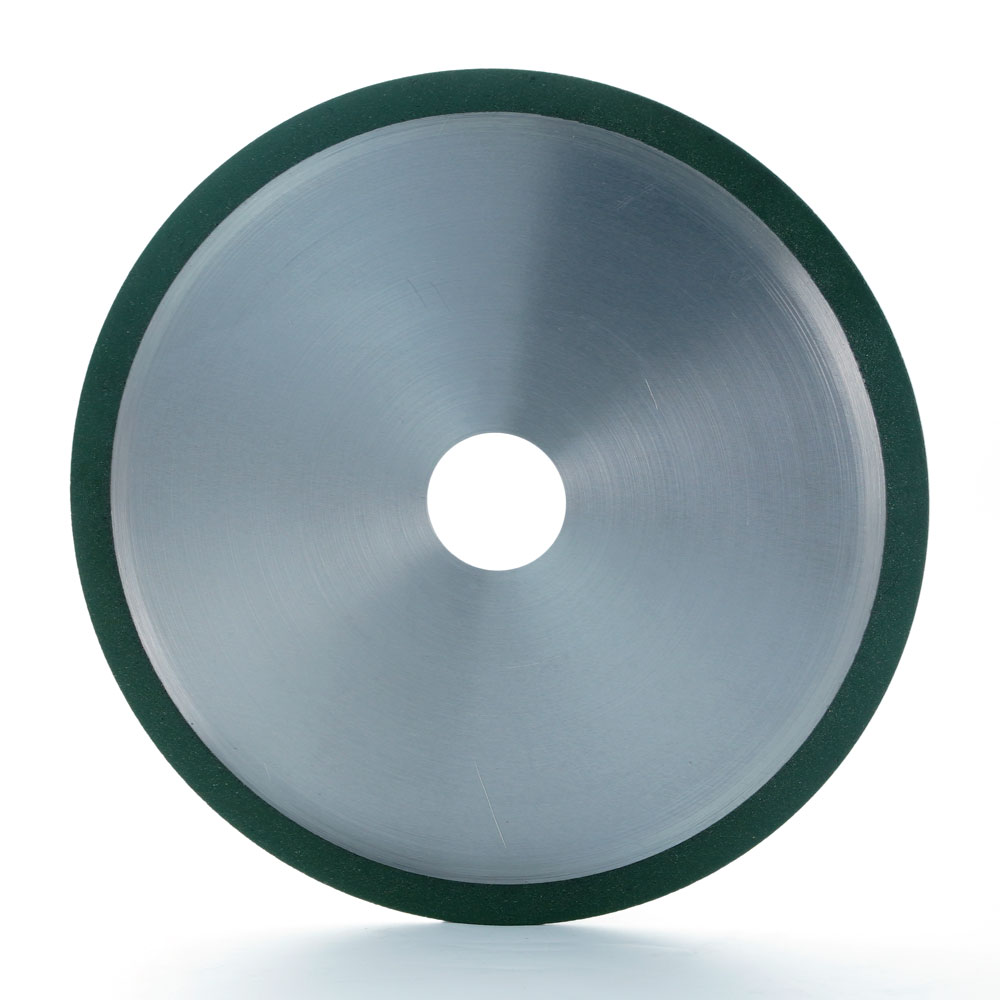

Resin Bond Cutting Wheels Brief Introduction

The resin bond cutting wheel is of two types, including resin bond diamond cutting wheel and resin bond CBN cutting wheel. The former is used to cut carbides, ceramics, exotic metals, and other hard, brittle, delicate materials. The latter is used to cut hard steels above Rc 50 at an incredible speed.

