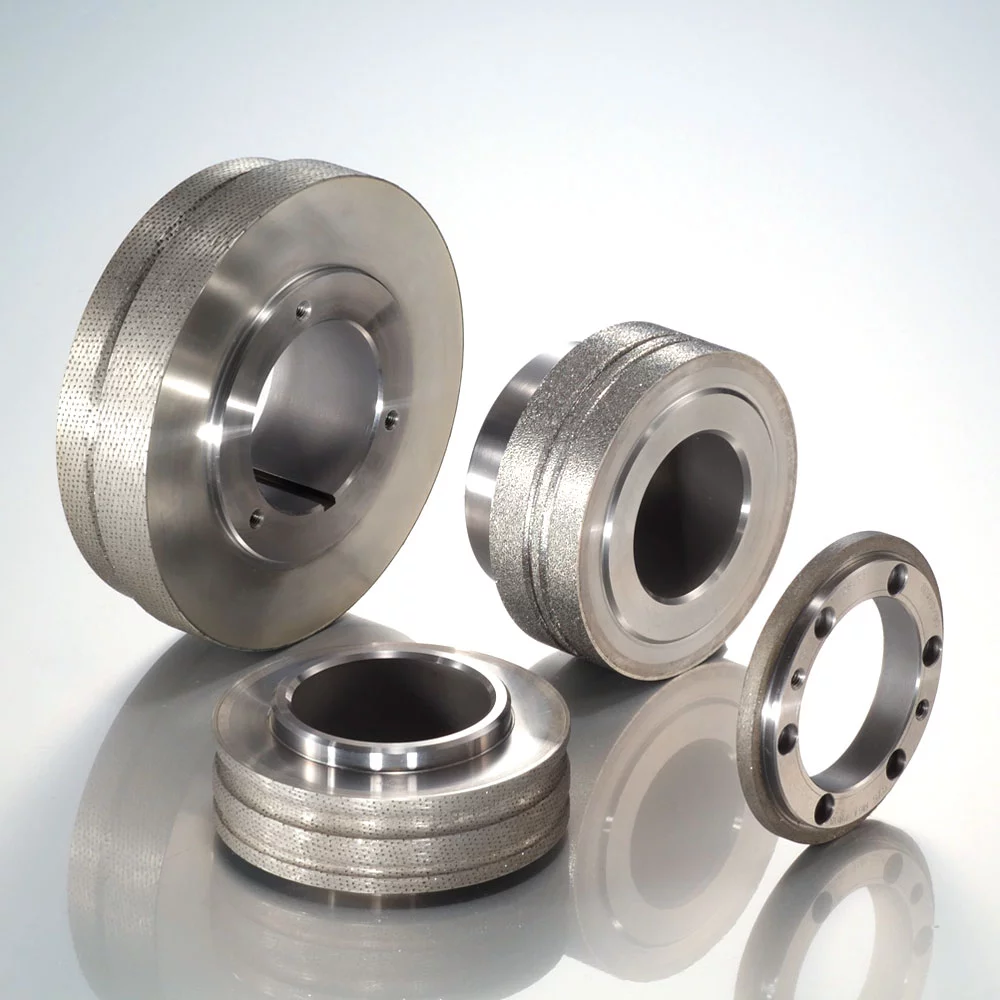

Sintered and Electroplated Diamond Rotary Dresser Wheel

Diamond Rotary Dressers are effective tools for forming and dressing conventional abrasive grinding wheels and CBN wheels. With its accurate and speedy form features for dressing, this diamond rotary dresser is highly applicable for the mass production of key parts while maintaining a high degree of accuracy. The diamond rotary dresser can be sintered or electroplated type. This high-precision diamond tool is used for oblique external grinding, cutting tools, injection parts, aircraft blades, and ballpoint dressing.

Selling Points/Features of Diamond Rotary Dresser:

- High Precision Tool. Suitable for dressing, forming, cutting tools, and grinding.

