Low-e coatings are usually applied directly on the glazing surface. They are designed to reduce the amount of infrared and ultra-violet light that can pass through glass without affecting the amount of transmitted visible light.

When glass absorbs light or heat energy, this absorption can be re-radiated by the glass surface or shifted away by moving air. The material’s ability to radiate energy is called emissivity.

Although Low-E coatings come with their benefits, there may be a need sometimes to remove them. This could be because of the limited performance of the adhesion between the Low-E coating and the spacer bar, such as butyl. This process is referred to as Low-E edge deletion. So, the main focus here is how to remove the Low-E coating.

How to Remove Low-E Coating: Low-E Coatings

Low-e coatings or low-emissivity coatings are thin, transparent, and metallic layers applied to the suspended or glass of an energy-efficient window. They can inhibit long-wave infrared heat and UV rays yet allow visible light to go through.

The coatings were designed purposely to counteract the high emissivity of the glass’s characteristics. So, they work effectively to ensure that where the heat is kept is well-controlled; outdoors (the summer) or indoors (the winter).

How to Remove Low-E Coating: How Does Low-E Coating Work?

Manufacturers use Low-E coating for a reason. When used, it is technically transparent to the short-wave solar energy from the sun, allowing it to go directly to the inner side. Nonetheless, the coating reflects a radiation heat that emerges from objects within a space (such as a room) back into it, hence significantly minimizing its loss.

There are double-glazed surfaces that can come with Low-E coatings. These surfaces feature almost similar insulating values to uncoated triple-glazed units. With only the Low-E coating, the R-value can be improved from R-2 to R-3.

How to Remove Low-E Coating: The Types of Low-E Coating and Their Manufacturing Processes

Low-e coatings are of two main types. These include:

- Passive Low-E coatings: They are made to maximize the solar heat gain into a building or home, creating a passive heating effect and minimizing reliance on artificial heating.

- Solar control Low-E coatings: These are made to minimize the amount of solar heat that travels into a building or home in order to make the building cooler and reduce air conditioning-related energy consumption.

There are two primary methods for the production of passive and solar Low-E coatings. These include:

- Pyrolytic/ hard coat process: This is a process that began to gain recognition in the early 70s. Here, the manufacturer applies the coating to the glass ribbon during its production on the float line. With this, the coating becomes fused to the glass surface while it’s still hot. This helps create a strong bond with excellent durability for glass processing during fabrication. Then the manufacturer proceeds to cut the glass into stock sheets of different sizes and get it ready to be shipped to fabricators.

- Magnetron Sputter Vacuum Deposition (MSVD)/ soft coat process: This is a process that emerged in the 80s and has over the years been continually refined. It involves applying the coating off-line in order to pre-cut glass in a vacuum chamber at room temperature.

Going back to the types above, it could be asserted that solar control Low-E coatings are associated with MSVD, and passive Low-E coatings are with the pyrolytic process due to the historical evolution of the respective technologies. Notwithstanding, this assertion may not totally be accurate. Besides, while manufacturers vary, performance varies from product to product as well.

How to Remove Low-E Coating: Where are Coatings Applied?

There are 4 main potential surfaces to which manufacturers can apply coatings in a standard double panel insulated glass.

- The first surface: This faces outdoors.

- The second and third surfaces: These are facing each other right inside the insulating glass unit. There is a peripheral spacer separating them, creating an insulating air space.

- The fourth surface: This faces the indoors.

It should be noted that the passive Low-E coatings will function well when on the third or fourth surface. This is because these last two surfaces are not too exposed to solar heat, unlike the first two surfaces. On the other side, solar control Low-E coatings will function well on the first two surfaces (typically the second surface because they thrive on the lite closest to the solar heat).

How to Remove Low-E Coating: The Performance Measures of Low-E Coatings

Manufacturers design Low-E coatings for various surfaces of insulating glass units. It doesn’t matter the type of Low-E coating; passive or solar control – each can help improve performance values. To measure how effective glass is with Low-E coatings, below are the properties that are used:

- U-Value: This refers to a window rating based on the level of heat loss it allows.

- Visible Light Transmittance (VLT): This refers to the measurement of the level of light that goes through a window.

- Solar Heat Gain Coefficient (SHGC): This refers to the incident solar radiation fraction got via a window by direct and inward transmission and absorption & re-radiation. The level of a window’s solar heat gain coefficient will determine the level of the transmitted solar heat. If it’s lower, then the transmitted solar heat will be less.

- Light to Solar Gain (LSG): This refers to the ratio between the window’s SHGC and its VLT rating.

Check below to see how the coatings measure up by reducing the degree of infrared and ultra-violet light that can go through glass without affecting the amount of transmitted visible light.

| Low-E, 1/4″ airspace, 1/4″ clear | U-Value | VLT | SHGC | LSG |

| Pyrolytic | 0.33 –0.37 | 54% –74% | 0.45 – 0.66 | 1.09 – 1.25 |

| Double-Silver MSVD (High VLT/Low Reflectance) | 0.29 –0.29 | 53% –70% | 0.28 –0.39 | 1.79 –1.98 |

| Triple-Silver MSVD (High VLT/Low Reflectance) | 0.28 – 0.29 | 61% | 0.27 –0.30 | 2.17 – 2.37 |

Note: Tint, size, and other great qualities are thought about when it comes to window designs. But the place of Low-E coatings cannot be underestimated. They determine what will be the general performance of the window and the lighting, total heating, and the cost of cooling a building.