Advantages of diamond CBN resin bond cutting wheels:

- Highly efficiently cutting performance

- Suitable for both wet and dry cutting operations

- Feature low heat generation, no burning, and long tool life

- Cost-effective for every potential buyer

- Low roughness of workpiece surface

Overview

For every application, knowing the best cutting wheels will make work not only easy but also incredibly efficient, offering needed precision cutting. As an industry, priority should inflexibly be placed on getting a fine blade bond type with high quality, which can offer clean and fast operations while working on specific workpieces

Resin bond cutting wheels are characterized by great serviceability when needed in places such as automotive shops, medical manufacturing industries, tool shops, construction sites, etc. For those looking for cutting wheels that could satisfy their needs as far as cutting material is concerned, these wheels are ideal recommendations. So, it would be of immense assistance to every potential buyer to discuss the resin bond cutting wheels, their various types, common features, peculiar applications, and other necessary information.

Resin Bond Cutting Wheels

Resin bond cutting wheels remain a remarkable choice for everyone that seeks standard cutting wheels designed to meet several cutting requirements. Experts in cutting and grinding wheels acclaim that resin bond is the most versatile among all existing bonding systems.

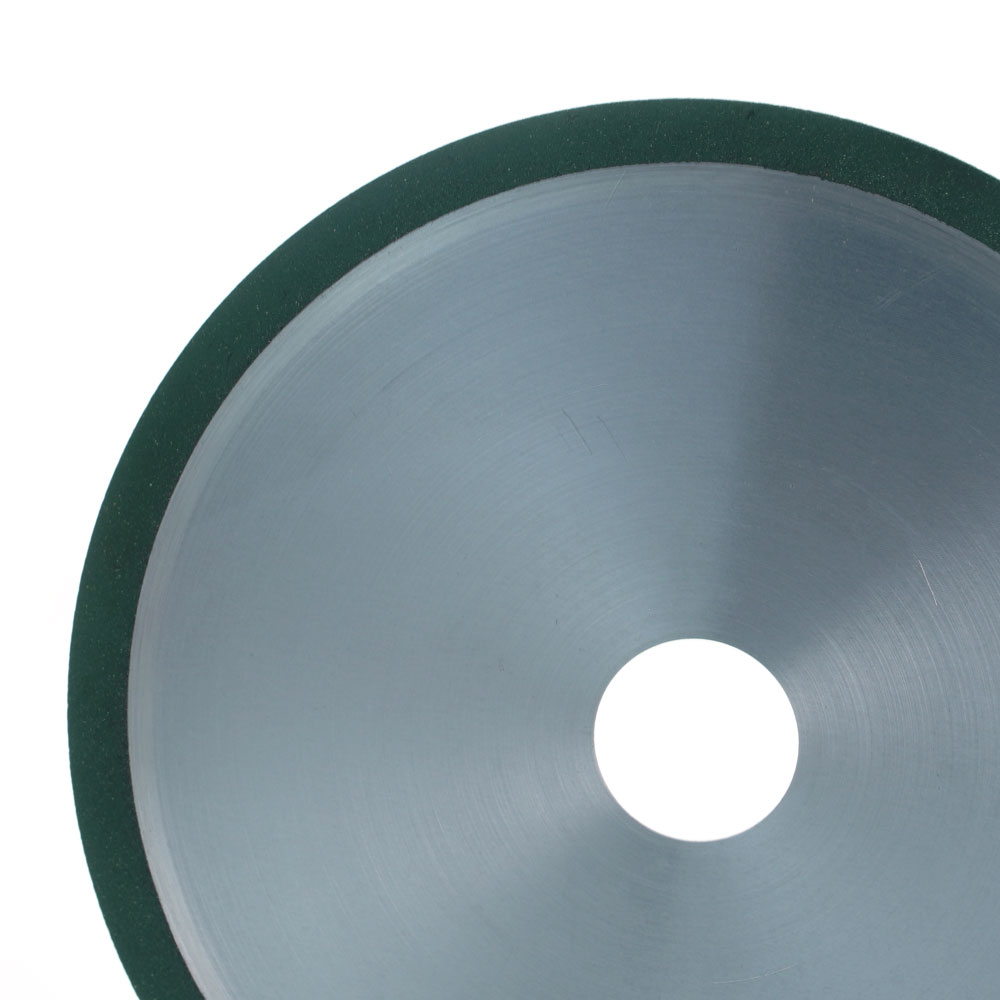

These cutting wheels are designed by experienced engineering teams to fit into specific cutting applications. Besides, the resin bond cutting wheels come with several benefits. They are characterized by self-sharpening capabilities and high cutting efficiency. It’s great to know that resin bond cutting wheels enhance low in-feed forces due to the degree of elasticity. With this, a cool running and smooth cutting are well provided and accompanied by superior performance and finishes.