- Higher Dressing Consistency. This tool has good wear tolerance which makes it ideal for consistent dressing possible with minimal variation.

- High-quality Machine. Has improved precision for shaping wheels, with superior dimension accuracy. Plus, you can easily obtain the roughness and roundness of the material.

- Lower grinding cost. No worries about its maintenance cost. It has superior longevity when it comes to natural diamonds, which lessens the grinding cost.

- Designs can be customized according to the client’s requirements. It can be designed as a single product or assembly.

Product Specifications:

| Type | Manufacturing Method | Grit Distribution | Applicable Size | Profile | Dress Method |

| RZ | Electro-deposition | Random | #20-#140 | Complex Fine | Plunge |

| SZ | Regular | #16-#20 | Form | Plunge | |

| Z | Electroplating | Random | #30-#140 | Form | Plunge Traverse |

| SX | Sintering | Regular | #16-#20 | Form | Plunge Traverse |

| X | Sintering | Random | #30-#80 | Cup Straight | Traverse |

Range Specifications:

| Type | O.D. | Width |

| RZ | 50 – 230 | 200 |

| SZ | 50 – 230 | 250 |

| Z | 10 – 300 | 250 |

| SX | 20 – 180 | 150 |

| X | 20 – 300 | 150 |

Detailed Description of Diamond Rotary Dresser

A diamond rotary dresser is a high-precision tool for manufacturing machine parts, products, and other equipment. It became so popular with its effective and practical means for most high-tech industries in the modern world.

Two Types of Diamond Rotary Dresser

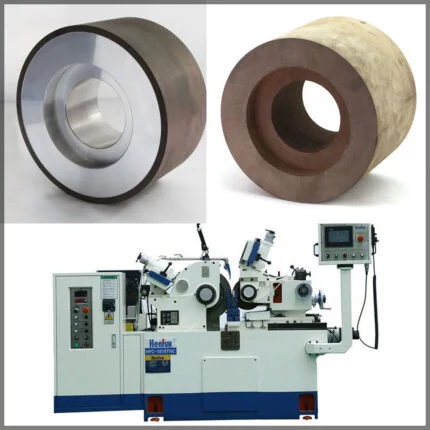

Sintered Diamond Rotary Dresser

Sintered diamond rotary dresser type is best for large quantities of high precision machining and suitable for all kinds of high hardness grinding wheels. Most diamond rotary dressers like the CNC track-type require sintering processing and manufacturing. This is because it must have the good abrasion resistance and strength with its tungsten carbide bond as skeleton material and cobalt metal as its bonding materials.

Application on Various Fields

Manufacturing industries like military, light industrial machinery, machine tools, machinery, aviation, bearings, military, and automotive uses this product. Here are various industrial fields where this diamond rotary dresser is being applied.

- Light Industry: refrigerator compressor, bicycle axle

- Hydraulic Industry: piston pump, connecting rod, blades, etc.

- Automotive Industry: valve body, valve parts, crankshaft, piston ring, transmission parts, engine components

- Machine tool Industry: gear processing, ball screw, guide rail

- Bearing Industry: bearing raceway, straight rail pair, cone-bearing, and spin bearing

- Tool Industry: drill bits, milling cutter, hob thread, slotted blade

Features of Sintered Diamond Rotary Dresser

Here’s why we sintered diamond rotary dresser is necessary for dressing, forming, and grinding

- It is one of the best diamond dressing tools which has high precision and efficiency.

- Widely used for gear grinding, textile machinery, aerospace, etc.

