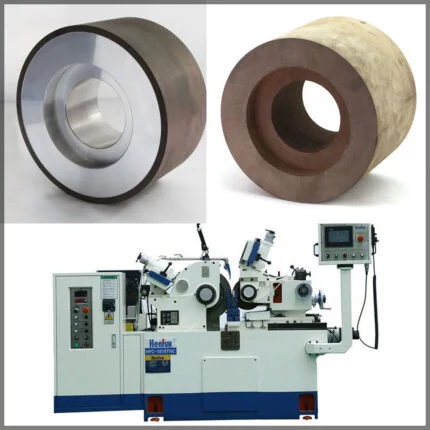

For crankshaft grinding, a Vitrified CBN grinding wheel is the best option. Vitrified CBN Crankshaft grinding wheels are innovative tools with grinding features that are mainly used in industrial fields like automotive, aircraft, aerospace, truck, diesel, etc. especially those who need regrinding of pins and bearings. Crankshaft grinding wheels can be corundum or aluminum oxide type of grinding wheel or a CBN type of grinding wheel. On this product page, we will be focusing more on Vitrified CBN Crankshaft Grinding Wheel, its features, applications, and detailed descriptions. This crankshaft grinding wheel has the latest advance in abrasive grains and vitrified bond technology which makes it a popular choice for grinding.

Features of Crankshaft Grinding Wheel:

- Highly-Functional Parts. Each part of the crankshaft grinding wheel is designed to have a different hardness that meets a certain demand in the application.

- Highly-efficient. Designed with high precision, accuracy, and efficient grinding performance.

- Sensitivity control. Highly sensitive in its control which prevents burn when grinding.

- High precision mechanics. It is suitable for high-efficient, heavy grinding of Crankshaft pin grinding, Journal grinding.

- Quality structure design. It is designed to give maximum life, withstand any wear-outs, and provide excellent form holding.

Detailed Description on Vitrified CBN Crankshaft Grinding Wheel

Vitrified CBN Crankshaft grinding wheel belongs to super hard grinding wheels that have great advantages and applications. It is highly commendable for preventing grinding burns which is very important in the shoulder of the crankshaft.

-

Product Specification:

Vitrified CBN crankshaft grinding wheels are mainly used for automotive, motorcycles, diesel, gasoline, and many more. Materials that can be used for this tool include cast iron, carbon steel, alloy steel, bearing steel, etc. This crankshaft grinding wheel is equipped with various high-precision CNC crankshaft grinding machines that are suitable for highly efficient, heavy grinding, pin grinding, and journal grinding.

Here’s a popular product specification of a crankshaft grinding wheel in the market. Check the model dimensions and sizes. The general wheel speed is 80 m/s – 120 m/s. Designs can be customized also depending on the client’s request.

| Model | D (mm) | T (mm) | H (mm) | X (mm) |

| 1A1 | 500

22 19.5 |

20 | 203 | 5 8 10 |

| 1A1 | 203 | 5 8 10 | ||

| 1A1 | 203 | 5 8 10 | ||

| 1A1 | 600

19.8 20.5 |

35 | 132 | 5 8 10 |

| 1A1 | 132 | 5 8 10 | ||

| 1A1 | 132 | 5 8 10 | ||

| 1A1 | 650

43.5 44.5 50.5 |

40.5 | 132 | 5 8 10 |

| 1A1 | 132 | 5 8 10 | ||

| 1A1 | 132 | 5 8 10 | ||

| 1A1 | 132 | 5 8 10 |

Comparison of parameters between CBN wheel and corundum grinding wheel

| Corundum Grinding Wheel | CBN Grinding Wheel | |

| Workpiece life | 20000 pieces | 100000 pieces |

| Dressing | 10 pieces | 300 pieces |

| dressing time | 1 min | 4 min |

| Linear speed | 45m / s | 90m / s |

| RPM | 1200 rpm | 2500 rpm |

The case of Vitrified CBN Grinding Wheel for Journal (Diesel engine)

