Today Mrbrianzhao is gonna recommend two types of cutting wheels that can be used for lapidary production. One is metal bond diamond cutting wheels and another one is cold-pressed diamond cutting wheels.

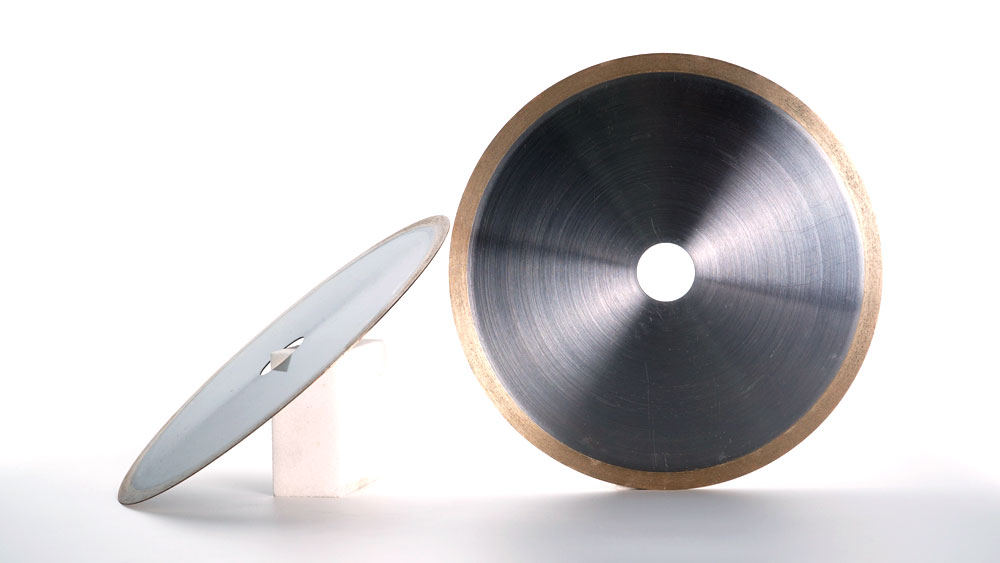

Metal bond diamond cutting wheel

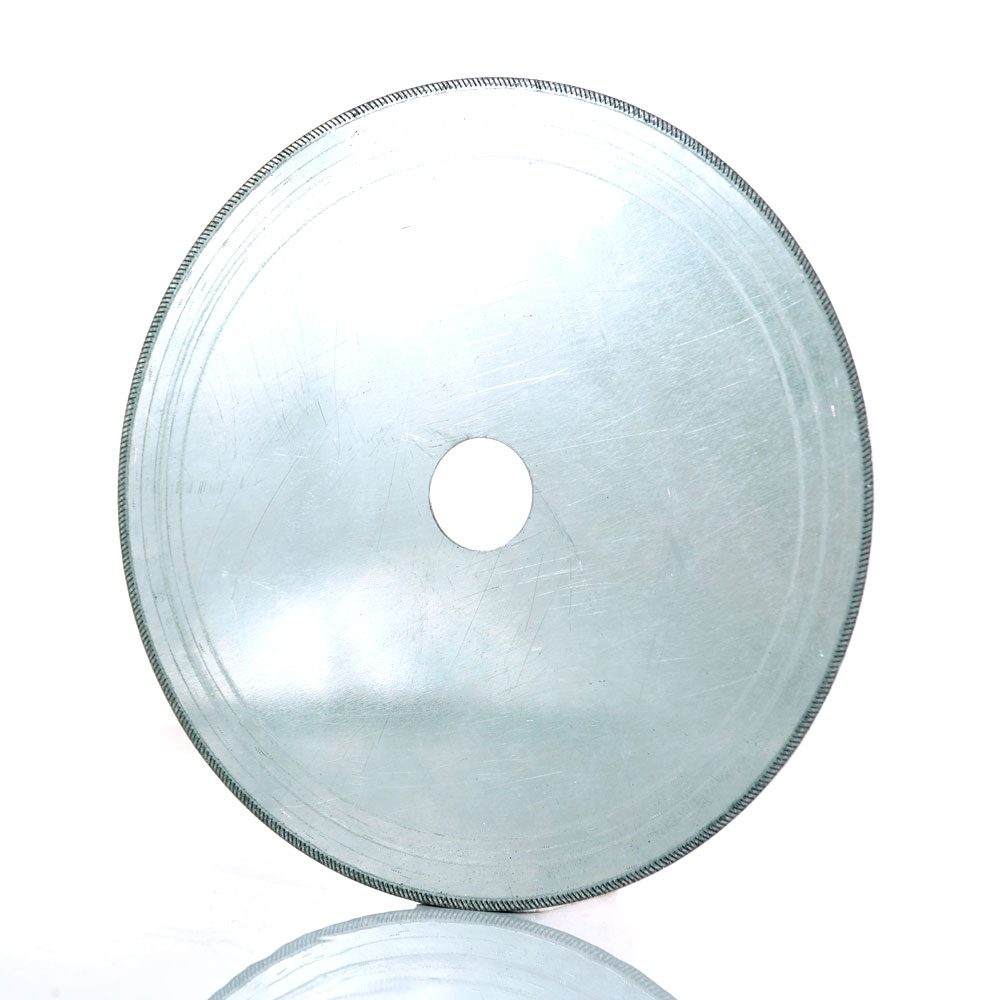

Cold pressed diamond cutting wheel

Cutting wheels differ from grinding wheels in their function and structure. In contrast to grinding wheels, which use an abrasive to grind material from workpieces from a shallow angle, cutting wheels usually make narrow, precise cuts at 90 degrees. In general, cutting wheels are thinner than grinding wheels – while they may not have the lateral strength required for side grinding, their thin profile makes them better for making clean, accurate cuts.

Metal bond Diamond Cutting Wheel Blade for Lapidary

A metal bond cutting wheel is a large, thin blade wheel used for precision cutting and grooving. It is ideal for processing precision molds because of its high blade thickness and run-out accuracy.

For lapidary cutting usage, metal bond diamond blades usually can be made into very thin thickness less than 1mm.

Metal bond Ultra-Thin Diamond Lapidary Cutting Disc Saw Blade for Jewelry Gems

Product description

The Ultra-Thin Diamond Lapidary Cutting Disc Saw Blade is the perfect cutting wheel for a lapidarist searching for a more precise cutting experience. These ultra-thin diamond lapidary saw blades are an excellent choice for those looking for long-term value or very thin kerfs.

