

- Perform both rough and fine grinding

- Offer general lapidary grinding when precision is needed

- Have a long lifespan and is perfect for more heavy-duty grinding

- Seen in standard 6″ and 8″ diameters with 1/2″ arbor holes and can be customized according to the customer’s desired dimensions.

Summary

Every gem cutter knows how important flat diamond lap discs are. Since they are great for grinding, shaping, lapping, faceting, and cutting, they can be considered great recommendations for any lapidarist. With them featuring suitable specifications and unique qualities, they are really worth going for.

More customized grinding wheels are available, contact us.

[wpforms id=”4612″]

Reviews

There are no reviews yet.