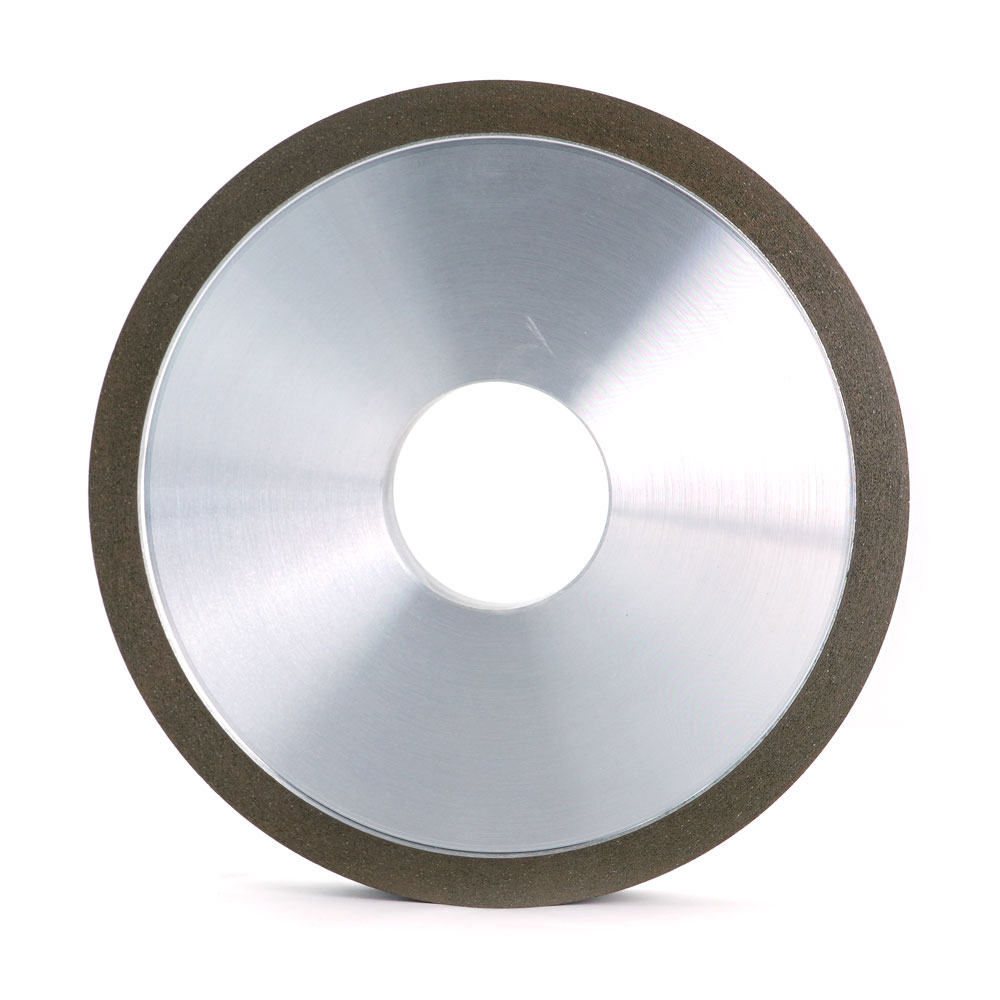

Resin bond diamond grinding wheels’ usage:

Resin bond diamond grinding wheels suit to grind carbide, hard steel, hard alloy, all kinds of serrated teeth, sharpen edges, milling cutter, Suitable for the surface grinding and outer circular grinding of cemented carbide measuring tools, tungsten steel, alloy steel. Also suit for grinding high-alumina porcelain, optical glass, agate gem, semiconductor material, stone, etc.

Resin Bond CBN Grinding Wheels are mainly used for machining high-speed steel, cast iron, and so on.

Resin bond diamond grinding wheels’ Feature:

●Great surface finish accuracy due to its high efficiency and precision mechanism

●Sharp-cutting feature even for rough workpiece surfaces or materials

●Low heat generating feature to avoid burning of the workpiece or materials

●It can be used for various odd shapes and can be easily manipulated

●Has its certain elasticity and is conducive to improving the roughness of the workpiece surface

When it comes to fields of cutting, grinding, and polishing, we always look for the best available material in the market. If you are into sharpening grinding and polishing surfaces, Resin bond diamond CBN grinding wheels might be the perfect tool for you.

