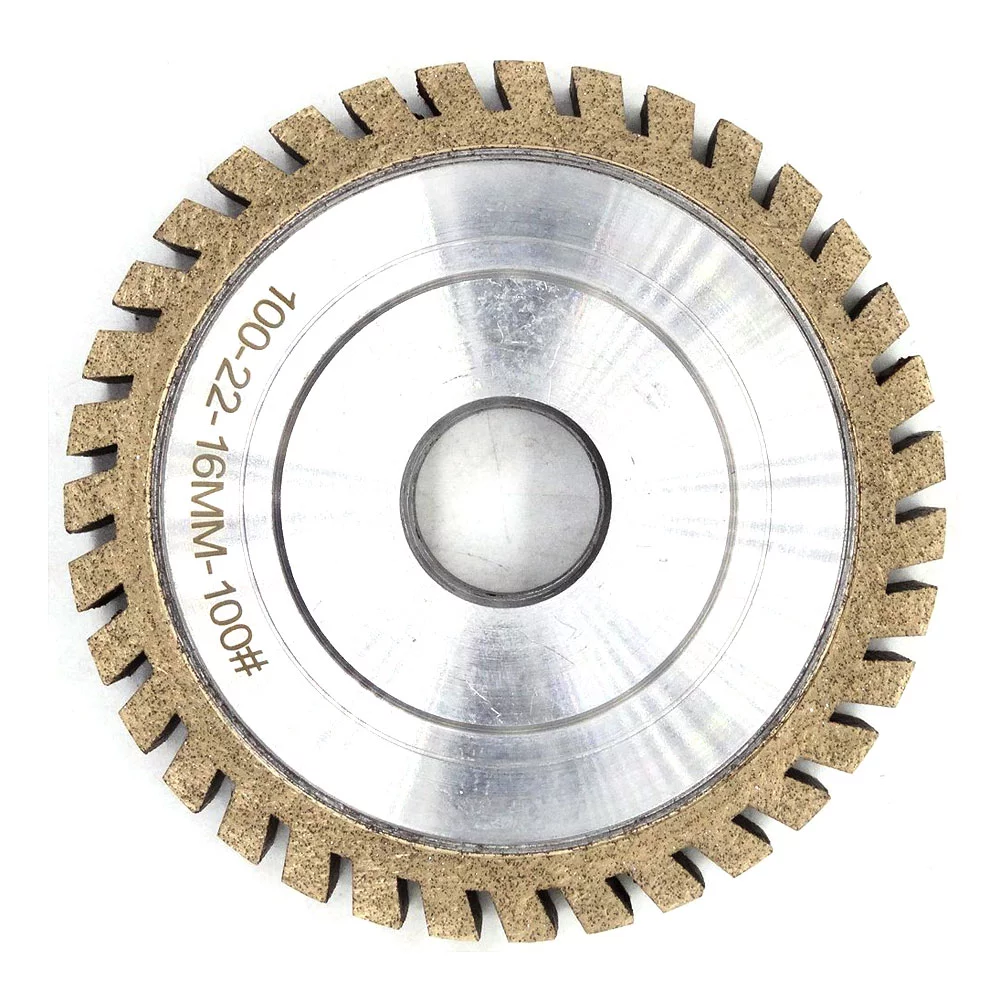

Brief Description of Peripheral Segmented Diamond Wheels:

Premium metal powder and self-produced synthetic diamond grits are fused at high temperature and high pressure to create the Peripheral Segmented Diamond Wheel. The appearance resembles a jagged edge, and this design may increase the grinding wheel’s cutting power, as well as contribute to the work of water and excretion, lower working temperature, and protect the glass from heat (burns, explodes, etc.). It is a unique grinding wheel with a diamond grain size of 80/100 # that is used to coarse grind the bevel edge of the glass.

Features:

- This product is very user-friendly

- Wheel with internal cooling.

- Dressing frequency is reduced.

- Form retention is exceptional.

- Superior surface finishes

- Enhanced efficiency

- Future-oriented

- With a solid link and less damage, you may expect a longer lifetime.

- The gullets (the gaps between the segments) collect cutting dust and keep the blade cool.

- They also provide a little flexibility to the blade, preventing fractures from forming when utilized in difficult situations.

- These blades are used for both dry and wet cutting and provide the harshest cut.

- Concrete, reinforced concrete, asphalt, and any other construction materials are appropriate for segmented blades.

Detailed Description of Peripheral Segmented Diamond Wheels:

Uses of Peripheral Segmented Diamond Wheels:

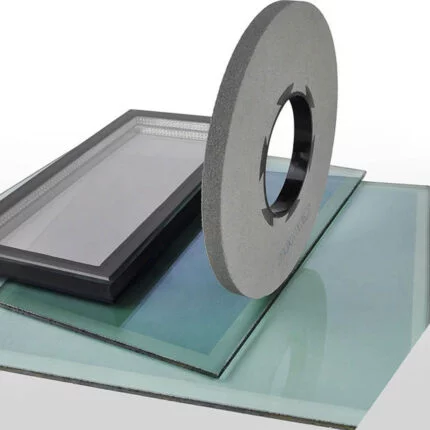

- Edge profiles are polished using the peripheral surface of Peripheral Segmented Diamond Wheels.

