Today Mrbrianzhao is gonna recommend a set of diamond grinding wheels which are special used for lapidary grinding and polishing, Electroplated diamond grinding wheel with steel body or plastic body can be used for gemstone grinding, and soft flexible grinding wheels are suitable for polishing.

Electroplated diamond grinding wheel with steel or plastic body

Electroplated diamond grinding wheel with rough grit and fine grit from 60# ~ 3000#, rough grit can grind lapidary fast and fine grit can make stones have much better surfacing result.

Soft flexible diamond Polishing wheel for lapidary finishing

Soft flexible diamond sanding Polishing wheel has a much finer grit, after rough and fine grinding, then use this type of polishing wheel for superfinishing lapidary and gemstones.

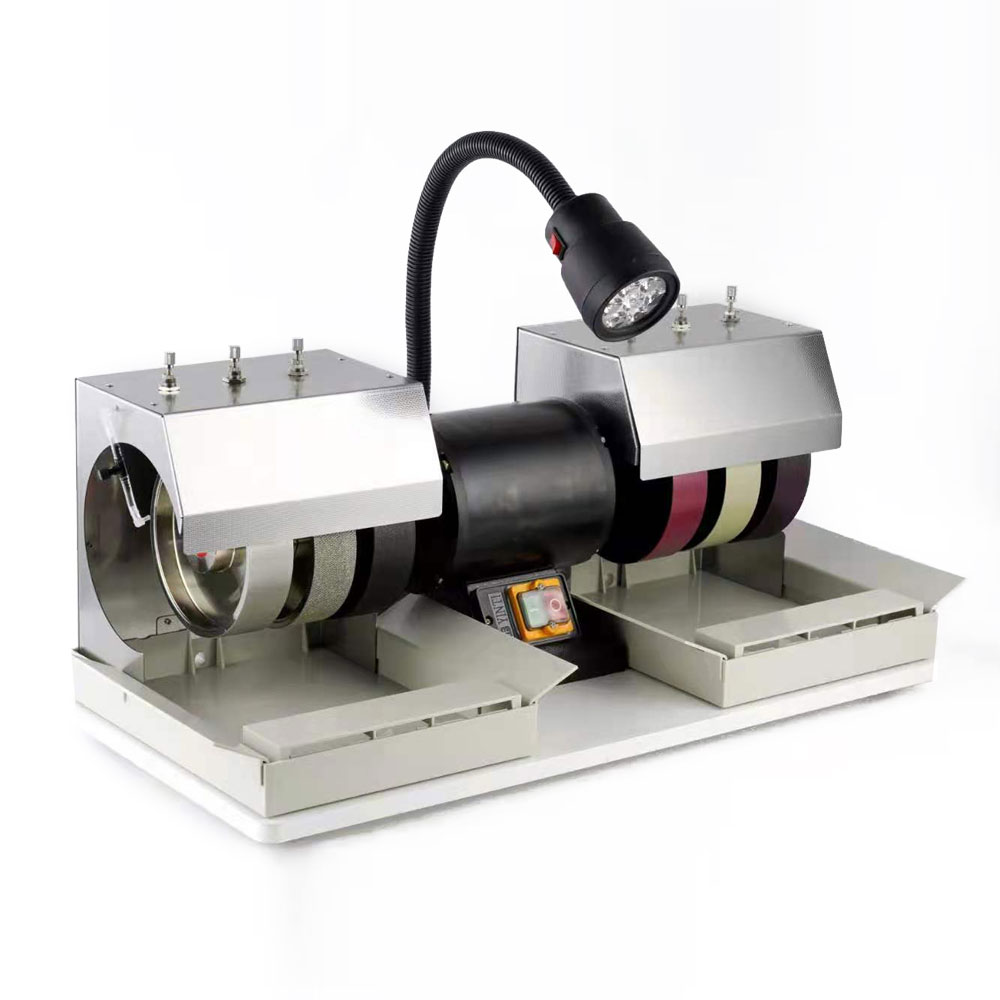

Lapidary Grinder

Above grinding wheels and polishing wheels are used on this type of lapidary grinder equipment for lapidary and other stones production to form jewelries and other decorations.

Product Desription:

Lapidary Diamond Coated Grinding wheel is Mainly used in the special-shaped processing of hard and brittle materials, For grinding or polishing lapidary stones, such as Gems, agates, jade, crystals, rubies, sapphires, etc.

Wheel Application:

01 lapidary stones raw material

02 Grind and polish stone on Lapidary grinder

03 Lapidary jewelry after grinding polishing

two Types of Grinding Wheels

Lapidary Diamond Coated Grinding Polishing Wheel with steel body

Lapidary Diamond Coated Grinding Polishing Wheel with plastic body

Whatsapp Mrbrianzhao

Specification:

Features

Specification:

4″ Wheels Size:

100*25*25.4, 100*32*25.4, 100*38*25.4

6″ Wheels Size:

150*25*25.4, 150*38*25.4, 150*50*25.4

8″ Wheels Size:

200*25*25.4, 200*38*25.4, 200*50*25.4

Grit Option: 60#,80#,100#,120#,180#,220#,360#,600#,1200#,1500#,2000#,3000#

Features

- Great for cabbing and contour grinding.

- Suitable for all conventional grinders

- Use cooling water during processing

- Longer grinding life and clean, polishing.

- They are nickel electroplated using commercial-grade diamonds uniformly throughout the entire width of the wheel, making them more durable and aggressive than silicon carbide wheels

- All wheels are made with a plastic center core, which puts less stress on machine bearings when compared to wheels with steel hubs because they are lighter, Have a good balance.

- This soft, flexible construction enables the surface of the Soft Wheel to conform to stones, eliminating flat spots and scratches

Contact Mrbrianzhao

[wpforms id=”478″ title=”false” description=”false”]