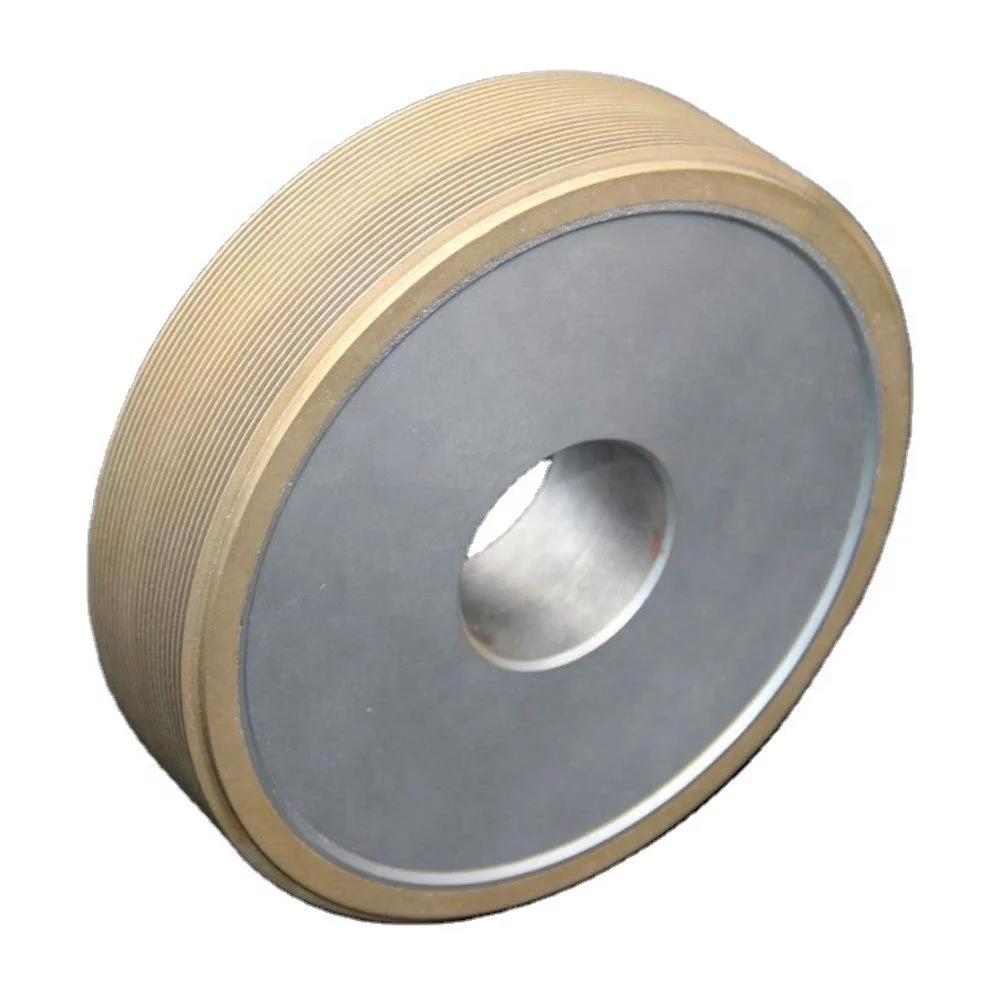

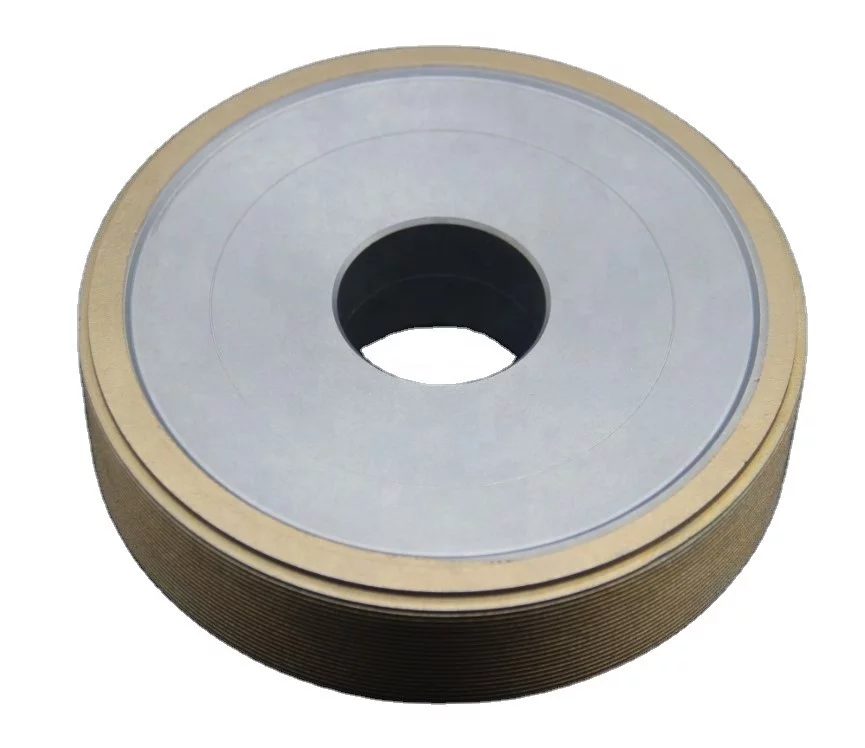

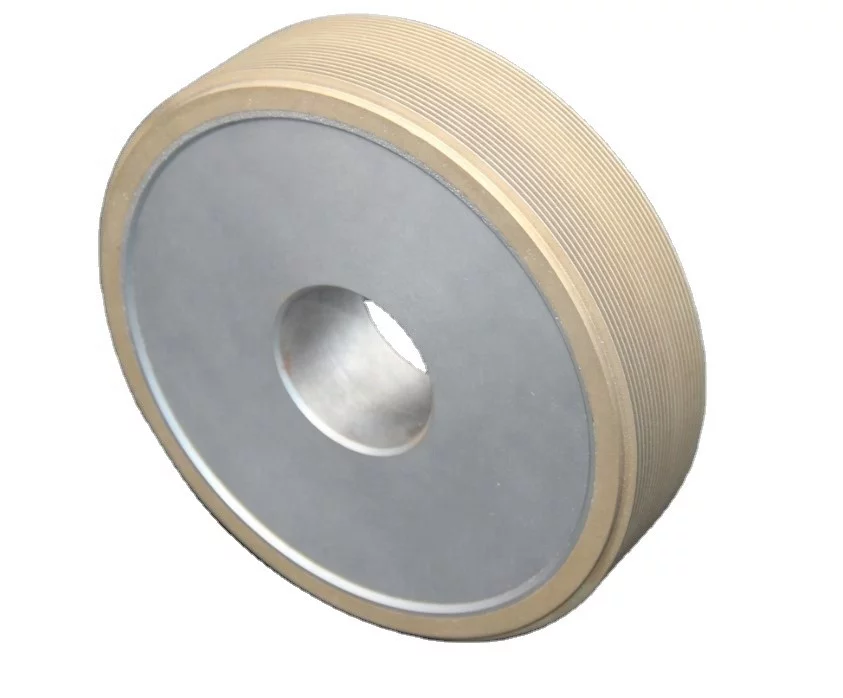

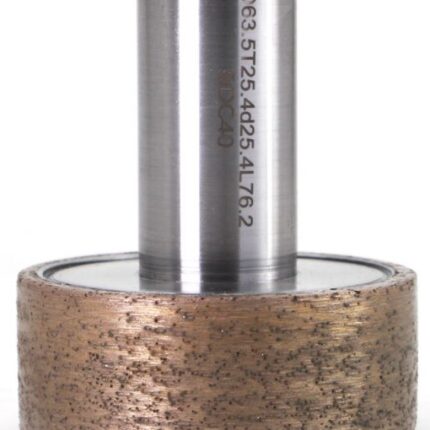

CBN Serration Grinding Wheels

CBN serration grinding wheels are used primarily for grinding, sharpening, and polishing. They are designed to shape the tooth form of a sharpening knife blade, hair clipper blade, and other blades of related tools.

Detailed Description of CBN Serration Grinding Wheels

CBN serration grinding wheels are made of high-grade body material (including iron/aluminum/stainless steel). They feature strong strength and prolonged service life. They are used in different workshops or industries to grind, sharpen, and polish blades of several tools. Some of the standard tools that CBN serration grinding wheels work effectively for include hair clipper blade, knife blade, etc.

Generally, the right serration grinding wheels are selected to grind scissors, knives, tongs, forceps, surgical instruments, and so on. Getting the most suitable and ultimately satisfying serration grinding wheel with the appropriate requirements for quality depends on the customer’s requirements. So, since we have garnered relevant experiences over the years, it would be great if you could get in touch with us for advice on the high-grade and affordable serration grinding wheel ideal for your process.

Application of Serration Grinding Wheels

There are three specific kinds of serration, including wavy serration, micro serration / pointed serration, and special serration.

Wavy serration

For a wavy serration, the grinding wheel is used on:

- Profile grinding of tongs and forceps

- Professional steak and hunting knives

- Household and table knives.

Micro serration

For a micro serration, the grinding wheel is used on:

- Barber’s scissors

- Household scissors

- Surgical instruments

Note: The micro toothing of the hairdressing scissors holds hair during cutting to avoid it from slipping away.

Special serration

For a special serration, the grinding wheel is used on:

- Machine knives

- Cutter Knives