| Application Parameters | |

| Workpiece | Truck crankshaft: |

| End face ø90.4mm/Journal outer circle ø74mm | |

| Material | 42CrMoA, HRC 52-58 |

| Machine | NAXOS UNION |

| Grinding parts | Journal end face, rounded corners, and outer circles |

| Cooling fluid | Oil |

| Grinding way | Cut into the mill |

| Grinding wheel | 1VG1L1 650- -39.6- -6- -3.5 NB151 |

| Dressing wheel | CNC electroplating dresser roller SG 71P-150-1.2 |

| Grinding parameters | Linear speed Vc=95m/s |

| Grinding allowance: | |

| outer circle ae = ø1.2mm, end face ae = ø0.5mm | |

| Dressing parameters | Linear speed VR=85m/s |

| Dressing quantity aed=15*2+ 1 * 2 um | |

| Dressing speed ratio qd= + 0.89 | |

| Grinding performance | Maximum material removal rate Q’wmax = 94.7mm³/mms |

| Grinding time TG = 10 min (40% efficiency improvement) | |

| Dressing frequency | |

| mT=210 journal/ Dressing(50%life improvement) | |

Common Shapes of crankshaft grinding wheels:

The shape of the crankshaft grinding wheel is very important to fit the hub, to have proper clearance, and face width for grinding. Here are common shapes used for crankshaft grinding wheels:

- Hub

- Straight

- Recessed 1 side

- Tapered

- Recessed 2 sides

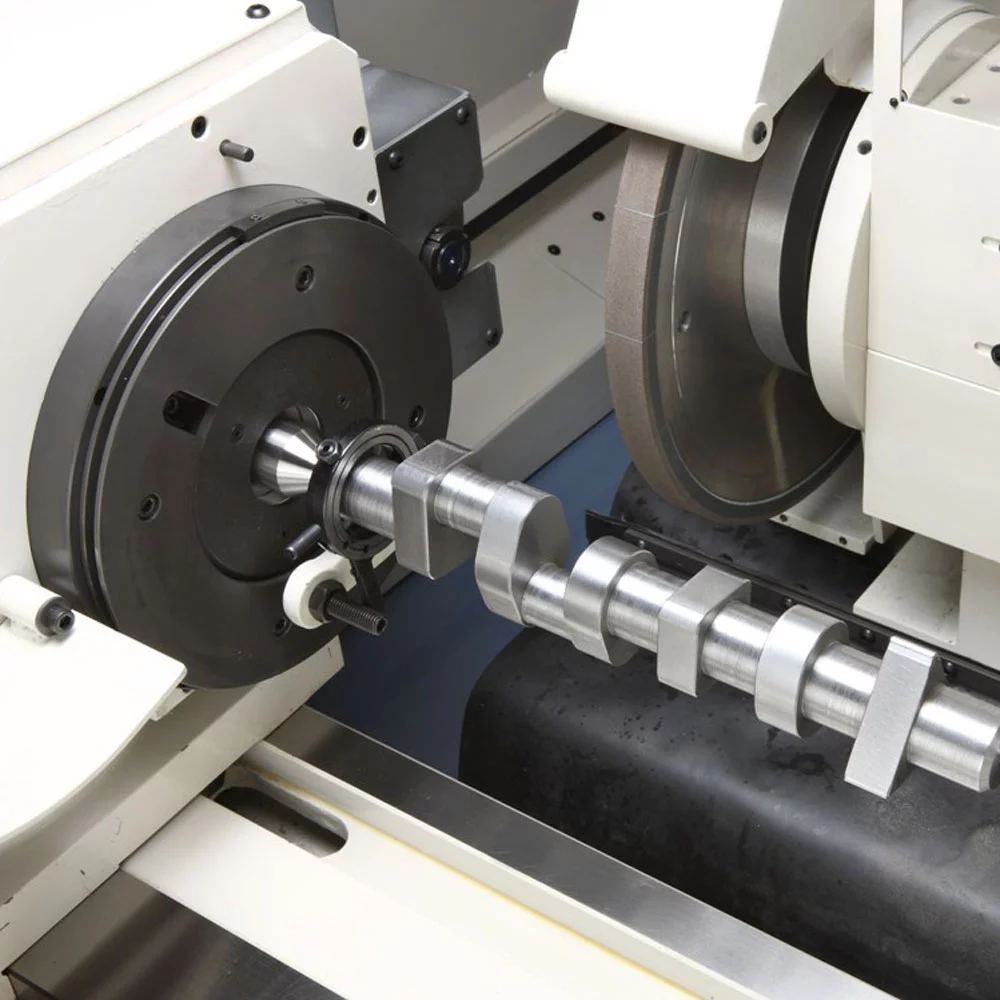

Main Parts of the crankshaft to grind and regrind:

- Main Bearing

- Rod Journals/ Crankpin Journals

- Flywheel Flange End

Application of Vitrified CBN Crankshaft grinding wheels

Vitrified CBN crankshaft grinding wheel has CBN abrasive that has superior heat stability which provides excellent performance in super high grinding to process crankshafts processing. Here are some applications of Vitrified CBN crankshaft grinding wheels in various fields and industries.

