Understanding the Grinding Wheel Speed

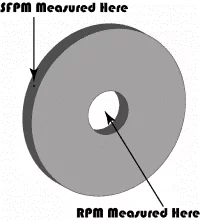

The speed of a grinding wheel is usually determined through two types of measurement, which are the Revolution per Minute (RPM) or through Surface feet per minute (SFPM) as a peripheral wheel. Also, we can ask some help from a professional machinist to determine the speed of the grinding wheel because there are many variables that affects the speed performance on various applications. To guide us in choosing the perfect operational speed for our grinding wheel, might as well read this grinding wheel speed chart guide.

Grinding Wheel Speed Chart Guide

Grinding Wheel Speed Chart based on SFPM

SFPM (Surface Feet Per Minute) is defined as the distance any abrasive grain on the cutting surface travels per minute.

The data below shows the measurement speed based on surface feet per minute. Here, the actual speed of the abrasive grit on the wheel is set by using the length of the path it takes while it revolves on the wheel’s axis. Here are some common speed ranges based on SFPM.

| TYPE | SPEEDS (SFPM) |

| Cutoff wheels | 9,000-16,000 |

| Cylindrical grinding | 5,000-12,000 |

| Disc grinding | 4,000-5,500 |

| Internal grinding | 4,000-12,000 |

| Portable grinding | 6,500-12,500 |

| Snagging | 5,000-12,500 |

| Surface grinding | 4,000 - 6,500 |

| Tool grinding | 5,000-6,000 |

| Weld grinding | 9,500-14,200 |

NOTE: The larger the wheels the faster the surface speed can be. There are available online converters for SFPM to RPM if you want to know the speed of the wheel based on RPM.

Grinding Wheel Speed Chart based on RPM

RPM (Revolutions Per Minute) is defined as the number of complete axes turns per minute.

The speed of the grinding wheel can also be determined through its RPM. There are three-speed ranges commonly known to which grinding wheels perform best – 5,500 to 6,500, 8,500, and 12,000 sfm. Most vitrified grinding wheels prefer to use 6,500 speed to ensure maximum wheel speed safety.

If you want to know the corresponding RPM of the grinding wheel from SFPM, you can try this formula.

Here’s a sample grinding wheel speed chart recommended for Diamond and CBN Grinding Wheels.

GRINDING WHEEL SPEED CHART

WHEEL DIAMETER | |||||||||||||||||

WHEEL SPEED | 1" | 2" | 3" | 4" | 5" | 6" | 7" | 8" | 9" | 10" | 12" | 14" | 16" | 18" | 20" | 24" | 30" |

SFPM | REQUIRED R.P.M. (Revolution per Minute) | ||||||||||||||||

2000 | 7600 | 3800 | 2500 | 1900 | 1500 | 1300 | 1100 | 950 | 850 | 760 | 640 | 550 | 480 | 425 | 380 | 320 | 255 |

2500 | 9500 | 4800 | 3200 | 2400 | 1900 | 1600 | 1350 | 1200 | 1050 | 950 | 790 | 680 | 600 | 530 | 480 | 400 | 320 |

3000 | 11500 | 5700 | 3800 | 2900 | 2300 | 1900 | 1600 | 1450 | 1270 | 1150 | 950 | 820 | 720 | 636 | 570 | 480 | 380 |

3500 | 13500 | 6700 | 4500 | 3350 | 2700 | 2200 | 1900 | 1670 | 1480 | 1330 | 1120 | 950 | 835 | 740 | 670 | 560 | 445 |

4000 | 15300 | 7600 | 5100 | 3800 | 3050 | 2500 | 2200 | 1900 | 1700 | 1530 | 1270 | 1090 | 955 | 850 | 760 | 640 | 510 |

4500 | 17200 | 8600 | 5700 | 4300 | 3400 | 2850 | 2450 | 2150 | 1900 | 1720 | 1430 | 1230 | 1070 | 955 | 860 | 715 | 570 |

5000 | 19000 | 9500 | 6400 | 4800 | 3800 | 3200 | 2700 | 2400 | 2120 | 1910 | 1590 | 1360 | 1190 | 1060 | 950 | 795 | 640 |

5500 | 21000 | 10500 | 7000 | 5300 | 4200 | 3500 | 3000 | 2600 | 2330 | 2010 | 1750 | 1500 | 1310 | 1170 | 1050 | 875 | 700 |