Operation of Serration Grinding Wheels for knife blades and hair clipper blade

It’s important that grinding oil is provided during the grinding process. This is a rule that must be followed to ensure the cooling of the grinding wheel. After that, lead slowly and lightly the blade to the grinding wheel.

It’s crucial that you work in synchronism– meaning that the blade is held downwards as the grinding wheel runs in the direction of the operator. You should note that during grinding, the burr on the back side of the knife is minor and you can easily get rid of it with light polishing, or it can be removed with subsequent work with leather, felt, grinding, or contact wheel.

Specification of CBN Serration Grinding Wheels

Below is the specification of a CBN serration grinding wheel:

| Size | Body Material

|

Grit | Bond | Abrasive | Tooth profile

|

Shape |

| Customized | Iron/aluminum/stainless steel

|

180#-320#(D91-D46) | Metal | CBN | Flat/Serration

|

Flat shape |

More customized grinding wheels are available, contact us.

Error: Contact form not found.

Essential Features of CBN Serration Grinding Wheels

Check out below some of the unique features of the grinding wheels and why it’s regarded as the ideal option for knife blades, hair clipper blades, and other blades of related tools.

- Long Service Life: The grinding wheels are designed with high-quality material, which offers them ideal strength and long service life.

- Great Technique: The wheels are mainly used in serrated grinding.

- Excellent Usage: The wheels are designed for grinding, sharpening, and polishing.

- High performance: The wheels help keep the good shape of tools and offer perfect sharpness.

Summary

Serration grinding wheels are perfect tools for grinding scissors, knives, tongs, forceps, surgical instruments, and so on. They are strong wheels that feature high-quality performance and long service life. With the grinding wheels, you can grind, sharpen, and polish. They come in their peculiar specification with a wide range of applications.

More customized grinding wheels are available, contact us.

[wpforms id=”4612″]

Reviews

There are no reviews yet.