Full Segmented Diamond Wheel for Glass Edging

A full segmented diamond wheel is the best tool used by several glass industries on glass edging machines. This machine works effectively for building glass, furniture glass, as well as similar glass sheets rough grinding. It’s a tool designed for beveling machines, straight-line/double edging machines, and so on.

Important Features of Full Segmented Diamond Wheel for Glass Edging

Check Out below some of the unique features of this wheel and why it’s regarded the best for glass edging:

- Super loaded: It is impressively a high efficient tool, with well-bonding material. Its cutting depth is deeper, with incredible rapid removing strength for uneven glass edges.

- Quality process: It is a tool designed to offer great sharpness. Besides, there won’t be any edge chipping during the grinding process.

- Perfect radiance: It ensures that glass edges are smooth, with no lines after the grinding process. Users will enjoy its slow consumption and great elasticity.

- Long service life: It is well-known for its durability. It has a long work-life, which helps minimize how often the grinding wheel can be replaced.

- Low heat creation: It is a tool that creates low heat with less burnish, producing a bright polishing effect.

Detailed Description of Full Segmented Diamond Wheel for Glass Edging

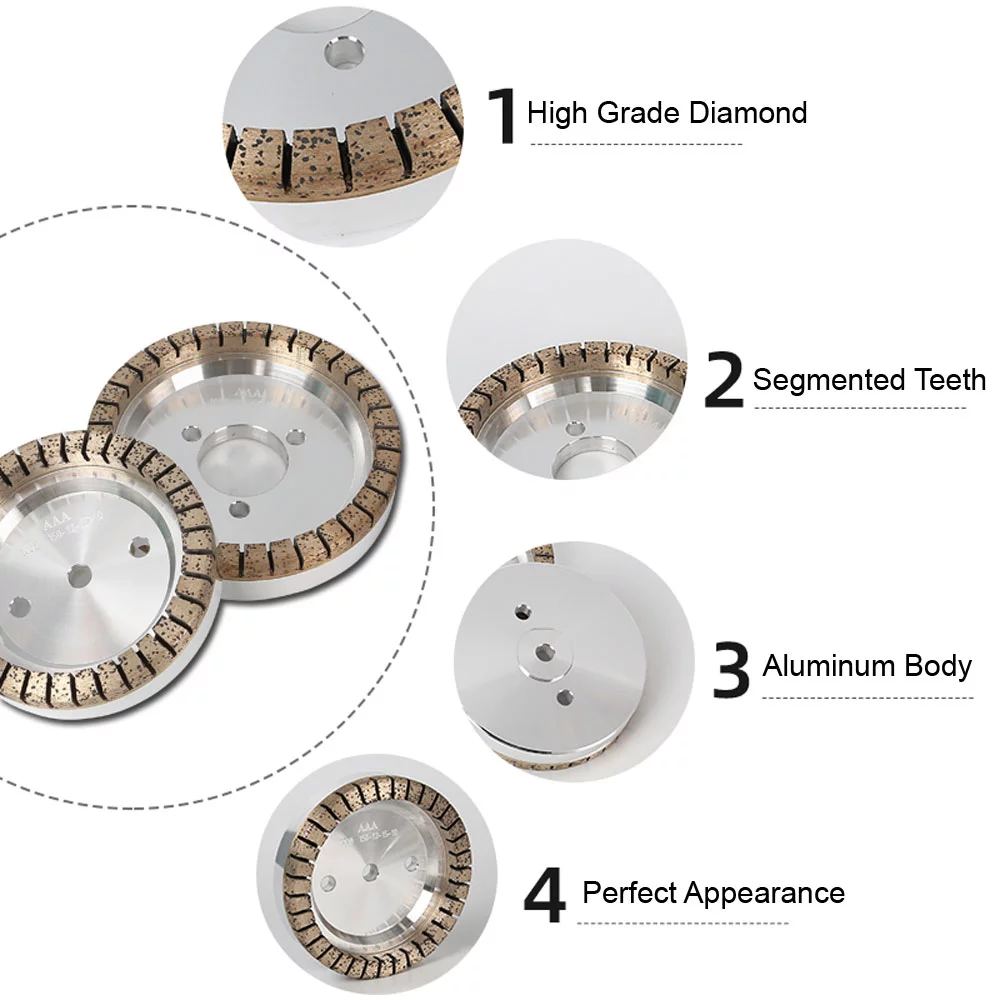

The full segmented diamond wheel is designed with premium metal powder and synthetic (self-produced) diamond grits, sintered in high pressure and temperature.

It’s characterized by high-quality diamonds perfect for glass processing. The tool’s appearance is close to a jagged edge, with a design that is capable of improving the cutting force of the wheel and contributing to the work of excretion and water.

A full segmented diamond wheel can reduce the temperature in working and effectively protect the glass from burns or explosions that could be caused by heat.