Moreover, resin bond cutting wheels feature heat resistance and increased wear resistance. These are great features that impressively contribute to the lifespan of the tools and ensure that there is an extension of the time between dressing and truing.

Resin bond cutting wheels can be formulated for dry and wet cutting based on the material, application, and requirements if rightly applied. Resin bond cutting wheels are one of the best precision cutting tools for multiple different material types, including (but not limited to) tungsten carbide, Inconel, stainless steel, high-speed steel, PCD & PCBN, and ceramics.

Main industries applied:

1, Tungsten steel rod, a drill bit (bar sectional

cutting), PCB board micro-drill bit, die tip, electrode rod, Gong knife, the shuttle of the textile industry, machine tool journal, machine tool axis, etc.

2, Optical glass, including camera lens, microscope lens.

Magnifier lenses, telescope lenses, spectacle lenses, etc.

3, Valve rods in automotive engines

4, For superfine sharpening stone dry slicing

5, For Magnetic Material Processing

6, For Cutting Slots of Brake Pads

7, For the Circuit board

8, for sapphire processing

Types of Resin Bond Cutting Wheels

There are numerous types of resin bond cutting wheels. Some of these include:

- 1A1

- 1L1

- 14A1

- 1FF1

- 1F1

- 1EE1V

- 1V9

- 1A6Q

- 1A1R

- 1E6Q

- 14E6Q

- 14EE1

- 14E1

- 1DD1

- 4B1

- 1A8

Features of Resin Bond Cutting Wheels

Resin bond cutting wheels come with numerous benefits, making several industries prefer them to other tools. These beneficial features include:

- Highly efficiently cutting performance: Resin bond cutting wheels are known for their versatility and are recognized as highly efficient wheels. This implies that they can complete tasks faster for pipe fabrication, shipbuilding, welding preparation, railways, and construction.

- Suitable for wet and dry cutting operations: Resin bond cutting wheels are typically used for deep cutting. Even though dry cutting can lead to shallow cuts, with resin bond and adhering to proper cutting steel, users can impressively achieve deep cuts.

- Self-sharpening capabilities, long tool life, low temperatures: Resin bond cutting wheels can handle an extended use time. This can be traced to their capability to sharpen themselves and ensure low temperatures during the cutting operation. Besides, users won’t experience any difficulty dressing cutting wheels that use resin bonds. The wheels are also less susceptible to overloading.

- Multiple applications: Resin bond cutting wheels feature common applications, including cutting electrical carbon products (such as ferrite, carbide alloys, ceramics, and semiconductors).

Applications of Diamond CBN Resin Bond Cutting Wheels

Resin bond is produced from the combination of abrasive grit and a phenolic resin. Before the resulting compound is baked in an oven, it will first be molded to shape. The outcome of this is a tough cutting wheel with impressive resilience to withstand impacts. The manufacturers of cutting wheels can make the properties of the finished cutting wheel suit a wide variety of applications.

Some of the reasons numerous customers from different industries keep on asking for resin bonds can be traced to its shock-resistance, excellent surface finish, and low maintenance. Besides, in the world of super abrasive products, the resin bond diamond and CBN cutting wheels are the most commonly consumed tools currently. This is because they offer chip-free cutting; cut faster; have more precision; ensure minimal dressing; offer a smoother Finish.

Resin bond cutting wheels are of two different kinds: resin bond diamond cutting wheels and CBN cutting wheels. Each has its peculiar applications. Notwithstanding, on the general sphere, the applications of resin bond cutting wheels include quartz tubing rods, pyres tubing & rods, ultra-hard ceramics, ceramic tubing & rods, carbide, ultra-hard steels & metals.