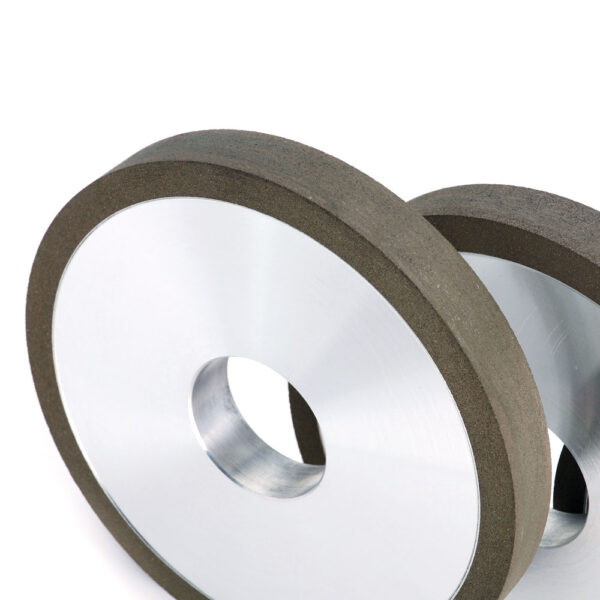

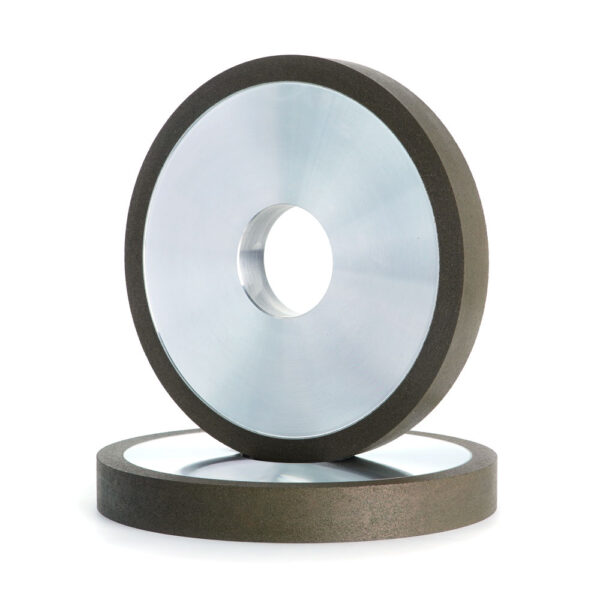

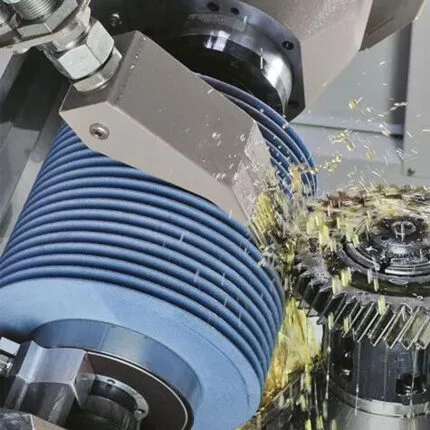

Resin bond diamond grinding wheels are mainly used for sharpening, grinding, polishing carbide tools, ceramics, glass, steel, iron, cutter steel, and other hardware tools. It is available in flat, bowl-shaped, cup-shaped, and even cylindrical-shaped. There are many types of resin bond diamond grinding wheels that are used for a specific application. Resin bond diamond grinding wheels are commonly applied for grinding carbide-tipped and inserted tooling such as cutters, saws, end-mills, and reamers. They are also utilized for grinding precision operations on carbide wear parts, carbide dies, and rolls. When are they used specifically? Resin bond diamond grinding wheels are the best used for precision finishing on ceramics, grinding tungsten carbide, and for ceramic thermal spray coatings. Surface grinding, OD grinding, Center-less grinding, Tool grinding, fine grinding, double-disc grinding, and slot grinding are just some of the grinding types you can apply for resin bond diamond grinding wheels. When it is combined to resin bond CBN grinding wheels, higher grinding efficiency can be done especially to speed steels, die steels, and superalloys with a hardness greater than HRC 50.

