What is Dressing?

Before we can go into the whole content of "How to Dress a Diamond Grinding Wheel", you have to know what dressing means in grinding wheels. If you have read our blog about “How to True a Diamond Wheel”, you have already learned that truing and dressing are different processes. To clarify things, dressing is the process of sharpening the abrasive components of the wheel. The procedure dissolves the bond and eliminates dull abrasive grains, revealing new, sharp abrasive grains. The dressing also eliminates small particles of material from the pores of the wheel face, which helps to minimize wheel loading and can create vibration and burn marks on the workpiece.

Understanding the Dressing Process

In the manufacturing business, you're well aware that one type of tool is frequently required to ensure the optimum efficiency and longevity of other tools. Diamond dressing tools are one of the most important auxiliary tools for keeping grinding wheels true and free of particulates. Grinding tools, drill bits, chisels, and other tools with sharp points or edges are kept sharp with this treatment method.

Truing and dressing bonded diamond grinding wheels are required on occasion. This could be due to normal tool wear or high grinding loads if processing parameters are not optimized. You'll want to be able to reshape the tool and/or expose fresh diamond abrasives for whatever reason. To understand the dressing process and how it works, let us now learn the whole procedure of how to dress a diamond grinding wheel.

How to Dress a Diamond Grinding Wheel?

You might know the concept behind the dressing process. But the main point here is, do you know the proper procedure on how to dress a diamond grinding wheel? If you are unsure of what to do next, this blog post is written to guide you throughout the whole dressing process.

Grinding Wheel Dressing Steps for General Dressing Tools

Here are the methods to correctly and successfully dress a diamond grinding wheel.

