What is a Bench Grinder?

A bench grinder is a multi-purpose tool and very versatile in such a way that it can be used to work with various materials. Bench grinders are large grinding machines with abrasive wheels which is quite similar to a power sander on steroids. This grinding machine can be used for metal, wood, plastic, glass, and stone. To answer the question," can you grind glass with a bench grinder ?”, the answer to that is YES! A bench grinder can help you grind glass easily.

Can You Grind Glass with a Bench Grinder?

Bench grinders definitely make the grinding process for glass materials faster and easier. But before we answer the main question "can you grind glass with a bench grinder?", we have to know some basic knowledge about the grinding process, proper usage, and background experience shared by experts. This blog will guide you throughout the whole bench grinder application.

For beginners, it is natural to find the process difficult. To make it easier for you, you can follow these tips on how to grind glass with a bench grinder.

Usage Procedures in Bench Grinding Application

Typical glass materials like cast glass are quite unwieldy and bulky which often affects the posture and body parts of the machinist like the back, hands, and arms. This is why using a bench grinder is a very convenient idea. Here are the steps on how you can grind glass with a bench grinder.

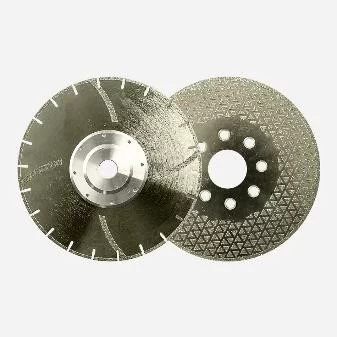

- STEP 1: Get an electroplated diamond disk that is made of glass. In some cases, resin diamond pads can be featured as it is very ideal for stone grinding. This will give you enough grit while doing the grinding application on glass materials even if you move from a finer grit to a midlevel grit. To ensure the durability of the glass material, try to use plated disks that are 3M since it is specially designed to work on glass surfaces.

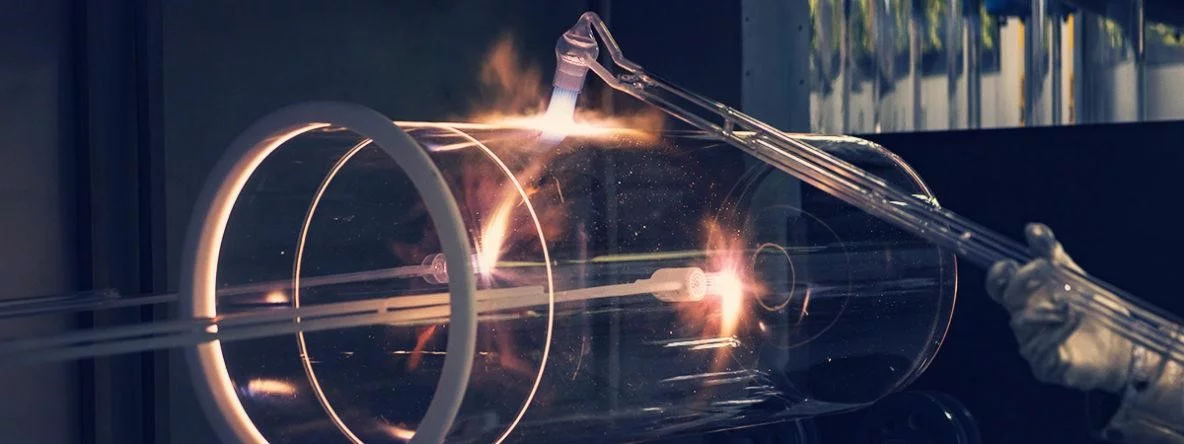

- STEP 2: After using the electroplated disk on your glass material, you will end up with a rough surface that needs to be polished. To smoothen the rough surface, you may apply the cerium or fire polishing method. This will make the plated diamond disk more electrostatically charged and is usually adhered to the back. Afterward, the adhesive part will be cured, which will lead to the standing of the diamond on the surface of the disk. Soon after, when it comes in contact with the glass, it will slowly bend. Due to this, the result will be an astonishing glass surface that is perfect for the polishing process.

- STEP 3: If you are looking for the best quality glass surface finishing, you can use a right-angle grinder. As you can see, the electroplated diamond disk provides an excellent job in glass surface finishing. But if you want to get a finer polishing process, you can use angle grinders. An example of it is the use of resin diamond smoothing disks which really fits finer polishing results.

Beginner’s Tips: How You Can Grind Glass With A Bench Grinder

Grinding using a bench grinder is one thing. But the process of how to use it properly, so it won’t get worn out and you can still do a lot more application aside from grinding, follow these amazing tips.

Grinding Rotation

To sharpen your glass efficiently and effectively, you have to grind against the observed wheel rotational direction. This will certainly achieve deeper cuts since you are pushing the glass pieces in opposite direction. Try to rotate the grinding wheel counter-clockwise if you want a sharper surface. But if you want a much-shallowed cut and additional control, push the glass against the grinding wheel while observing similar directions to the turning point.

Try some Dry Runs in a small piece

Before applying the grinder to your actual glass material, try it out on a small piece of glass. This will be a big help in learning about the texture, form, shape, structure, fragility of the glass material, and the mode of application. Train yourself by dry runs and practices. Don’t rush things out. Remember, experience is a good teacher.

Observe Proper Safety Protocols

To ensure safety throughout the grinding process, observe proper safety protocols like wearing safety goggles and gloves. The grinding procedure will create a lot of glass dust and glass chips. If you are not wearing any protective gear like safety glasses, it might go to your eyes and cause severe damage. It is also advised to wear safety gloves to prevent accidental wounds. You can also wear surgical tapes on your fingers to protect them from getting cut as you grind the glass.

Keep a Wet Sponge

A wet sponge on your side will keep the glass cool and humid throughout the process. Since grinding applications will make the glass material hot, it is recommended to keep a wet sponge with you during the actual grinding operation.

Fixed Chipped Glass Edge Problems

It is a common problem for bench grinding applications to have a chipped glass edge. When the shaft of the bench grinder is off-centered, then you have to replace the shaft. Don’t put too much pressure to avoid breaking the glass. Carefully check if there are worn-out bits. Do some replacement if there are major worn-out bits in your glass material.

So, can you grind glass with a bench grinder? There’s still a lot to catch up with bench grinder. To sum up, in this whole blog, choosing the right disk, observing proper safety protocol, and key experience will help you achieve your desired glass surface finish. To know more about bench grinders and other abrasive tools, you can visit our website at agrindtool.com or at forturetools.com.