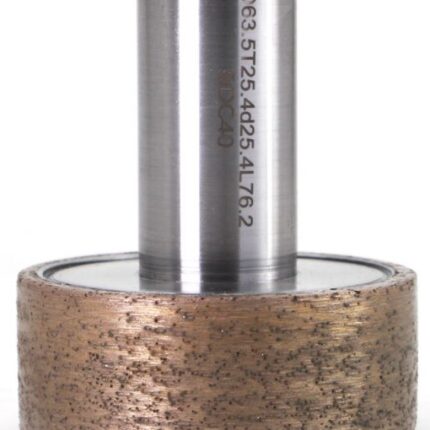

Brief Introduction of Multi-Point Diamond Dresser

Diamond Dressers are made with natural diamond and synthetic materials like CVD, PCD, and MCD. in steel shanks of various shapes for straight or form dressing. For truing and dressing of conventional abrasive grinding wheels. It is including Single-point, multi-point, chisel shape, straight, angle, and radius configurations. They are used for improving abrasive grinder performance by helping round the wheel and clean, shape or open the wheel face.

Usage of Multi Point Diamond Dresser

1. Grinding wheel correction and sharpening

2. Thinning and dressing of traditional forming wheels

3. Correction of special arcs, angles, and irregular shapes

4. When the grinding wheel is stuffed, the sharpening action when the sharpness drops is generally traditional silicon carbide, and the alumina grinding wheel is eccentric during grinding. When the uneven surface is polished, it needs to be trimmed with a diamond correction knife to make it level. Restore grinding performance.

The features for our Multi Point Diamond Dresser:

- Higher Output diamond dresser

2. Different size dresser available

3. Diamond sizes from 0.2ct ~2ct are available

Advantages of our Single Point Diamond Dresser Tools

- Supersize Pure Natural Diamond

Featured South Africa premium diamonds,single-particle ensure precision and finish of machined parts

2. Stainless Steel Shank

The shank is made of high-quality stainless steel which is more steady and durable.

3. New Welding Technology

Using a vacuum low-temperature welding process, the diamond is welded firmly and particles will not fall off.

4. Long Service Life

Diamond is bonded in cemented carbide matrix with high hardness, they have a long service life, short dressing time not easy to wear off.

More other customized diamond tools are available, contact us.

[wpforms id=”4612″]

Reviews

There are no reviews yet.