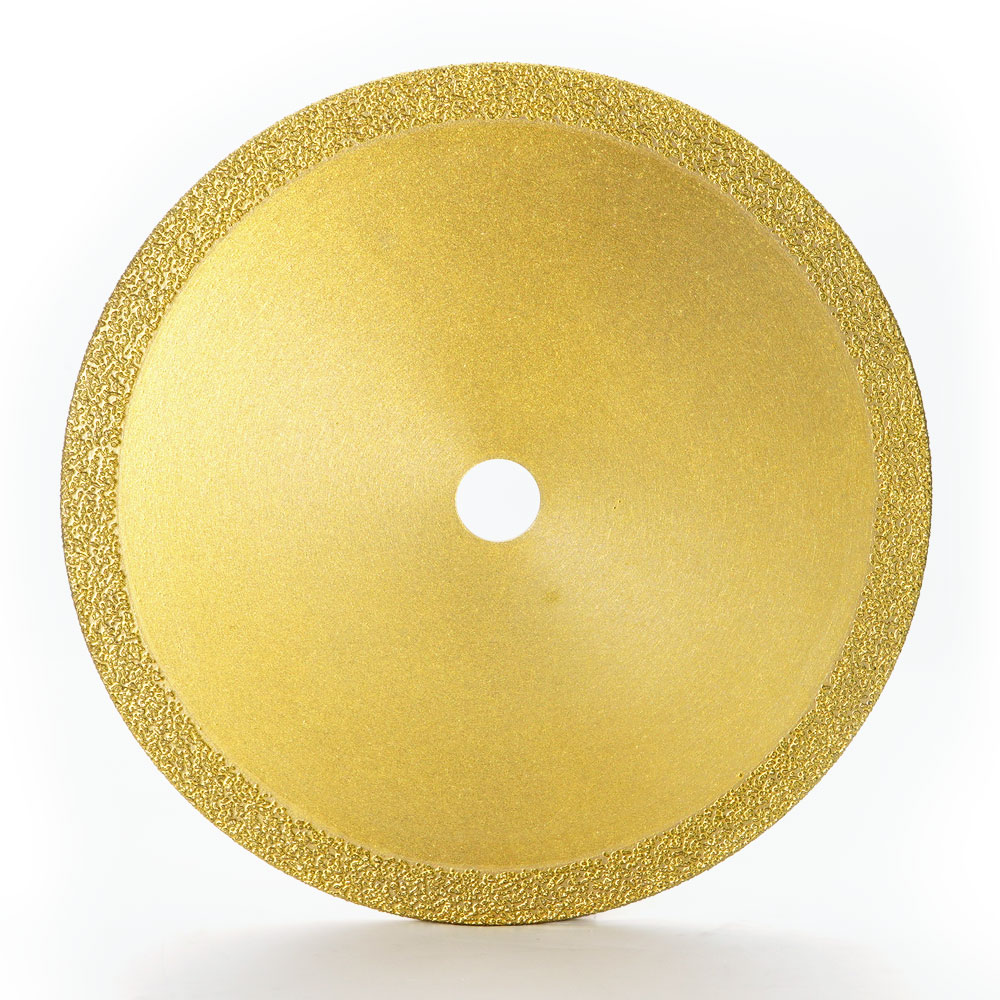

Brief Introduction of the brazed diamond cutting wheel

Brazed diamond cutting wheels are known for their high processing efficiency rate. They are ideal for complex surface machining. The unique process of their production, brazing, involves the melting and flowing of a certain kind of filler metal which should have a lower melting point than the ones adjoining. It allows the manufacture of some extraordinarily productive cutting wheels and abrasive discs that are much more coherent in function, ensure fast service by grinding at a rapid rate and show a longer lifespan than other similar wheels.

The brazed bond diamond wheels and discs are suitable for marble, glass, ceramic, concrete, vitrified brick metal castings, blended materials, and other wider range of processing fields. The closely combined wear resistance, compactness, and metallurgical properties of brazed diamond tools make them a perfect choice for any intense industrial use.

Features of brazed diamond cutting wheel

- Made with high-quality diamond grains, fire-resistant provides tremendous durability, and reliability with glass, ceramic, and stone.

- It can work well in both wet and dry conditions.

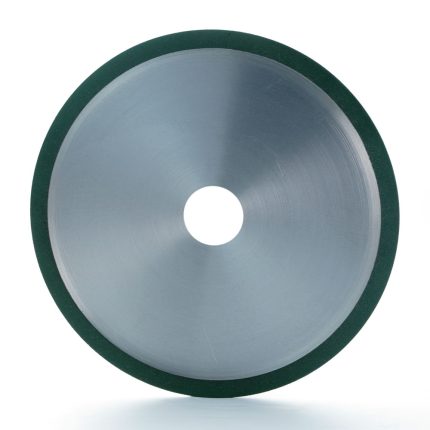

- Longer life than resin grinders, pollution-free, and little to no noise disturbance.