Specifications

| Super thin diamond cut off wheel specification | ||||||

| Diameter | 50~60mm | 70~78mm | 80~110mm | 110~125mm | 127~200mm | Thickness Tolerrance |

| Thickness | 50~60mm | 70~78mm | 80~110mm | ±0.002 | ||

| 0.2mm | 50~60mm | 70~78mm | 80~110mm | 110~125mm | ±0.003 | |

| 0.3mm | 50~60mm | 70~78mm | 80~110mm | 110~125mm | 127~200mm | |

| 0.4mm | 50~60mm | 70~78mm | 80~110mm | 110~125mm | 127~200mm | |

| 0.5mm | 50~60mm | 70~78mm | 80~110mm | 110~125mm | 127~200mm | |

| 1mm | 50~60mm | 70~78mm | 80~110mm | 110~125mm | 127~200mm | |

| 1.5mm | 50~60mm | 70~78mm | 80~110mm | 110~125mm | 127~200mm | |

| 2mm | 50~60mm | 70~78mm | 80~110mm | 110~125mm | 127~200mm | |

| Arbor Hole | 6,8,9,10,12.7,16,25.4,31.75,40,41.275,50.8,76.2,69.875,88.9,114.3 | |||||

Features

- They are excellent for trimming small shapes into stones.

- They are best suited for turquoise, opal, glass, and stones in the 4-7 range on the Mohs hardness scale.

- They help achieve satisfactory cutting results and reduce unnecessary material consumption.

- These blades are manufactured by crimping synthetic diamonds directly into the edge of the saw blade.

- This thin lapidary saw blade offers a very good cost-effective option for those that want either very thin kerfs or plan on short-term use.

Applications

- Precision cutting of various gemstones, ceramics, quartz, glass, ferrite, etc.

Use Tips

Use water as a lubricant.