- Suitable for large quantities of high precision machining

- Suitable for all kinds of high hardness grinding wheel

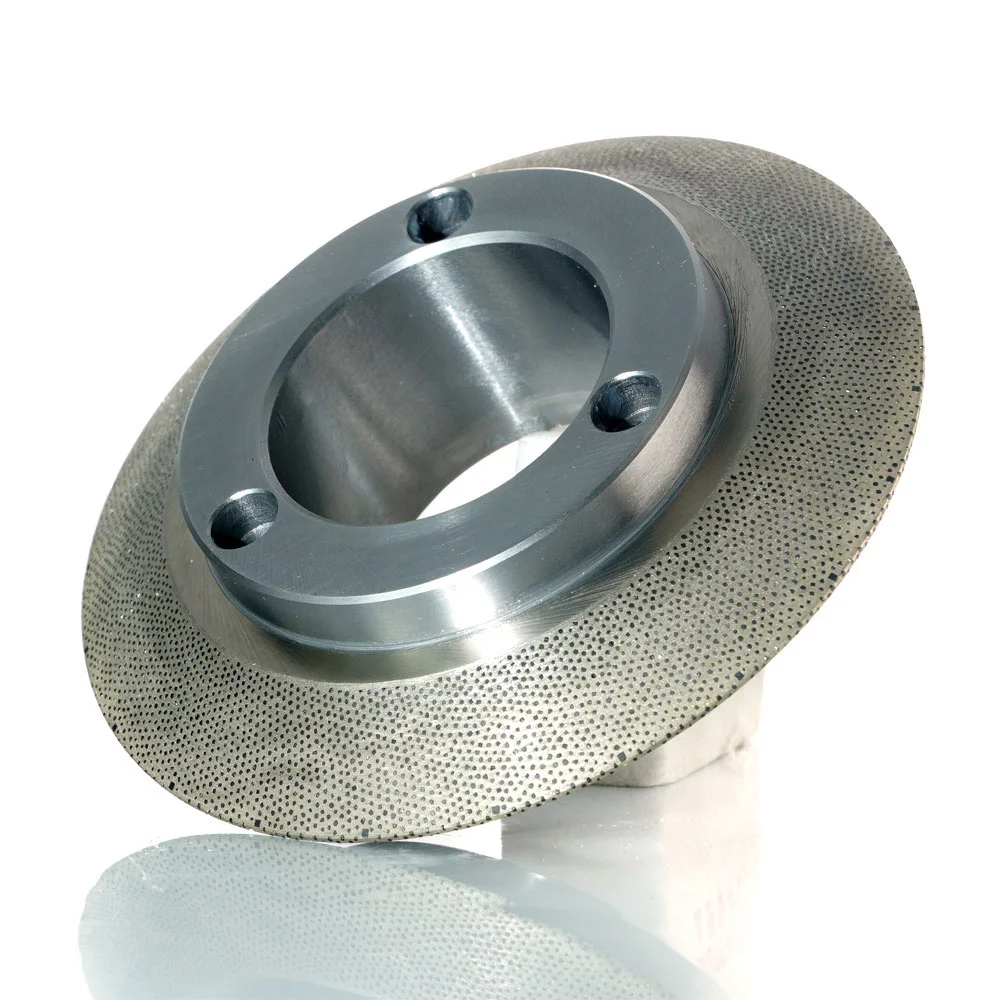

Electroplated Diamond Rotary Dresser

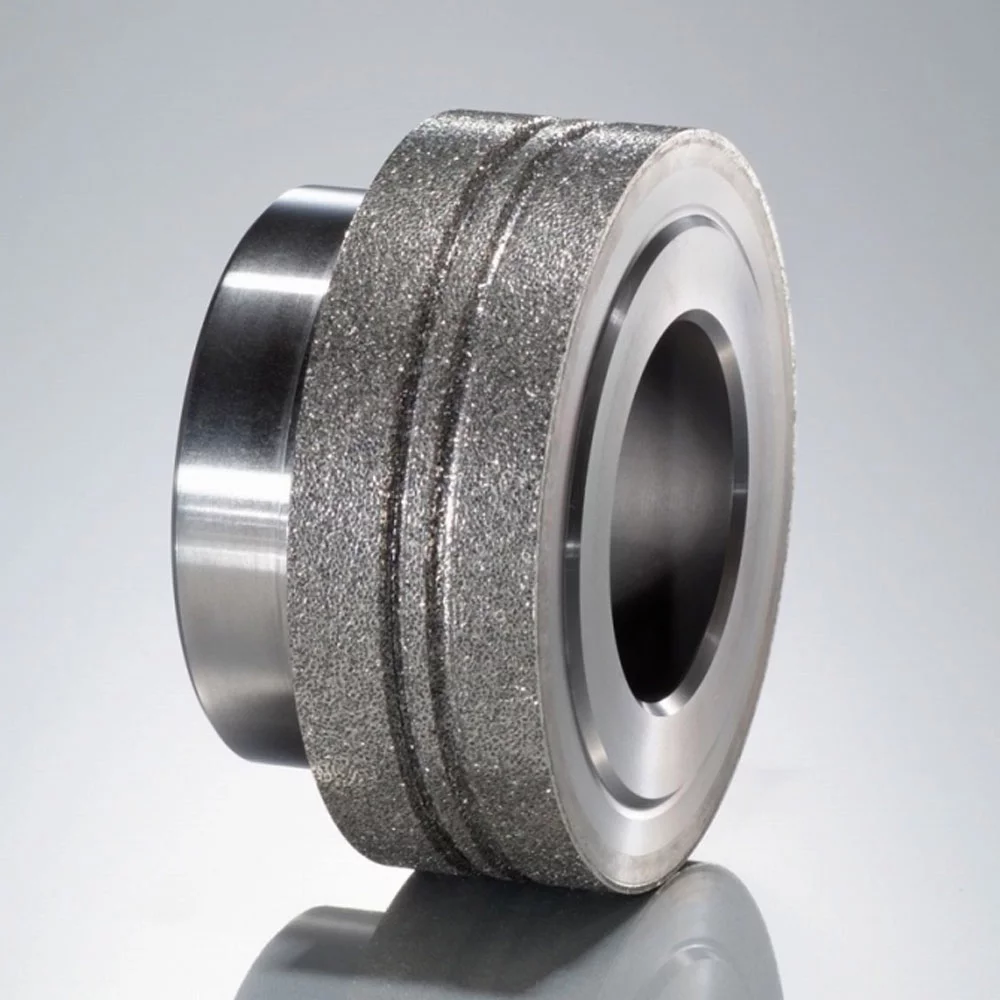

Electroplated diamond rotary dresser type consists of multiple thin layers of grains with diamond embedded through the electroplating process. Those thin layers of diamond with superior grain density provide lower dressing resistance which is ideal for narrow-axle grinding wheels and fine-grained wheels. It is made up of high-strength diamond, which makes the diamond content on the working surface of high quality and with less impurity.

Two Types of Electroplated Diamond Rotary Dresser

This tool can achieve high precision without even trimming methods. It is divided into two kinds: The outer plating method and the Inner plating method.

- Outer Plating Method. This is a simple, short cycle, and low-cost plating method used for electroplated diamond rotary dressers. Workers mainly use this method when the precision requirement is not that high. This is due to the inconsistency in the diamond particle diameter. The outer envelope can’t be consistent with the original contour of the matrix and you may find difficulty in achieving the same rate of mental disposition in all parts of the matrix.

- Inner Plating Method. This type has high strength and high purity diamond abrasive grains. This absolutely makes the diamond is much higher quality and with very few impurities. You can easily have high precision without the dressing process. With this, there are many diamond particles on the working surface and more cutting edges in dressing which gives you less wear and better shape accuracy.

Applications

- It is mainly used for inner-surface grinders with vitrified CBN wheels.

- Machine tools Industry: rails, general bearings, screws, valve parts

Features of Electroplated Diamond Rotary Dresser

Here are some features of why an Electroplated diamond dresser is both necessary and beneficial.

- The precision requirement is not high and is easy to use

- High performance, tool efficiency, high accuracy, and low cost in maintenance features.