- Crankshaft grinding. Specialized in AMC Berco machines.

- For automobiles, tractors, vehicles industry

- Precision Machining and Automotive Engine.

- Has been widely used in the processing of hydraulic tappets, glibs, machine tool parts, bearing, and cutting tools.

- It is also used for high-speed grinding. This is why the bond quality, adhesives, and the materials used for the core are carefully designed for safety.

-

Why Vitrified CBN grinding wheels are necessary

This crankshaft grinding wheel is the most recommended tool for automotive, motorcycle, diesel, and other industries because of its large advantages and benefits.

- This crankshaft grinding wheel has 30-50% hardness and balance performance of the wheels which is higher than the standard type.

- Very durable and wear-resistant with its thickness deviation of not more than 0.2 mm. On the other hand, the parallel tolerance of two ends is not more than 0.1 mm.

- It is designed to hard various hardness levels which can meet specific demands in the application.

- The shoulder region is the surface grinding operation while the grinding of the pin is the cylindrical grinding operation. This is very important for a wheel to perform efficiently.

- Includes the latest advances in abrasive grains and vitrified bond technology.

- It has longer dressing intervals and tool life.

- It has a consistent surface finish and high-profile stability.

- It can reduce thermal and mechanical damage to the workpiece.

- Has good self-sharpening ability and can grind a large number of materials.

- It has a high grinding ratio and needs a sufficient supply of coolant in the grinding process.

- It uses a diamond rotary dresser for dressing large scale of production.

-

Crankshaft Grinding Wheel Tips

Selecting the correct product specification is very important to know if the crankshaft grinding wheel suits your machine and other application.

Grinding Wheel Selection

- Choose the appropriate crankshaft grinding wheel according to your application. If you will use it for cast iron, then note in mind that it won’t be that effective on a high-performance type of crank. One wheel cannot do all work at once. Check the variety of abrasive grains, grit sizes, hardness, structures, and bond modifications.

- For cast-iron crankshaft grinding wheels, choose a 35Rc or less Rockwell hardness that can be used on journals.

- For a more versatile crankshaft grinding wheel, better choose a high-performance wheel. Wheels that are domestic, import, or high-performance crankshafts will be good to use. It could be made up of cast or forged steel and nodular iron. Crankshaft grinding wheels like this can remove more materials, can load less, and create a better shape for a longer period of time.

- For diesel crankshaft grinding wheels, choose a 35Rc or more hardness that can be used for journals. Vitrified CBN crankshaft grinding wheels are very ideal for materials such as diesel, high-performance, industrial, and billet steel crankshafts.

Grinding Techniques

After selecting the right wheel, follow the steps carefully while doing the grinding process

- Inspect damages or cracks in the wheel before mounting it. You may do it by thorough looking or by using “Ring Test”. To know if a vitrified crankshaft grinding wheel is of good quality, there should be no cracks and should give off a clearer ringtone when tapped with a wooden or plastic mallet. Bad quality crankshaft grinding wheels give off a dull sound instead of a clear one.

- Checked the maximum operating speed in RPM against the actual RPM in the spindle which will drive the wheel. Use a tachometer and check the speed of the spindle from time to time to ensure consistency throughout the process.

- Pay attention to the condition of the flanges. The flanges must be flat and have an equal diameter with full contact on the sides of the wheel. Use a new blotter every time you mount the wheel.

- Make sure to balance the grinding wheel every time to achieve the best results. To balance the wheels, install the crankshaft grinding wheel on the center and snug the cap screws. Do not tighten the screws. Mount the wheel on a balancing arbor, then place it on the balancing stand.

- The wheel position should be at 12:00, 3:00, 6:00, and 9:00 for it to be balanced. Regularly check the wheel’s position to maintain its balance.

- Install the crankshaft grinding wheel on the machine. The truing process is also necessary to clean up the grinding faces and sides. After that, remove the wheel and recheck the balance. You may adjust the weight if necessary.

Vitrified CBN Crankshaft Grinding wheels are becoming more and more popular these days with their extensive application and contribution to the modern mechanical industry. Obviously, there are lots of advantages and benefits in its usage with its high efficiency, high precision, low grinding cost, and wear-resistant features.

More customized grinding wheels are available, contact us.

[wpforms id=”4612″]

Reviews

There are no reviews yet.