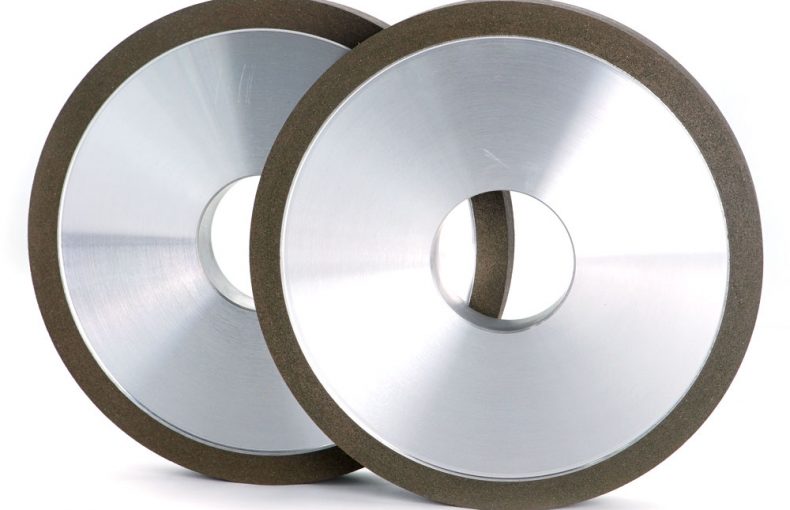

Resin bond CBN grinding wheels are used for grinding steel which should have 45Rc strength to ground the steel effectively. The good thing about this wheel is that it does not react to iron. Sample materials are tools steels, hardened steels, and cast irons. Is resin bond CBN grinding wheels worth our money? Resin bond CBN grinding wheels are very much applicable to manufacturing key parts of automobiles, engines, gearbox, steering pumps, air conditioners, and bearings, which are composed of 11 different parts from 9 different materials. Now, auto manufacturers are looking for a grinding wheel that can provide different performances considering the big difference in the hardness of the key parts and the materials to be used. With this, the resin bond CBN grinding wheels have come into the picture and have been popularly utilized in the auto-manufacturing industry as it increases the efficiency of the manufacturing process and reduce the cost in like the frequent replacement of grinding wheels. This is because resin bond CBN grinding wheels can meet the grinding requirement of three different materials and mechanical parts. Impressive right?

Resin bond grinding wheels are made of resin bond products which are composed of resins and fillers pressed under heat and pressure which are easily dressed for straight forms, angle forms, and special radius forms. Resin bond grinding wheels are not only good for industrial fields and hardware, but it contributes a lot of things to the modern time of machinery and industrial technology. Compared to other bond types, resin bond diamond and CBN grinding wheels have good self-sharpening, high efficiency, low heat generated during grinding to avoid burning workpiece, have a sharp cutting mechanism, and are very easy to manipulate. And, it would be a great factor if you know the ideal grinding wheel suitable for your desired results.

Industries Resin bond diamond grinding wheels used in:

Tool Industry

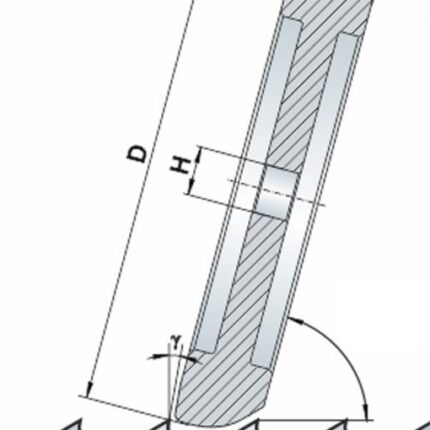

This resin diamond CBN grinding wheel is best used for grinding digital controlled cutting tools such as high-speed steel, tungsten carbide, mill, reamer, and other stainless drills. The common specification type of resin diamond CBN grinding wheel is the 1A1 type. 1V1, 12V9, and 11V9 types are also some popular types of resin diamond CBN grinding wheels. You may visit our website for the universal specs of each type.

Glass Processing Industry

If you are into glass processing, resin bond diamond wheels can also be used for production. Resin bond diamond wheels can be used for glass edge grinding especially for Resin Wheel for Beveling and Edging. The grain size can be 200# – 240# mesh. While the diameter can be 100mm, 130mm, and 150 mm depending on the client’s machine types.

