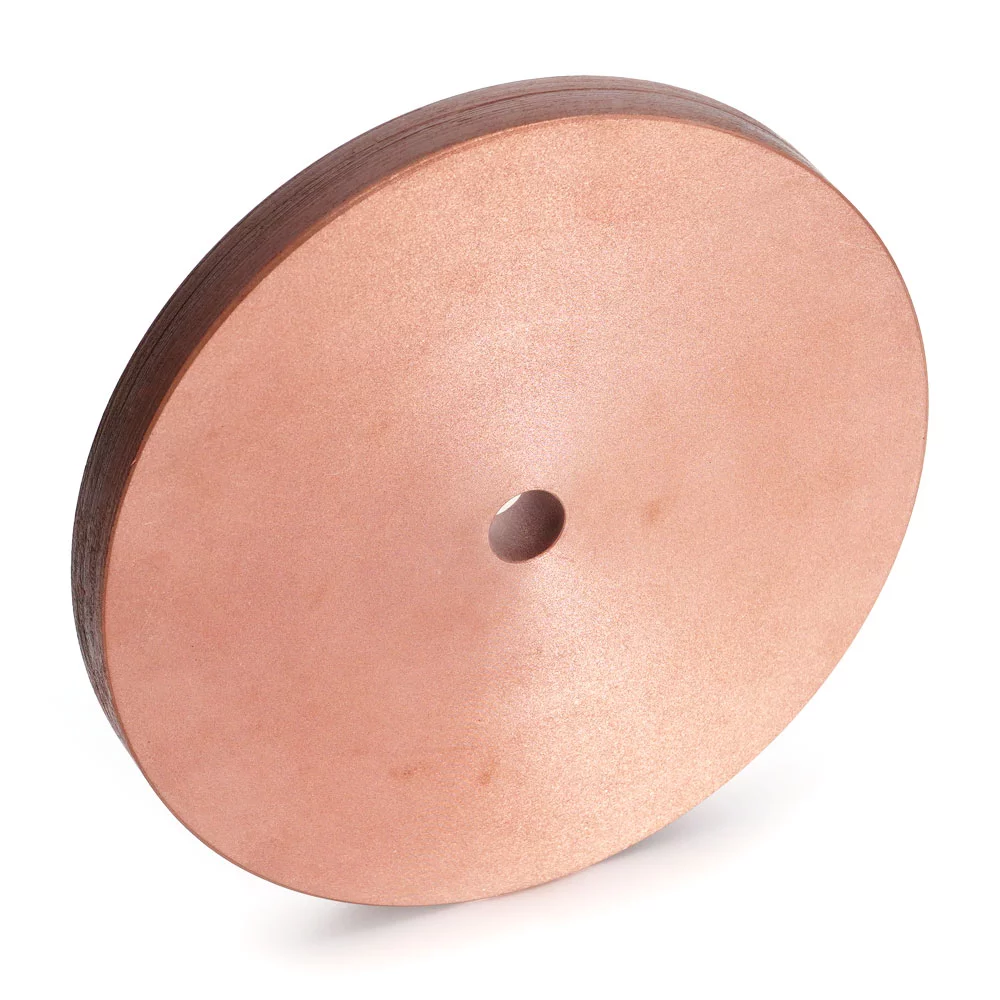

Features of Copper Polishing Lap for Lapidary Gemstones

There are numerous reasons why copper polishing laps are suitable when selected amongst other existing laps, such as ceramic and cast iron laps, fast lap & last lap, tin/ lead lap, and BATT lap. Some of these distinctive features of copper polishing lap include:

- Can be used for pre-polishing and final polishing

- Designed with high-grade Copper for perfect polishing

- Made perfectly parallel and flat to the surface to provide excellent balance and accuracy

- Can get charged easily with diamond grit or any appropriate polishing compounds

- Seen in standard 6″ and 8″ diameters with 1/2″ arbor and can be customized according to customer’s desired dimensions.

