Types of Magnetic Materials

Magnetic materials can be divided into ferromagnetic, paramagnetic, and diamagnetic materials according to their magnetic properties. According to material characteristics, they can be divided into magnetic metals and non-magnetic metals.

The strong magnetism of ferromagnetic materials mainly comes from their microstructure with natural magnetization. Common ferromagnetic materials include metal ferromagnetic materials, including metals such as iron, nickel, cobalt, and their alloys, as well as crystal-like ferromagnetic materials, such as ferrites, barium ferrites, and manganese-zinc ferrites.

Paramagnetic materials can be magnetized in an external magnetic field, but their magnetization is very small, much weaker than ferromagnetic materials. Paramagnetic materials mainly include oxides, precious metals, rare earth metals, etc.

Diamagnetic materials do not become magnetized in an external magnetic field, but instead have diamagnetic properties, such as copper, silver, gold, aluminum, etc.

In addition, according to the application field and characteristic requirements of magnetic materials, magnetic materials can also be divided into two categories: soft magnetic materials and hard magnetic materials. Soft magnetic materials can quickly magnetize and demagnetize under the action of an external magnetic field and are suitable for magnetic cores and magnetic rings in electromagnetic devices such as transformers and inductors. Hard magnetic materials have strong saturation magnetization and coercive force and are suitable for magnetic permanent magnets, electromagnetic suction cups, sensors, and measuring instruments.

Magnetic materials can also be divided into two categories: metal and non-metal.

Metal magnetic materials usually refer to magnetic materials made of iron, nickel, cobalt, and their alloys. Metal magnetic materials are divided into soft magnetic materials and hard magnetic materials. Soft magnetic materials have low coercive force and high permeability and are widely used in electromagnetic applications of electronic components, such as transformer cores and inductors. Hard magnetic materials have high coercive force and strong magnetism and are suitable for magnetic permanent magnet applications, such as magnets, motors, sensors, and measuring instruments.

Non-metallic magnetic materials usually refer to materials that exhibit magnetic properties by processing and modifying non-metallic raw materials, including ferrites, oxide magnets, melt magnets, superconducting magnets, polymer magnets, etc. These materials have great differences in preparation technology and physical properties, and their application fields are also different. Non-metallic magnetic materials have gradually become important materials in information technology, energy, environmental protection, and life sciences.

Is a magnet a magnetic material?

Yes, a magnet is one of the ferromagnetic materials and has strong magnetism. It is made of metals such as iron, nickel, and cobalt, and can generate a strong magnetic field after magnetization treatment. Due to its strong magnetism, magnets are often used to make magnetic devices such as motors, transformers, generators, and various magnetic devices such as door magnets and magnetic buckles.

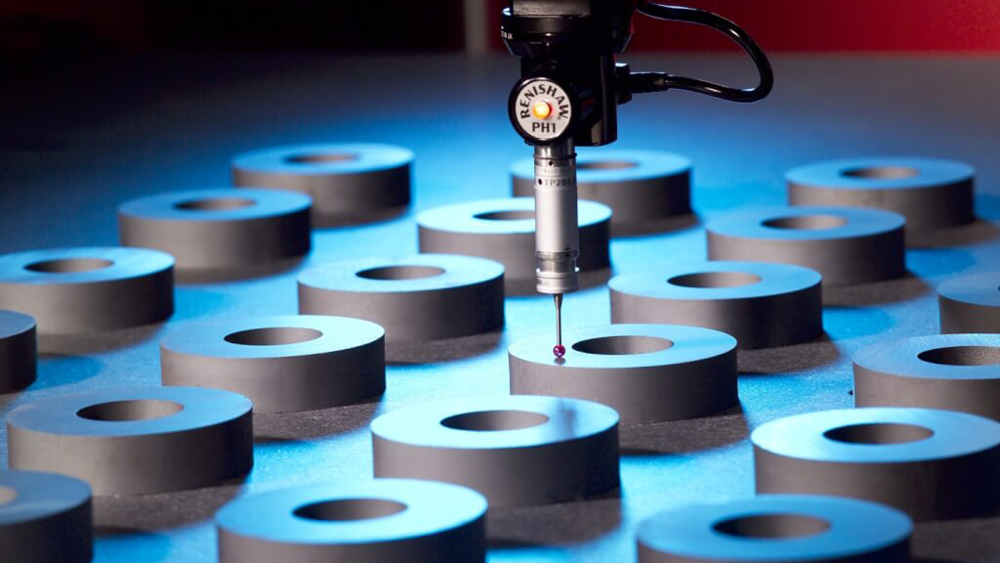

Selection of grinding wheels for metal and non-metal magnetic materials

There are huge differences in hardness and mechanical properties between metal and non-metal magnetic materials, so different types of grinding wheels need to be selected for processing and grinding.

For metal magnetic materials, it is recommended to use CBN (cubic boron nitride) grinding wheels for processing, because CBN grinding wheels have high hardness, wear resistance, and high-temperature resistance, and are suitable for processing many high-hardness metal materials. A special passivation coating is usually applied to the surface of the CBN grinding wheel to enhance its wear resistance and extend its service life.

Selection of grinding wheels for metal and non-metal magnetic materials

There are huge differences in hardness and mechanical properties between metal and non-metal magnetic materials, so different types of grinding wheels need to be selected for processing and grinding.

For metal magnetic materials, it is recommended to use CBN (cubic boron nitride) grinding wheels for processing, because CBN grinding wheels have high hardness, wear resistance, and high-temperature resistance, and are suitable for processing many high-hardness metal materials. A special passivation coating is usually applied to the surface of the CBN grinding wheel to enhance its wear resistance and extend its service life.

For some non-metal magnetic materials, such as magnetic ceramics and magnetic glass, conventional grinding wheels are prone to wear or distortion due to high hardness and fragility. Therefore, it is recommended to use diamond grinding wheels or CNC cutting tools for processing. These tools have high hardness, wear resistance, and size stability, and can withstand extremely high grinding forces and high temperatures.

In summary, different types of magnetic materials require different types of grinding wheels for grinding and processing to ensure processing quality and efficiency.