Introduction of Diamond Silent Cutting Blade

The diamond silent cutting blade is one type of brazed diamond blade which are used for non-ferrous metal masonry and PVC. Diamond cutting wheels and diamond abrasive discs with the braze bond are known for their high processing efficiency rate. They are ideal for complex surface machining. The unique process of their production, brazing, involves the melting and flowing of a certain kind of filler metal which should have a lower melting point than the ones adjoining. It allows the manufacture of some extraordinarily productive cutting wheels and abrasive discs that are much more coherent in function, ensure fast service by grinding at a rapid rate and show a longer lifespan than other similar wheels.

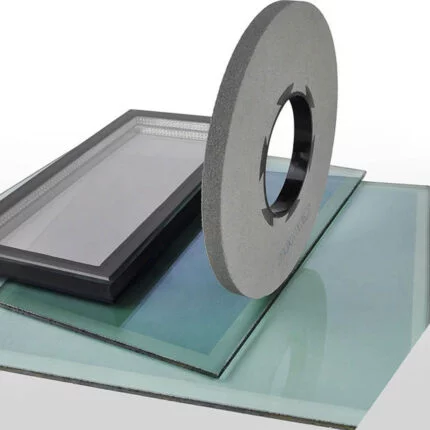

The diamond silent cutting blade is suitable for marble, glass, ceramic, concrete, vitrified brick metal castings, blended materials, and other wider range of processing fields. The closely combined wear resistance, compactness, and metallurgical properties of brazed diamond tools make them a perfect choice for any intense industrial use.

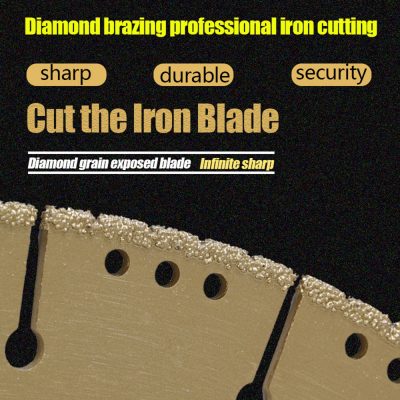

Diamond Silent Cutting Blade Features:

- segmented circular cutting blade, ideal for metal and iron.

- Manufactured with state-of-the-art vacuum brazing technology that ensures infinite sharpness.

- Silent cutting type for a smooth nuisance-free experience.

- Top-quality performance with abrasive material coated on either side.

- Works excellently in both wet and dry conditions.

Detailed Description:

The diamond silent cutting blade is manufactured with the process of vacuum brazing which ensures fewer sparks, less debris, and less odor.

It is suitable for remarkably hard materials.

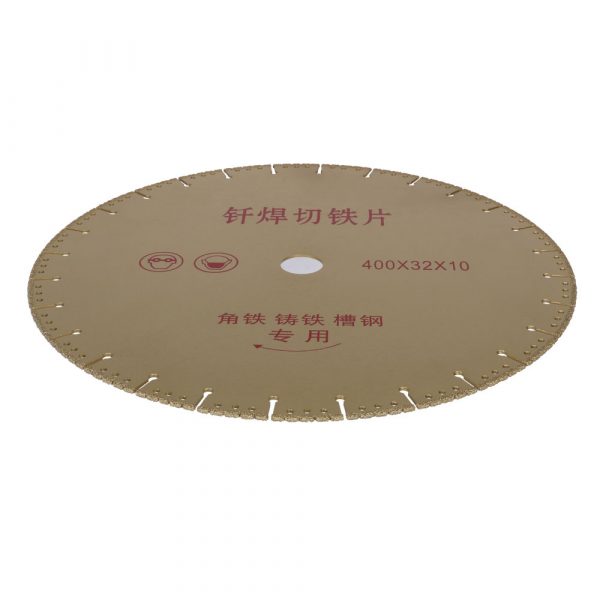

The cutting disc has a high concentration of diamond which is matrixed with a metal alloy and finished with a layer of sheen gold paint.

It has a diameter of 16 inches with roughly 28 teeth to cut through the material.

The item guarantees a long service life as it is wear-resistant and extremely hard to crack. However, ample safety is always recommended with gloves, masks, and goggles while handling.

Blade possesses a uniformly bright surface with coarse diamond grains spread evenly throughout.

It ensures high cutting accuracy, which lets it effortlessly cut any hard material into the desired shape.

The special teeth design helps in quick and easy piercing.

It has a wide application range: Angle iron, gray iron, ductile iron cast pipe, granite marble, aluminum, auto body panels, copper pipes, corrugated roofing, dry walls, fire door, rebar, stucco, rail, steel pipe, steel reinforcement, e.t.c.

Adjusts with all sorts of profile cutting machines, reciprocating saws, handheld grinders, and trim saws, e.t.c.

The brazed saw blade is ideal for working in wet and dry conditions. Little to no cooling lubricant is required in dry cutting.

A single blade is engineered to fulfill multiple purposes. A one-time investment will provide extended service.

It is firefighters, rescue teams, police, and demolition workers’ standard saw blade as it is perfect for emergency situations. It can cut into depth evenly, saving a lot of downtime.

It has a service life 100× better than other typical blades.

The blade comes nicely packed in a cardboard box.

Summary, the diamond silent cutting blade is one type of brazed diamond cutting blade that has excellent cutting ability for Angle iron, gray iron, ductile iron cast pipe, granite marble, aluminum, auto body panels, copper pipes, corrugated roofing, dry walls, fire door, rebar, stucco, rail, steel pipe, steel reinforcement, e.t.c. but fewer sparks, less debris, and less odor.

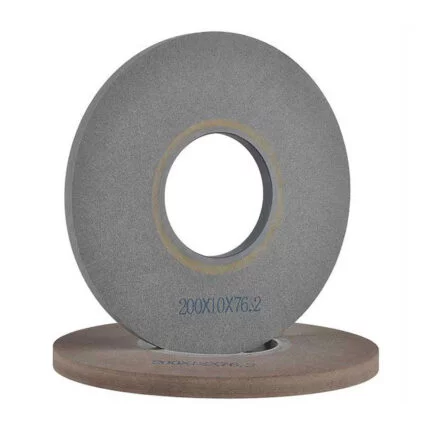

More customized grinding wheels are available, contact us.

[wpforms id=”4612″]

Reviews

There are no reviews yet.