Overview

There are numerous available choices of laps for pre-polish grits. These include Bronze, BATT, Ceramic, Zinc, and Copper. All these are considered good choices. For instance, the use of a ceramic lap for prepolishing gemstones will help know that finer grits can offer less troublesome results. Another good choice that is better than copper is bronze, which is harder and offers flatter facets on hard gemstones such as corundum. Notwithstanding, copper remains a widely used lap for pre-polish grits. In this guide, we’ll be exploring what copper polishing lap for lapidary gemstones is all about, its use, and specifications.

Product Description

As the name implies, the copper polishing laps are designed using pure Copper. Gem cutters use these polishing tools for pre-polishing and final polishing. Seeing how hard they are, copper polishing laps are considered suitable to finish lapidary gemstones to the finest level. Some of these hard stones include Diamond, Rubies, Corundum, and Sapphires. In short, these polishing laps can get charged easily with diamond powder or any appropriate polishing compounds using a recharge roller.

Copper polishing laps for lapidary gemstones are great for use with 3,000 or 8,000 grit diamond that has a hole size of 1/2″ to give a fine pre-polish. A hand-charged copper lap is ideal for a pre-polish lap or cheap cutting.

Common Use

Copper polishing lap for lapidary gemstones is preferred based on several reasons relating to uses. Some of the common uses of this lap include:

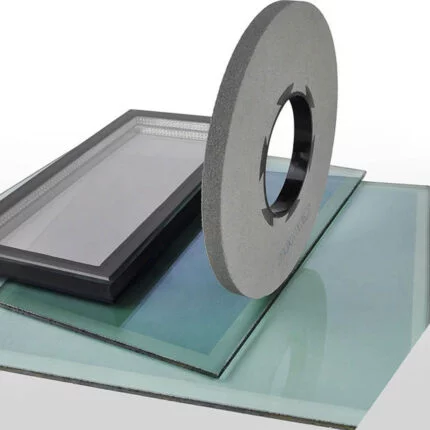

- For pre-polishing hard stones: Copper polishing lap can be used for preliminary smoothing, involving an excellent coarse polishing compound and buffing. The abrasive process of removing a small amount of the surface from gemstones is called buffing. For pre-polishing, copper polishing lap for lapidary gemstones will only remove minor scratches left on the surfaces after sanding and smoothing and not produce a bright polish.

- For the final polishing of hard stones: Copper polishing laps can be used for the final mirror finish by polishing gemstones. For polishing, harder compounds (such as rouge) are used. There is no cutting action with a compound like rouge– it only brushes the stones, moving the surface layer around to smooth the fine scratches that buffing fails to deal with.

Specifications

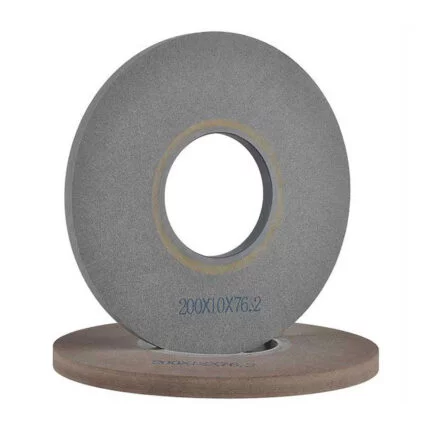

Below are the specs of copper polishing lap featuring lap diameter, hole size, and thickness:

| Copper Polishing Lap for Lapidary Gem Stones | |||

| Material | Lap Diameter | Hole size | Thickness |

| Copper | 6″ and 8″ | 1/2″ | 15-18 mm( Approx.) |

| The specification of polishing wheels for a lapidary gemstone is subject to change | |||

Summary

Lapidary is the process of cutting and polishing gemstones. For the excellent polishing of gemstones, copper is one of the best materials that can be recommended for any lapidarist. With this polishing lap, pre-polishing and final polishing can be done with ease.

Reviews

There are no reviews yet.