6000 | 23000 | 11200 | 7600 | 5700 | 4600 | 3800 | 3250 | 2850 | 2550 | 2290 | 1910 | 1630 | 1430 | 1270 | 1150 | 955 | 760 |

6500 | 24800 | 12400 | 8300 | 6200 | 4950 | 4100 | 3550 | 3100 | 2760 | 2480 | 2070 | 1770 | 1550 | 1380 | 1240 | 1030 | 830 |

7000 | 26800 | 13100 | 8900 | 6700 | 5300 | 4450 | 3800 | 3350 | 2970 | 2670 | 2230 | 1910 | 1670 | 1480 | 1340 | 1115 | 890 |

7500 | 28700 | 14300 | 9500 | 7150 | 5700 | 4800 | 4100 | 3600 | 3180 | 2860 | 2390 | 2050 | 1790 | 1590 | 1430 | 1190 | 955 |

8000 | 30500 | 15300 | 10200 | 7650 | 6100 | 5100 | 4350 | 3800 | 3390 | 3050 | 2550 | 2180 | 1910 | 1700 | 1530 | 1270 | 1020 |

9000 | 34500 | 17200 | 11500 | 8600 | 6900 | 5700 | 4900 | 4300 | 3820 | 3440 | 2860 | 2450 | 2150 | 1910 | 1720 | 1430 | 1150 |

10000 | 38200 | 19100 | 12700 | 9500 | 7600 | 6350 | 5450 | 4800 | 4240 | 3820 | 3180 | 2730 | 2400 | 2120 | 1910 | 1590 | 1270 |

11000 | 42000 | 21000 | 14000 | 10500 | 8400 | 7000 | 6000 | 5250 | 4670 | 4200 | 3500 | 3000 | 2620 | 2330 | 2010 | 1750 | 1400 |

12000 | 46000 | 23000 | 15300 | 11500 | 9200 | 7650 | 6550 | 5700 | 5090 | 4580 | 3820 | 3270 | 2860 | 2550 | 2290 | 1910 | 1530 |

RECOMMENDED SPEEDS FOR DIAMOND AND CBN GRINDING WHEELS

RESIN BOND | DRY | WET |

DIAMOND | 3000 to 4500 SFPM | 4500 to 6500 SFPM |

15 to 22 M/S | 22 to 32 M/S | |

CBN | 3000 to 6000 SFPM | 6000 to 7500 SFPM |

15 to 30 M/S | 30 to 37 M/S |

NOTE: The maximum speed for resin bond should not exceed 8,000 SFPM. Always follow the maximum safe wheel operating speed.

Importance of Understanding RPM and SFPM

Since grinding speeds are generally given in SFPM while machine speeds are given in RPM, having background knowledge about its characteristics is important in maintaining the life of the wheel. As the grinding wheel wears, the SFPM will certainly decrease. In order to maintain the quality features of your wheel, you have to maintain the SFPM. Likewise, to maintain the SFPM you have to increase the RPM.

Maximum Safe Operating Speed

For any grinding wheel, the maximum operating speed should be clearly visible on the grinding wheel. To ensure safety, always checked the marked operating speed on the grinding wheel to make sure that the spindle speed of the grinder does not exceed the maximum safe speed.

There are two ways how to check the maximum operating speed marked on the grinding wheel:

- Peripheral surface speed

- Rotational Speed

If you have smaller grinding wheels, specifically those below 80 mm in diameter, the maximum operating speed is given separately alongside the wheel. If you are looking for a high-speed grinding wheel, you can check the color-coded stripes marked across the center of the wheel.

Here are sample colors you can use for guidance:

- 50m/s – Blue

- 60m/s – Yellow

- 80m/s – Red

- 100m/s – Green

- 125m/s – Blue/Yellow

Note: If the grinding wheel appears “too hard”, the wheel speed can be decreased which slows the work speed ratio. This will certainly increase the cutting force per gain and will make the wheel become softer. Always remember, to never increase the grinding wheel speed above its rated maximum operating speed.

The speed of the grinding wheel should be correctly applied which is why it is very important to know the accurate speed using the grinding wheel speed chart. The maximum safe speed should be always observed to prevent damages, cracks, etc. that will definitely wear out the tool. May this blog guide you in choosing the precise speed for your grinding wheel. If you want to know more about abrasive grinding wheels, visit our website at agrindtool.com