- Contributed a lot to the development of the mechanical industry (automobile, machinery, aerospace, and many more)

Detailed Application of Diamond Rotary Dresser

Here are some popular applications of Diamond Rotary Dresser in various fields of machinery and technology.

- Oblique external grinding. Diamond Rotary Dresser for profiling wheels is used for oblique external grinding. Its diamond grains are positioned for dressing and profiling of various wheels like the vitrified wheels and resin bond type. They are used for various stages of grinding wheel with a high precision binder.

- Cutting Tools. Diamond rotary dresser can be applied as cutting tools with the diamond profiling wheels diamond grit is being impregnated. This is intended for dressing vitrified bonded wheels and resin bond wheels.

- Injection Parts. The application is made by reverse method or making a negative electrolytic plating of high accuracy which is suited for high precision vitrified bonded wheels.

- Aircraft blade. This rotary dresser is also applied in the aerospace industry where profiling of grinding or cutting is passed into the mass turbine blades. A high-precision negative electroplated is applied for wheel profiling.

- Ball joint. An angle grinder is used to allow straightening the concave and convex radius of the wheel while putting high accuracy into the binder. A diamond roll is made with diamond grains and is applied for wheel dressing and profiling.

- Forming gear grinding machine. A diamond rotary dresser is used for forming gear grinding machines. It is tested to be highly reliable and has good retention of arc to avoid frequent modification.

Factors to consider when choosing Diamond Rotary Dresser

- Machined Workpiece. Be oriented with the workpiece name, material, heat treatment state, technical requirements, machining allowance (radial, axial, etc.), and its machining accuracy.

- Machine tool. Try to learn about the machine’s tool manufacturer, machine model, machine type (external cylindrical grinding, surface grinding, crankshaft grinding, bearing grinding, etc.). It is also important to familiarize yourself with its application objects, processing methods, and machining accuracy.

- Grinding wheel. Consider the size of your grinding wheel particularly its outer diameter, thickness, and bore diameter. Check its technical parameters also like the abrasive, grain size, hardness, bond, linear velocity, etc.

- Driving equipment. If you are using driving equipment along the process, then focus on the size of the diamond rotary dresser, especially its max diameter, width, and bore diameter. If there is no driving equipment being used, then consider the dressing clamp, processing method, and size of the diamond rotary dresser.

- Grinding parameters. This factor includes the linear velocity of the grinding wheel, RPM of the workpiece, feed amount, feed speed, dressing cycle, grinding coolant, etc.

- Dressing position. The position of the dressing can be chosen according to the present situation and the client’s requirements.

Usage Tips for Diamond Rotary Dresser

Take note of these guide tips when you use a diamond rotary dresser for your work.

- Apply one grade coarser in the grain size of the diamond rotary dresser than the size of the grinding wheel.

- The rotary dresser’s steering and the grinding wheel should be opposite each other while maintaining their line speed. Keep a 0.3 – 0.6 ratio of the line speed between the diamond rotary dresser and the grinding wheel. Also, the rotation speed should avoid multiple relations in the process.

- During the dressing process, by all means, you must avoid impact between the diamond rotary dresser and the grinding wheel. The single dressing quantity can be rough or fine. When doing the finishing process, adjust the model of the grinding wheel to 0.02 – 0.04 mm.

- Make sure to follow the policy when dressing the grinding wheel. Always remember, when you apply fast feeding, it cannot touch the grinding wheel. A slow feeding phase will make use of the required cutting speed feed. While light repair policy is done with withdrawal movement to ensure the service life of the tool.

Diamond Rotary dresser is becoming more and more useful in industrial requirements with its high efficiency, high accuracy, and low-cost features. It contributed a wide range of improvements in various industries like automobile, aerospace, machinery, etc. Diamond rotary dressers are the best tool for truing and dressing conventional abrasive grinding wheels.

Reviews

There are no reviews yet.