2. Cold Pressed Super Thin Lapidary Cutting Blade

Product Description

The Cold Pressed Super Thin lapidary cutting blade is made from high-quality cold-pressed diamonds and is thin, sharp, and unbreakable. This tool has been designed for cutting rare and valuable materials when waste must be kept to a minimum, as well as when the speed of cut is critical.

Specifications

| Diameter*Thickness | Bore | |

| 4" | φ100×0.5 | 20 |

| φ100×0.8 | 16/20 | |

| φ100×1.0 | 20 | |

| 6" | φ150×0.5 | 16/20/25 |

| φ150×0.8 | 16/20/25 | |

| 8" | φ200×0.8 | 16/25/25.4 |

| φ200×1.0 | 16/25/25.4 | |

| 10" | φ250×0.8 | 16/25/25.4 |

| φ250×1.0 | 16/25/25.4 | |

| φ250×1.2 | 25 | |

| φ250×1.5 | 25 | |

| 12" | φ300×0.8 | 25/25.4/32 |

| φ300×1.0 | 25/25.4/32 | |

| φ300×1.2 | 25/25.4/32 | |

| φ300×1.5 | 25/25.4/32 | |

| 14" | φ350×1.0 | 25/25.4/32 |

| φ350×1.2 | 25/25.4/32 | |

| φ350×1.5 | 25/25.4/32 | |

| 16" | φ400×1.0 | 25/25.4/32 |

| φ400×1.2 | 25/25.4/32 | |

| φ400×1.5 | 25/25.4/32 | |

| 18" | φ450×1.0 | 25/25.4/32 |

| φ450×1.2 | 25/25.4/32 | |

| φ450×1.5 | 25/25.4/32 | |

| 20" | φ500×1.2 | 25/25.4/32 |

| φ500×1.5 | 25/25.4/32 | |

| 22" | φ550×1.5 | 25/25.4/32 |

| φ550×2.0 | 25/25.4/32 | |

| 24" | φ600×1.5 | 25/25.4/32 |

| φ600×2.0 | 25/25.4/32 | |

| 26" | φ650×2.0 | 25/25.4/32 |

| 30" | φ750×2.0 | 32/36 |

| 32" | φ800×2.0 | 32/36 |

Features

- Long Life

- Sharp

- Super Thin

- Low loss of processed materials

- Premium Quality

- Wide Application (Suitable for Cutting Multiple Materials like glass, gems, crystals, agate, jade, and other non-metallic materials)

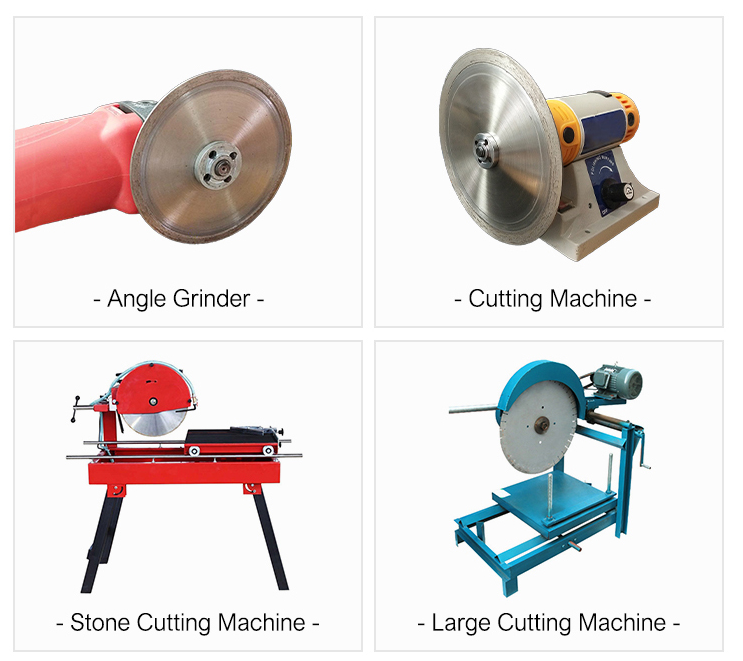

Application Machines

Use Tips

The direction of the saw blade’s markings must match that of the cutting machine’s rotation when installing it. Improper installation can easily lead to the inability to operate the saw.

Contact Mrbrianzhao

[wpforms id=”478″ title=”false” description=”false”]