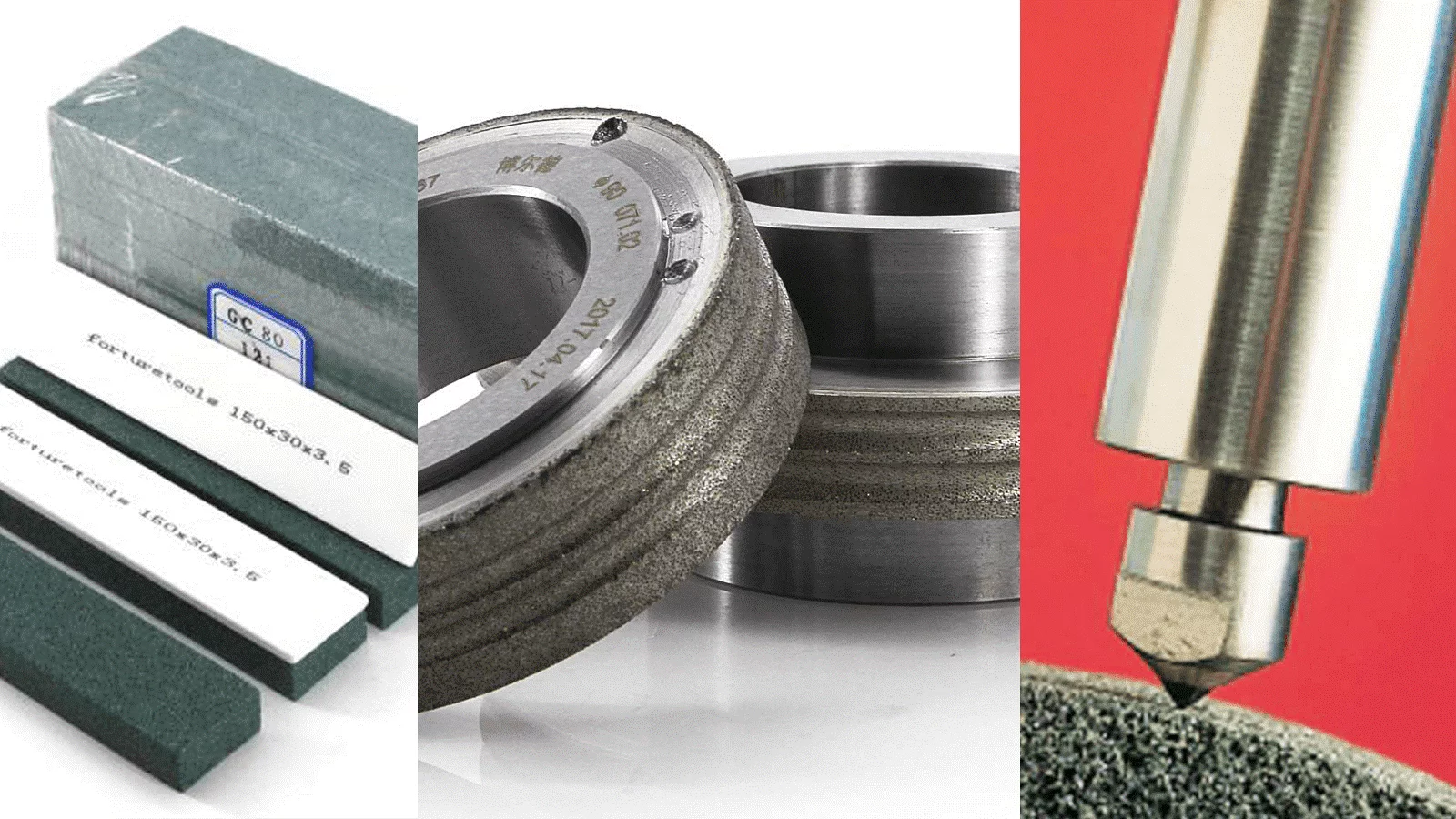

Step 1: First thing you can do is to determine the wheel's correct dressing tool. Make sure the dressing tool's grit is one or two sizes finer than the grinding wheel's abrasive surface. Also, ensure the dressing tool you purchase is the right shape for your grinding wheel.

Step 2: After that, turn off the coolant pump on your grinding machine (if it has one).

Step 3: For the third step, you may now turn on your grinding machine and let it run until it reaches its maximum RPM; depending on your desire or experience, you may choose to turn off or keep your spindle motor going. If you have a lot of truing to do, keep the motor on rather than turning it on and off.

Step 4: Next step is to apply light to medium pressure to the abrasive part of the wheel with the dressing tool; keep applying pressure until the wheel stops revolving.

Step 5: Repeat the fourth step until the dressing tool feels as though it is being pulled away from you by the grinding wheel.

Step 6: For the last step, you may repeat what you’ve done in Steps 4 and 5 depending on the state of your grinding wheel’s surface. You can repeat it if necessary (usually four to five times).

Grinding Wheel Dressing Tips Using a Dressing Stick

There are also alternative ways on how to dress a diamond grinding wheel. If you have decided to use a dressing stick, then you can follow these steps on how to dress a diamond grinding wheel.

Step 1: Start the process by selecting a silicon carbide or aluminum oxide dressing stick.

Step 2: Next step is to soak the dressing stick with a coolant. This will lead to the formation of slurry especially when it contacts the diamond grinding wheel. Why do we need to soak the dressing stick thoroughly? A wet dressing stick does not grind off easily compared to dry dressing sticks. You can also have greater control over the bond removal process and you can prevent the dispersion of dust all over the place.

Step 3: After soaking the dressing stick, you may now bring it in contact with the revolving diamond wheel. Make sure to not move the sticks sideways or it will erode the bond side of the particle. When that happens, except for a weaker particle bond. Always remember to plunge in a straight direction for a much better result.

Step 4: This is where the dressing happens. In this part, you may now feed the dressing stick aggressively into the diamond wheel to open up the wheel’s face. This is where the new layer of diamond grains is exposed.

Step 5: When the dressing wheel starts to wear out quickly, the diamond tool is finally dressed.

Important Additional Tips

- A gentle reminder, the low rpm speed control will make the wheel act softer which will cause chip clearance opening.

- If you want to expose the particle automatically, you may use an air jet abrasive stream.