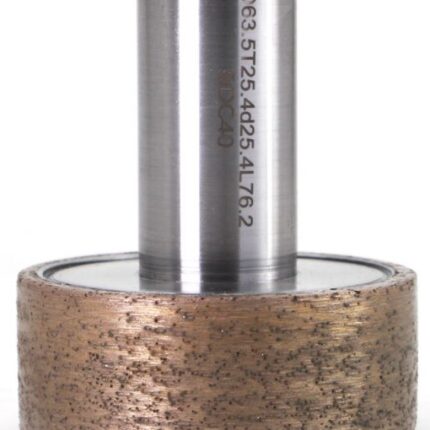

Detailed Description:

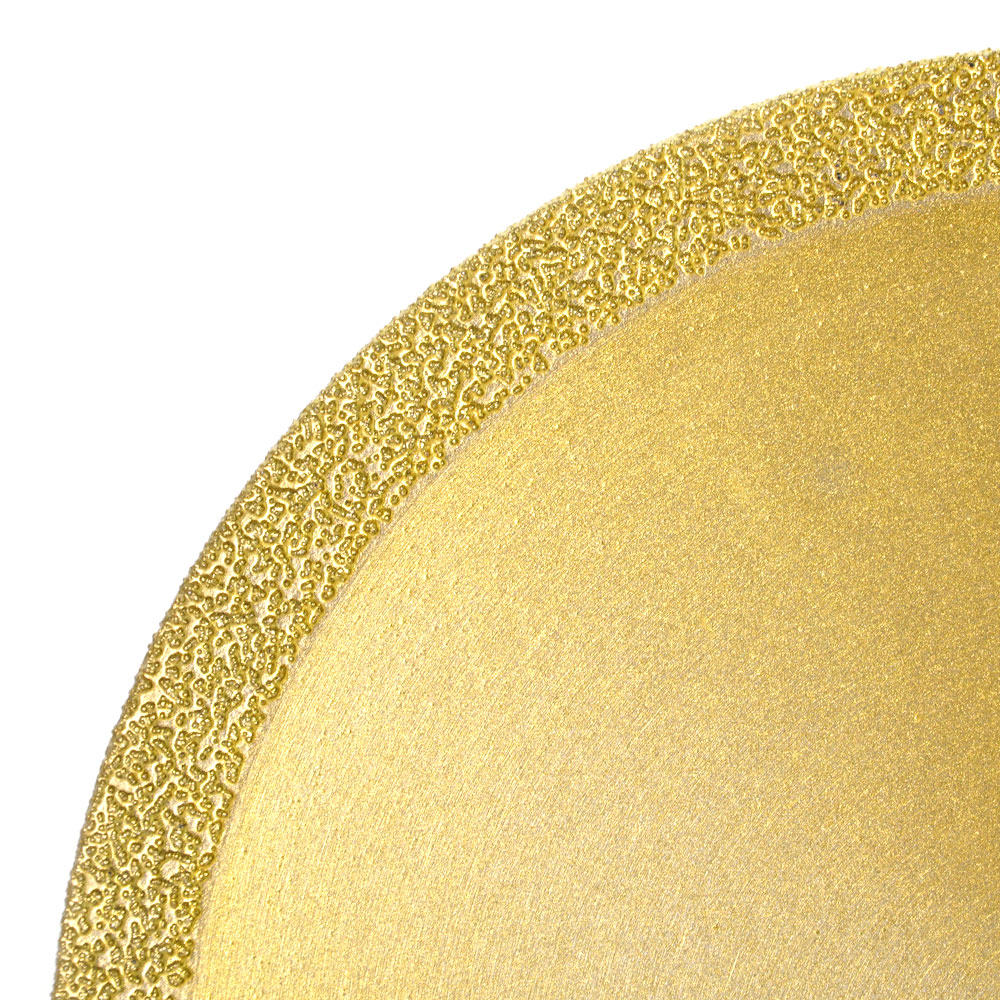

Made with new brazing technology, the cutting discs have about 70% exposure to diamond particles.

Super aggressive for incredibly hard materials.

Vacuum brazed continuous rim diamond cutting wheel made with bare diamond particles that make the cutter ideal for super hard materials.

They are widely used by firefighters around the world when a quickly forced entry is required into the buildings.

They are super light and can easily be carried anywhere.

It is a multi-purpose cutter that can work in both dry and wet environments. However, it is recommended to use water to cool it down when it is being used for an extended period for safe usage.

Brazed polishing discs have an advantage over traditional polishing discs as they have a 40 times longer service life. A one-time investment will serve a long duration.

Blade sharpness is 100% wear-resistant. Due to high diamond density, particles are firmly packed and not easily fall off.

Its strong blade ensures a smooth incision into any material.

It can evenly fix into any angle grinder or marble/ wood cutting machine.

The thickness makes the cutter stable, unbreakable, and balanced.

It is safe to use and environmentally friendly.

They show reduced dust residue and bad odors compared to the bonded abrasives.

No segment loss because of continuous rim shape.

Our controlled ERP system ensures guaranteed high performance.

More other customized cutting wheels are available, contact us.

[wpforms id=”4612″]

Reviews

There are no reviews yet.