Generally, there are three kinds of diamond abrasive wheels. They are full rim, half segmented, and full segmented. The suitable specification and grit are selected based on the actual situation.

Full segmented diamond wheel for glass edging is applied to 3 to 25mm thickness glass. The adjustment of the pressure and the transport speed of the machine will be according to the thickness of the glass.

More so, the adjustment of the angle and position between the abrasive wheel and glass will depend on the size of the glass. During the grinding process, you should ensure that the glass maintains its straight trajectory and prevent it from jittery or slipping.

Application of Full Segmented Diamond Wheel for Glass Edging

Full segmented diamond wheel for glass edging has a very wide range of applications. It’s effectively used for horizontal/vertical single and double-edging machines, beveling machines, and shape edging machines. Its application covers a variety of domestic and imported glass edging machines.

The tools are typically applied when there is a need to process construction glass, electronics glass, furniture glass, bathroom glass, appliances glass, and so on. Some of the common use of this glass is for glass tables, architectural glass doors and windows, indoor screen glass, glass rods, glass office partition wall, etc.

Full Segmented Diamond Wheel and Applicable Machine

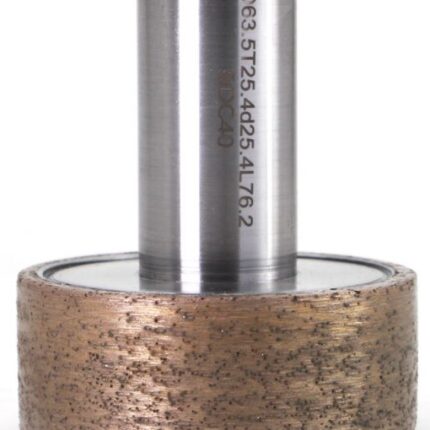

There is a glass straight edging machine and a glass double edging machine. A full segmented diamond wheel is usually installed on the double edging machine and straight edging machine’s 1# or 2# grinding motor. 80# or 100# is the commonly used diamond grit, with glass thickness that ranges from 3 to 30mm for grinding and up to 2880RPM as the maximum speed.

You are free to reach us in case you want professional guidance on the suitable grinding wheel you can choose and the installation process to adopt – we will be delighted to meet your need.

Moreover, a full segmented diamond wheel is ideal for every edging machine brand on the market, including ZXM, BAVELLONI, Schiatti Angelo, BOTTERO, Deway, and so on.

Full Segmented Diamond Wheel and Other Wheel Types

A full segmented diamond wheel can be used together with other types of wheel. Some of these include:

- Outer segmented diamond wheel

- Continuous diamond grinding wheel

- Resin diamond grinding wheel

- Diamond pencil edge grinding wheel

- 10S polishing wheel

- X5000 polishing wheel

- CE-3 polishing wheel

Benefits of Full Segmented Diamond Wheels

Below are some of the benefits users of full segmented diamond wheel for glass edging will enjoy:

- High sharpness

- High strength

- No chipping

- High thermal or heat resistance

Specification of Full Segmented Diamond Wheel for Glass Edging

Below is the specification of a full segmented diamond wheel for glass edging:

| Product Name | Full Segmented Diamond Wheels | ||||

| Use Machine | Size (mm) | ||||

|

Double Line Straight Line CNC |

Diameter | Width | Height | Aperture | Granularity |

| 175 | 15 | 10 | 12

13

30 |

80#- 140# |

|

| 150 | 15 | 10 | |||

| 150 | 10 | 10 | |||

| 150 | 10 | 10 | |||

| Process | Hot Press sintering | ||||

| Hole size | 12mm/22mm/50mm | ||||

| Grit | 80#/100#/140#/180#/240# | ||||

Tips for Using Full Segmented Diamond Wheel for Glass Edging

The following are attentions you must take seriously if you intend to use this wheel for glass edging:

- Ensure you check the wheel better to know if it’s intact or not (cracked or passivation) before using it.

- Ensure you install the wheel in the correct position and the right machine. You should know the appropriate grinding type (fine, medium, or coarse). Also, you should make sure the wheel passes the static balance test before using it.

- Use diamond wheel with water for grinding. This will help improve the efficiency of the work and extend the service life of the wheel.

- Ensure you choose the appropriate speed. Your grinding wheel may damage or injure the operator if its speed is too fast and its force is too much. Besides, the operator should put on safety protection.

- Ensure the grinding wheel is slightly trimmed if it blocks or is not sharp enough during the grinding process.

- Avoid leaving the diamond wheel in disorder, and don’t expose it to high temperatures.

Summary

A full segmented diamond wheel is an ideal tool for several glass industries. They are great for glass tables, architectural glass doors and windows, indoor screen glass, glass rods, glass office partition walls, etc. It comes with several fantastic features and benefits with different specifications (chosen as preferred by customers).

More customized grinding wheels are available, contact us.

[wpforms id=”4612″]

Reviews

There are no reviews yet.