How to Remove Low-E Coating: Low-E Coating Deletion

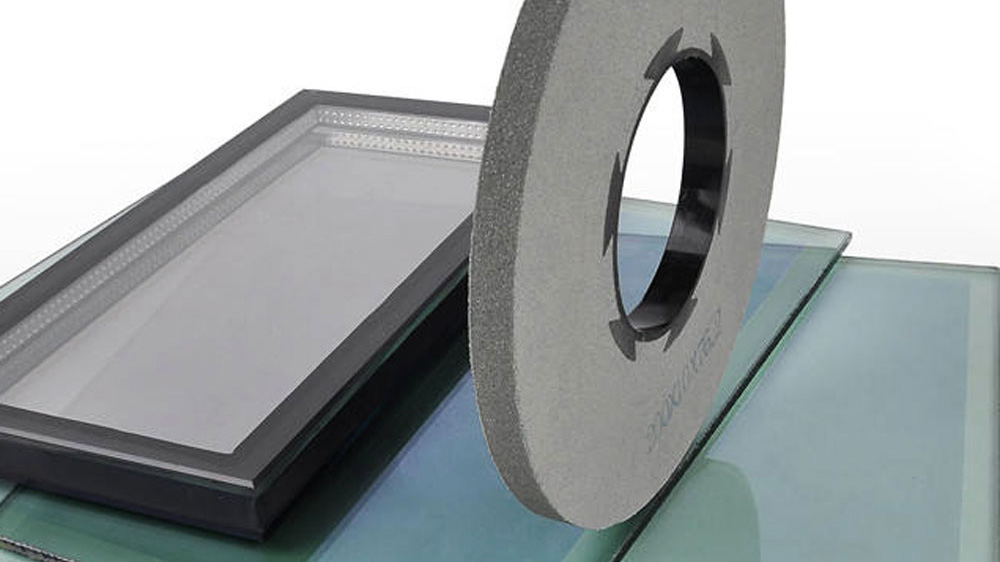

A Low-E coating deletion is a technical group of words used to describe the process of deleting with the use of an edge grinding technique that helps effectively remove every coating down to the glass surface.

Manufacturers make insulated glass units from two or multiple glass layers separated by a spacer and sealed with sealants. Edge deletion or the total removal of any moisture-sensitive coatings must be considered to make the sealants adhere to the glass. Precisely, deleting an edge involves removing a narrow strip of coating around the sheet of glass’s perimeter that has already been cut into size to ensure that the sealants bond to the glass directly.

How to Remove Low-E Coating: Why Remove the Low-E Coating Around the Edges of a Glass?

In building and architectural industries, Low-E coating glass is considered highly essential. This is because it’s eco-friendly and energy-saving. Technically, the coating is a highly fragile and thin film on the surface of the glass. So, the Low-E coating is often insulated with another piece of glass. The coating is usually positioned facing the interior part of double glazing. The space can be filled with inert gas or ordinary dry air. Either of these two wouldn’t lead to the corrosion of the Low-E coating. In fact, they help prevent the Low-E coating from becoming corroded.

Moreover, manufacturers use spacer bars (such as rubber, reinforced plastic, stainless steel, steel, or aluminum) to always separate the spacer between the two pieces of glass. Butyl, a synthetic rubber, is regarded as the preferred adhesive for sealing between glass and spacer bar because of its great moisture-proof.

Nonetheless, the adhesion between Low-E coating and butyl is limited in performance. Therefore, there is always a need to remove the Low-E coating around the glass edges (Low-E edge deletion). After the deletion process, the edges become exposed. So, butyl will have the chance to get in contact with the glass directly, helping the adhesion to perform impressively better.

How to Remove Low-E Coating: What are the Ways ?

Since it may be sometimes great to to know how to remove Low-E coating, there are several ways to get it done. The first significant method on how to remove Low-E coating is by using plain water to wet the surface of the glass thoroughly and using a clean cloth or sponge to rub the surface to get rid of the contaminants. Then use a clean, soft cloth or sponge to dry it. If this fails to provide the expected results, then repeat the same process but use a vinegar solution (10 –20%) in the water.

There are also several glass Low-E edge deletion machines and tools that operators can use for processing and removing the coating of the glass surface to its edge. Some of these include semi-automatic & fully automatic machines and handheld tools.

The fact remains that edge deletion of Low-E glass is a crucial part of making insulated glass units. To be done by hand, it could require some amount of effort and skill. By using manual grinding equipment to remove the edge, it can be challenging to ascertain that the process is consistent and complete. Besides, a lot of Low-E coatings feature reactive metal layers that are capable of affecting the sealant bond as time goes on when exposed to chemicals or moisture.

How to Remove Low-E Coating: Checking if the Edge is Removed

Even though they could be rear, you could easily see the signs of incomplete edge deletion. You can check in a simple way to ensure correct edge deletion by placing a piece of clear glass next to the edge-deleted area. It’s important that the clear glass is of similar thickness as the coated glass. It should be noted that if the edge is deleted correctly, then you will see the white paper having the same shade of color appearance via the deleted area as it is via the clear glass.

Conclusion

In the 21st century, glass remains one of the most versatile and popular building materials used. One of the reasons for this is how it’s constantly helping to improve thermal and solar performance. To achieve performance, passive and solar control Low-E coatings, which are the main types of Low-E coatings, can be used. Nonetheless, it may be a good idea sometimes to know how to remove Low-E coating to achieve the best performance. To know more, visit our website at agrindtool.com.