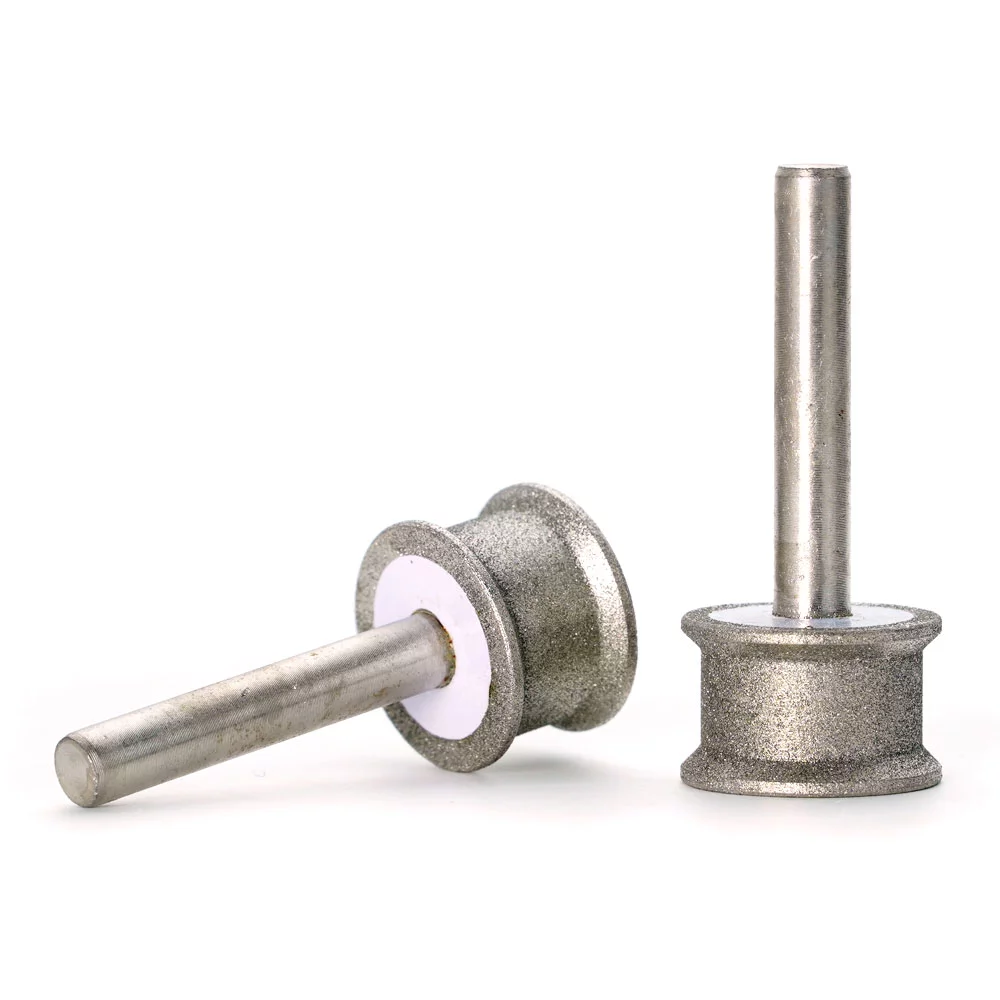

Edge Chamfering Wheel

Short Description:

Edge chamfering wheel is an abrasive tool that is intended for marble edge chamfering and polishing. This tool is also used for the precision machining of various materials like glass, jade, agate, beads, and other building materials. It can be applied on surface polishing on all kinds of glazed vitrified tiles. Its variety of advantages makes it a top-rank quality tool for glaze polishing abrasive works where it guarantees good sharpness, high gloss, no scratch mark, and longer service life.

Features of Edge Chamfering Wheel

- Fast grinding mechanism

- Excellent polishing works on marble and travertine edge profiles

- High production efficiency and low production cost

- High process speed and high glossiness on surfaces

- Uniform Thickness and consistent angle

Detailed Description of Edge Chamfering Wheel

Product Specification of Edge Chamfering Wheel

Edge chamfering wheel has various specifications available which depend on the client’s requirement and application. This tool can be bought on various grain sizes and dimensions. It can also be classified into resin-bond silicon carbide chamfering wheel, electroplated diamond mounted points edge chamfering wheel, metal bond diamond chamfering wheel, and many more.

Here is a popular product specification of the Edge Chamfering Wheel.

| Bond | Abrasive Grain | Grit | Head Diameter | Shank Diameter | Groove Thickness |

| Diamond | Electroplated | Rough 150# and Fine 400# | 20 mm | 6 mm | 3 mm, 4 mm, 5 mm, 6 mm, 8 mm, 10 mm, 12 mm |

| Resin Pressed | 500#, 800#, 1200#, 1500# | ||||

| Magnesite

|

24#, 36#, 46#, 60#, 80#, 120#, 180#, 220#, 240#, 280#, 320# | 90 mm/ 130 mm | |||

| Synthetic | 400#, 600#, 800#, 1000#, 1200# | 90 mm/ 130 mm |

Applications of Edge Chamfering Wheel

Edge chamfering wheel is applicable for chamfering and polishing marble edges. Grinding and precision machining of various materials is also the purpose of edge chamfering wheels. This chamfering wheel is applied for stone carving, jade carving, bone carving, egg decorating, glass carving, etc. In various industries, it is used for sculpturing, dressing, precision grinding, and internal grinding carbide in ceramic, glass, precious stones, alloy, and other abrasive materials.

Applicable Machines for Edge Chamfering Wheel

Edge chamfering wheel is very effective in restoration and re-polishing work which can be used together with different machines. It is suitable for automatic, semi-automatic, bevel edge polishing machines, multiple head machines, edge polishing machine, and arc edge polishing machine which has deep processing for edging and chamfering procedures. It can also be partnered on 10-14 head automatic edge polishing machines.

Tips on Using Edge Chamfering Wheel

This chamfering wheel is designed to make chamfering after squaring ceramic tiles. This ensures safety in transportation and utilization. The chamfering process removes sharp edges which helps in reducing possible cuts and accident incidence to people who handle metal pieces.

Here are some guides you can take note of when using the edge chamfering wheel.

- The electric drill speed must be 3600 rpm, while the bench drill and machine speed should be 6000 ~ 10000 rpm.

- Try to use water as a cooling lubricant while grinding. The water needs to be polished to achieve the best result.

- Using a diamond grinding wheel for precision machining of glass materials considering the glass thickness, jade, agate, beads, and other materials used for the building process.

- When using the wheel, check the thickness of the material. If it thickens to 8 mm, choose its corresponding groove at 8 mm.

- Make sure that the chamfering wheel is equipped with a snail lock pad that can easily be replaced. The snail lock pad provides better control for the user. This makes the grit easy to replace and reduces fatigue on the operator.

More customized mounted points are available, contact us.

[wpforms id=”4612″]

Reviews

There are no reviews yet.