- The contour of the glass’s edge profile is created by diamond wheels.

- To fully polish the edge, the peripheral type composition polishing wheel immediately achieves the diamond-produced form.

- To shorten break-in time, polishing wheels may be pre-profiled using a hand-held diamond tool.

- Pencil and ogee forms, as well as flat edges, are the most common uses for peripheral wheels.

- Peripheral wheels will wear unevenly due to the diamond wheel’s position relative to the glass edge.

- The severity of this wear may be reduced with appropriate maintenance and wheel selection.

Specification Parameters of Peripheral Segmented Diamond Wheels:

These wheels are available in different grit sizes, diameters, and thicknesses. You can choose the wheel according to the nature of your work. However, if you want a customized wheel, we will be customized that for you.

| Diameter(mm) | Thickness(mm) |

| 100 | 6 |

| 100 | 8 |

| 100 | 10 |

| 100 | 12 |

| 100 | 15 |

| 100 | 19 |

| 150 | 6 |

| 150 | 8 |

| 150 | 10 |

Types of Peripheral Segmented Diamond Wheels:

-

Trapezium profile segment 1DD Huater:

This type of peripheral Segment diamond wheel is used to grind the edge of laminated glass’s “trapezium” in both straight and curved directions. A diamond layer made from a fraction of diamond mixed only on a metal base is used on peripheral diamond wheels. The edge of the glass or mirror becomes ground, but matte, after processing with peripheral diamond wheels. Glass and mirrors have a matte edge that may be erased by using peripheral polishing wheels.

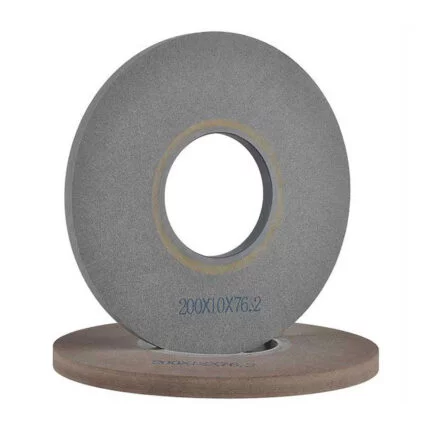

2. Pencil profile continuous 1FF Huater:

A diamond layer of a fraction of a diamond is mixed exclusively on a metal foundation in peripheral diamond wheels. The edge of the glass or mirror becomes ground, albeit matte, after processing with peripheral diamond wheels. Glass and mirrors have a matte edge that may be erased by using peripheral polishing wheels.

3. Pencil profile segment 1FF Huater:

Continuous diamond wheels are intended to grind the edge of the “pencil” of laminated glass in both straight and curved directions. A diamond layer of a fraction of a diamond is mixed exclusively on a metal foundation in peripheral diamond wheels. Segmented diamond peripheral wheels are employed for treating the edge of laminated glass or when removing a substantial amount of the glass layer. The diamond layer’s segmented structure, as well as the delivery of cooling and lubricating solution, extend the diamond wheels’ service life. The edge of the glass or mirror becomes ground, albeit matte, after processing with peripheral diamond wheels. Glass and mirrors have a matte edge that may be erased by using peripheral polishing wheels.

Things to Remember Before Using Peripheral Segmented Diamond Wheels:

- Before utilizing a diamond wheel, make sure it is in good working order (Cracked, passivation).

- The wheel should be installed in the proper location and machine according to the “coarse grinding-medium grinding-fine polishing” procedure.

- Before utilizing the wheel, it must be installed in the proper position and pass a static balancing test.

- Water is highly crucial when using a diamond wheel to grind, as it not only improves the operating efficiency but also extends the diamond wheel’s service life.

- It’s also crucial to choose the right place. Speeding up or using too much effort might harm the grinding wheel and potentially hurt the operator.

- If the grinding wheel is not sharp enough or is obstructed during the grinding operation, it should be cut slightly.

- Diamond wheels are important tools; they should not be left in disarray, and they should not be subjected to extreme temperatures. They should not be impacted by wet, erosion, or collision.

Summary:

Peripheral Segmented Diamond Wheels are used to coarse grind the bevel edge of the glass and for many other fine edges grinding purposes like marble /graphite edge grinding. These are multifunctional and it depends on the skills of the worker. Premium metal powder and self-produced synthetic diamond grits are fused at high temperature and high pressure to create the Peripheral Segmented Diamond Wheel. These are fine quality wheels with extended life and produce less noise. The gullets (the gaps between the segments) collect cutting dust and keep the blade cool. All types of Peripheral Segmented Diamond and related Wheels have been discussed with their uses. You can pick the wheel of your choice according to the nature of your work.

More customized grinding wheels are available, contact us.

[wpforms id=”4612″]

However, you also might be interested in tools like: Full Segmented Diamond Wheel for Glass Edging

Reviews

There are no reviews yet.