Note: Experts see resin bond as the softest of all the existing bonds used from time to time in applications where a minimum amount of chipping and smooth surface finish are required.

Diamond Resin Bond Cutting Wheels

Resin bond diamond cutting wheels, which can also be referred to as dicing blades, are characterized by vertical consumption and are capable of reducing grain deformation occurrence and improving the efficiency and quality of cutting on brittle, delicate, and hard materials. These materials include carbides, ceramics, and exotic metals, where improved surface finish or low heat generation is expected. Besides, they are a kind that requires higher speed.

These cutting wheels are commonly used in industries such as the carbide cutting tool industry, ceramics industry, glass industry, quartz Industry, thermal spray industry, etc. They feature a high-strength & high rigidity steel core and abrasive layer, engaging them in multi-cutting and deep cutting. Resin bond diamond cutting wheels are suitable for cutting different materials, including ceramics, carbides, glass, stone, quartz, Silicon, and other specialty materials

Features of Diamond Resin Bond Cutting Wheels

- Improve the cutting quality and efficiency:

- Cut faster

- Chip free cutting

- Good surface finish

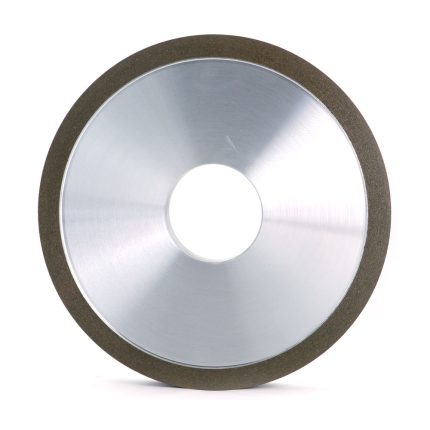

CBN Resin Bond Cutting Wheels

Resin bond CBN cutting wheels are typically for most tool and cutter grinder operations. In recent years, tool cutting machines have experienced new developments, merging automation and flexibility and ensuring increased precision and productivity. With the use of resin bond CBN cutting wheels for a variety of hardened cutting, the cost of cutting can significantly be reduced without excluding the production of better-quality cutting edges.

Users of resin bond CBN cutting wheels do enjoy how the tools can last much longer than conventional cutting wheels and how they need no or little conditioning, which offers less downtime for the maintenance of the wheels. Depending on applications, the savings in cutting costs with CBN wheels may be between 20 and 50 %, or even higher.

Moreover, resin bond CBN cutting wheels are ideal for several cutting workpieces, including cast iron, high-speed steel, nitriding stainless steel, stainless steel, hardened steel, tool steel, etc.

Note: Experts recommend CBN resin bond for cutting hard steels that go beyond Rc 50 at high speeds

Features of Resin Bond CBN Cutting Wheels

- Good self-sharpness

- Small grinding force

- No blocking

- High processing efficiency

Wrapping Up

In a nutshell, resin bond wheels are characterized by shorter life when compared with metal bond wheels. This is because of the adhesion between the bond and the grit, which is not so strong. Nonetheless, resin bond features better cutting capability as far as processing hard-to-grind materials (such as ceramics, cermets, etc.) are concerned.

It should be noted that the diamond and CBN abrasives for resin bond wheels are entirely different from those for metal bond wheels. Those for resin bond wheels are easy and irregular-shaped to microfracture. So, they are capable of creating novel cutting edges consistently.

Diamond CBN resin bond cutting wheels are widely used in several industries due to their fantastic features. These include highly efficient cutting performance perfect for wet and dry cutting operations, feature low heat generation, no burning, long tool life, cost-effective, and low roughness of workpiece surface.

With uttermost optimism, we believe that the details in this guide will immensely help you purchase high-quality tools designed to meet your professional needs as far as the cutting process is concerned.

You can also have More other customized cutting wheels from us.

[wpforms id=”4612″]

Reviews

There are no reviews yet.