Circular Saw Industry

When it comes to good self-sharpening, sharp cutting, and high-efficiency rates, resin bond grinding wheels should be your next asset. It is highly recommended by most saw makers due to its high efficiency and grinding precision to any workpiece. Resin bond diamond CBN grinding wheels are a popular grinding wheel use of woodworking tools. Due to its precise grinding mechanics, it can grind the top, face, and side surface of the circular saw blades made of tungsten carbide or other metals. Not only that, but you can also use it for woodworking drills and end mills. The popular specification of the resin bond grinding wheel is the 4A2 type which has the universal spec D: 50-250, W: 3-15, X: 2-10.

Cutting Industry

If you will be cutting ceramics, carbide, magnetic materials, glass, steel, and cast iron, resin bond diamond CBN grinding wheels is the best tool to use. This grinding wheel is composed of a compounded steel plate and a super abrasive work layer. This grinding wheel is best used for deep grooving and cutting because of its high strength and rigidity. Popular models are the 1A1, 1F1, 1A1R, 3A1, 14F1, etc.

Thermal Spray Industry

For surface treatment, layer protection, and mechanical parts repair, thermal spray coating is a popular method to use especially with resin bond grinding wheels. Its coating mechanics makes it worth spending since it will improve the wear resistance and will prolong the life span of the mechanical parts. Industrial fields that use resin bond grinding wheels are common machinery, shipbuilding, steelmaking, petroleum, and aerospace industries. Not only does it worth spending for, it undeniable results will create a bigger impact on the processing and economic benefit. Common product specifications of resin bond grinding wheels for thermal spray are 1A1, 14A1, and 3A1 tyle.

Woodworking Tools

Resin bond grinding wheels can also be used for woodworking tools which are utilized for processing woodwork drills and mills. There are various woodworking grinding wheels in the market. Some of these popular grinding wheels are the top, facet, side, and profile grinding wheels. The common top grinding wheels type that is available in the market are the 6A9, 6A2 types. They can be composed of single, dual, or triple quad grits to ensure their high efficiency that can finish both roughing and grinding processes. Common machine types you can use for this grinding wheel are Vollmer, Akemat, Utma, and Walter. If you are into grinding circular saws, face grinding wheels can be the best tools to use. Some popular specifications of this grinding wheel are 4A2, 12V9, and 12V2. On the other hand, side grinding wheels are used for CNC lathes machines since it ensures uniform wheel dimensions. Often used types for this grinding wheel are AKE, 3A1, and 1A1. The body can be made up of steel or aluminum.

Resin bond grinding wheels are becoming quite popular in mechanical production. Most industrial fields that utilize resin bond grinding wheels are German-Swiss and Chinese grinding machines. This only proves that resin bond grinding wheels will be the next top-selling tools for workpiece machinery. If you are to purchase resin bond diamond grinding wheels or resin bond CBN grinding wheels, you have to tell the product owner about the type and structure of your grinding machine, as well as the type of workpiece to be ground. This will prevent unexpected conflicts with the grinding wheel and assure the best abrasive tool for your project.

What are the best features you can expect for our resin bond diamond and CBN grinding wheels? Our company always assures the best quality product for our clientele. This is why the resin bond diamond and CBN grinding wheels are equipped with so many features like excellent sensitivity, so they can be easily reconditioned. Another awesome feature of our resin bond diamond and CBN grinding wheels is their high efficiency and great surface finish accuracy. This is the reason why most companies that need surface treatments and mechanical parts repair turn to resin bond grinding wheels. Due to its available models, it will definitely work on odd shapes. And we can assure you that any workpiece will not be burned. These are some of the great things you can expect in resin bond diamond and CBN grinding wheels. It will not take much longer for it to become the next generation grinding wheel due to its rising popularity and multiple utilization.

Resin bond diamond and CBN grinding wheels can be of greater use to so many industries like the carbide cutting tool industry, ceramics, glass processing, quarts, thermal spray, and other specialty industry. The only challenge here is the production process and how you manipulate them.

To better understand and enhance your knowledge about resin bond grinding wheels specifically the resin bond diamond grinding wheels and resin bond CBN grind wheels, you can visit our website (INSERT CLIENT’S WEBSITE). We can assist you along your resin bond grinding wheels journey and have a more successful production later on.

Popular specification of Resin Bond Diamond Grinding Wheels:

More customized grinding wheels are available, contact us.

[wpforms id=”4612″]

Reviews

There are no reviews yet.