What is a Grinder?

To deeply understand the answer to the question, "do you need a grinder for stained glass?", let us know first the concept of a glass grinder. A glass grinder is an electrical machine that grinds rough cut edges on the glass material to make it into smoother pieces free from jagged edges. This is also used for glass piece cut to fit the glass together to a one whole project design. This only proves that despite its high-rate expense, glass grinders are a necessary expenditure to consider as one of your art glass supplies.

If you have read our blog on how to grind stained glass, you will understand how beneficial and valuable it is in creating glass projects for decorative purposes. For now, let us discover the answer to this question, "Do you need a grinder for Stained Glass?".

Do You Need a Grinder for Stained Glass?

If you are an artist or a glass mechanist, getting a stained-glass grinder for your studio will help you create glass projects that will appear polished and professional. Getting the perfect shape of the stained glass is so satisfying and addicting that you would want to use this stainless grinder for every glass project you are working on.

But the question is, do you need a grinder for stained glass? Is it really that necessary?

Here are some reasons why you need a grinder for stained glass:

- Common stained glass grinders can operate at 3560 rpm with a 1/9 hp motor that grinds away glass materials faster than other grinding tools.

- It creates a very generous and polished work surface which is perfect for bigger glass projects. The larger the surface area leads to a more stable and safer operation of the stained glass grinder.

- It is a must for a grinder’s wheel to keep its humidity while performing the grinding operation. Likewise, stained glass grinders are compatible with various accessories like a coolant drain that keeps the wheel from being wet so there will be less friction between the wheel and the glass material.

- It also has a shield accessory that prevents glass particles and water from spraying everywhere. Aside from your safety glasses or goggles, this shield accessory will serve as your secondary barrier against possible sprayed particles or substances.

- Another important answer to the question, "do you need a grinder for stained glass?" is the concept of precision and accuracy element. Grinders are highly recommended for those glass pieces that should be ground with accuracy and precision. This is commonly done for fitting glass pieces into one whole designed project.

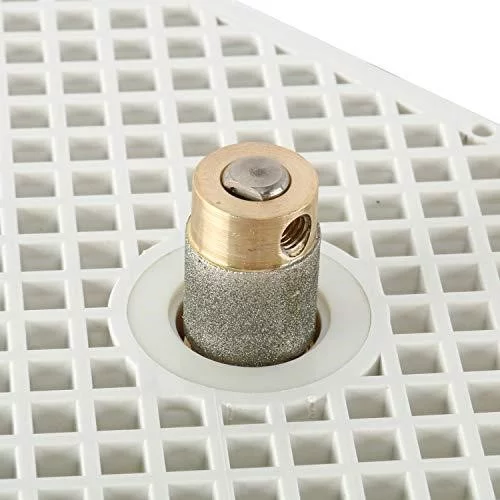

- Grinders have a diamond drill bit that helps slowly sand off the unwanted excess glass on your material which turns the pieces into a perfect puzzle piece that can be fit together.

- Stained glass grinders guarantee safety even in their utmost operation. It has this diamond bit located at the center which spins rapidly once you turned on its power. A wet sponge is usually attached to it during the grinding process to prevent glass dust or glass particles from going into the air.

- Compared to other grinding tools, stained glass grinders aren’t that loud and annoying to listen to. It smoothens the glass piece more perfectly than other grinders.

Things to Know About Stained Glass Grinder

If you want to purchase your own stained glass grinder and are still unsure where to start, here are some essential tips you need to know before getting the material on the market.

Force of the Grinder Bit

The force of the grinder bits should be well-coordinated before any grinding process. If a grinder is having enough power, it will be capable of maintaining the grinder bit’s optimum speed much better than a low-powered tool. The force of the grinder bit plays an important role in the whole grinding process since a well-maintained speed ensures fast and high-quality work.

Most grinders for stained glass used an amount of force ranging from 10-50.

Speed

Just like any other grinding tool, the speed is measured in “revolution per minute” or RPM. It is an important practice in choosing the best glass grinder. For a better-grinding result, always remember that higher-speed grinders with high force are able to perform grinding operations faster with very much hassle on the part of the machinist. With higher speeds, you can expect a smoother surface, edge finish, and more precise shaping.

Here are speed categories for stained glass grinders:

- Less than 3300 RPM: Also known as the “Entry-level grinders” where it is usually applied for very small pieces that require low grinding speed.

- Less than 3600 RPM: “Mid-range grinders” are applied for small and medium glass pieces that need moderate grinding speed.

- More than 3600 RPM: Known as “High-end grinders” is commonly used for all glassworks and heavy applications.

Size

Size does matter! The dimensions of your grinder affect your ability to operate or grind. For better grinding work, choose a perfectly fitted space for your desired material. If you’re grinding a large piece of glass, then it will be much better to choose a much larger space.

Accessories

The various grinder accessories add up to the amazing features of the grinding tool. One of the most used and known accessories of a glass grinder is its grinding bits. A higher-end bit might be quite expensive but guarantees a more satisfying result.

So, do you need a grinder for stained glass? The answer will depend on your preference and what you want to achieve. If you really want a high-quality ground-stained glass, then use a high-quality abrasive tool. In the end, achieving a perfect stained glass is our ultimate goal. Whether you find an expensive one or an ordinary type, the important thing is you are able to achieve your desired project after the grinding process. To know more about grinding tools, visit our website at agrindtool.com. or at forturetools.com.