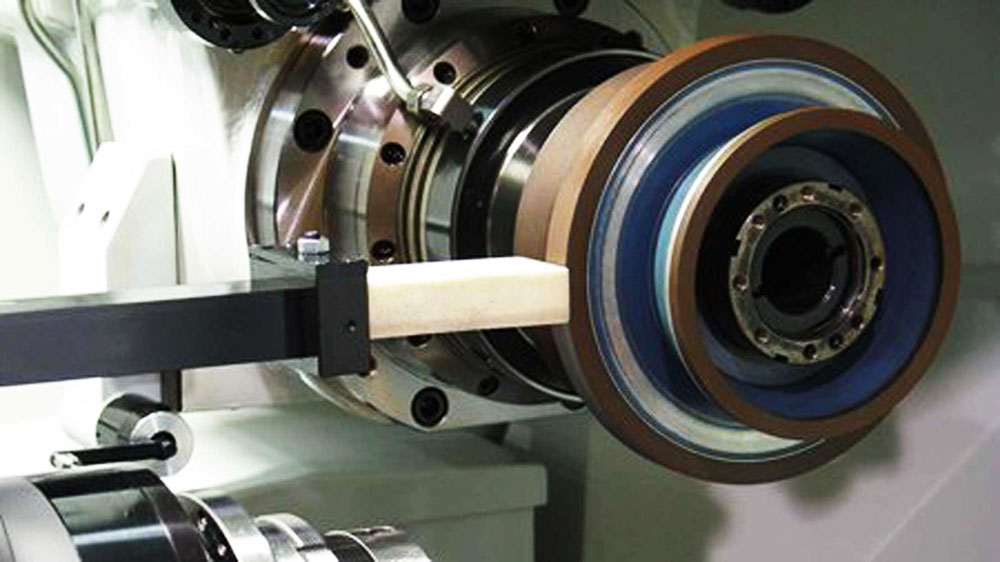

- For easy controls, you can use an automatic dressing device. This device will push the dressing wheel into the diamond wheel. Another option is to use a motor device that can be applied for dressing and truing.

- To avoid damaging the tool or injuring yourself, make sure the tool rest is at the proper distance from the grinding wheel (usually 1/16th of an inch).

- For dressing-coated diamond grinding wheels, use a 220-grit dressing stick for 500 mesh with a coarser and a wire brush. This is an effective way of cleaning out scales and swarf.

- To protect your eyes from airborne particles, always wear safety glasses.

- When working near a rotating grinding wheel, wear loose-fitting clothing with long sleeves and pull long hair back.

- Try to back off from the previous feed before inserting a new dressing tool. This is to prevent touching the previously damaged diamond particles.

- Use coolant whenever possible. Start the dressing process at the highest point of the wheel.

- Always remember to dress your diamond grinding wheel at regular intervals to prevent surface loading.

- When the diamond tool gets dull and visibly flat, try to reset or replaced the dressing tool.

- Make sure that your diamond has the right carat size. Take note that bigger diamond wheels need larger diamonds.

Why is there a Need for Dressing a Diamond Grinding Wheel?

Just like truing, dressing is very essential in optimizing the performance of the grinding wheel. In fact, a skilled mechanist that is knowledgeable of the proper dressing tools, techniques, and methodologies, can certainly improve the performance of the wheel.

To further enhance your knowledge about the concept of dressing, here are some benefits of the dressing process that you might want to know.

- The dressing is the key to achieving the best consistency and observance to its product specifications even for high-quality grinding wheels.

- Dressing minimizes vibration and improves the surface finish of the wheel.

- You need to perform dressing processes on your grinding wheels to continue producing precise and quality abrasive grinding wheels.

- You are maintaining the maximum efficiency and life of your wheel.

In the field of abrasive wheels and tools, dressing is an important practice that we all have to learn. It is not enough to know them by information from the web. Try to gain some experience on how to dress a diamond grinding wheel. Just like what others are saying, “experience is the best teacher”. This blog is intended to guide you throughout the whole diamond grinding wheel dressing process. But if you want to know more about abrasive products, visit our website at agrindtool.com. You can also check our blog post about diamond dressers and dressing tools through forturetools.com.