Vitrified Mounted Points of Silicon Carbide Aluminum Oxide

Vitrified Mounted Points are one of the most popular types which are mainly used for the inner grinding of various metals and dressing mold. It can also be applied for finishing, deburring, polishing or honing, removal or roughing, cutting, surface cleaning, sharpening applications, and many more. Industries that require precision metal components usually used Vitrified Mounted Points.

Vitrified Mounted Points are the conventional type of mounting points which is sintered by a ceramic bond with a metal handle in the center. It comes in various shapes and dimensions. It is composed of abrasive grains, rubberized, and felt material. Mostly, it is made up of silicon carbide and aluminum oxide. It can be white aluminum oxide, brown aluminum oxide, or pink aluminum oxide. While silicon carbide mounted points can be black silicon carbide and green carbide mounted points. The bonds can be vitrified or resin type.

Features of Vitrified Mounted Points of Silicon Carbide Aluminum Oxide

- Wear resistance. Guarantees durable grinding mechanics and prolong the service of life.

- High grinding force. Highly efficient for metal grinding, dressing, and repairing.

- Strong handle fixed. Metal handled are highly attached and durable. You won’t worry about it getting affixed in the mounted head.

- Excellent balance control. Highly efficient and balanced which are control sensitive to use.

- Highly-efficient. Ideal for both small job shop applications and high-volume foundry operations. Provides cool cut, less burn, and higher metal removal rates.

Vitrified Mounted Points Product Specifications:

There are various product specifications of Vitrified Mounted Points in the market. Mostly, materials used for production are pink fused alumina (PA), Ruby grains, White fused alumina or white corundum (WA), Brown fused alumina or Brown aluminum oxide also known as Brown corundum (A), and green silicon carbide or green carborundum (GC). Here’s a standard specification for vitrified mounted points.

|

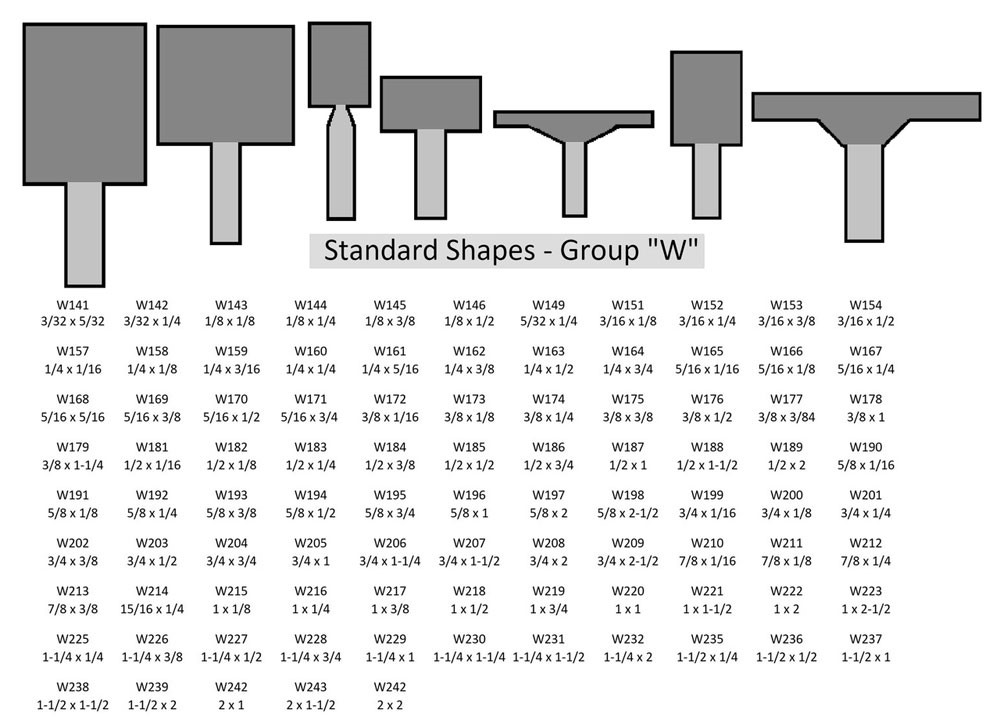

Explanation of the shape code system |

|

|

D = Mounted point outer diameter |

3 mm & 6 mm Shank diameter |

| T = Mounted point width |

40 mm standard Shank Lenght |

| Shape | DxT | Max RPM |

| W160 | 6×6 | 105000 |

| W162 | 6x 10 | 105000 |

| W163 | 6x 13 | 105000 |

| W164 | 6x 20 | 105000 |

| W167 | 8×6 | 78000 |

| W170 | 8×13 | 78000 |

| W174 | lOx 6 | 63000 |

| W175 | lOx 10 | 63000 |

| W176 | lOx 13 | 63000 |

| W177 | lOx 20 | 63000 |

| W179 | lOx 32 | 63000 |

| W183 | 13x 6 | 48500 |

| W184 | 13x 10 | 48500 |

| W185 | 13×13 | 48500 |

| W186 | 13x 20 | 48500 |

| W187 | 13×25 | 48500 |

| W188 | 13x 40 | 48500 |

| W192 | 16x 6 | 39400 |

| W193 | 16x 10 | 39400 |

| W194 | 16×13 | 39400 |

| W195 | 16x 20 | 39400 |

| W196 | 16x 25 | 39400 |

| W197 | 16x 50 | 39400 |

| W201 | 20x 6 | 31500 |

| W202 | 20x 10 | 31500 |

| W203 | 20x 13 | 31500 |

| W204 | 20x 20 | 31500 |

| W205 | 20x 25 | 31500 |

| W206 | 20x 32 | 31500 |

| W215 | 25 X 3.2 | 25200 |

| W216 | 2Sx 6 | 25200 |

| W217 | 2Sx 10 | 25200 |

| W218 | 25x 13 | 25200 |

| W219 | 2Sx 20 | 25200 |

| W220 | 25x 25 | 25200 |

| W222 | 2Sx 50 | 25200 |

| W225 | 32x 6 | 19700 |

| W226 | 32x 10 | 19700 |

| W227 | 32x 13 | 19700 |

| W235 | 40x 6 | 15700 |

| W236 | 40x 13 | 15700 |

| W237 | 40x 25 | 15700 |

| W238 | 38x 40 | 15700 |

For the shapes, here’s a brief description of choosing the perfect shape.

A – this is ideal for metal fabrication plants that have general maintenance applications.

B – This is ideal for light deburring of machined parts. It is also used for surface finishing or polishing molds and dies.

W – This is ideal for precision grinding especially for machined parts, molds, and dies, and involving medium to heavy stock removal.

Detailed Description about Vitrified Mounted Points

Vitrified Mounted Points are commonly found in foundry and precision engineering workshops. They are usually applied for deburring and cleaning up castings and machined components. It comes in various shapes like cylindrical or shaped with a shank diameter of 6 mm or 3 mm. It also comes in various abrasive types like pink aluminum oxide which is specialized for different types of steel, special mix grey, and pink aluminum oxide which is specialized for casting and foundries.

Silicon Carbide Vitrified Mounted Points

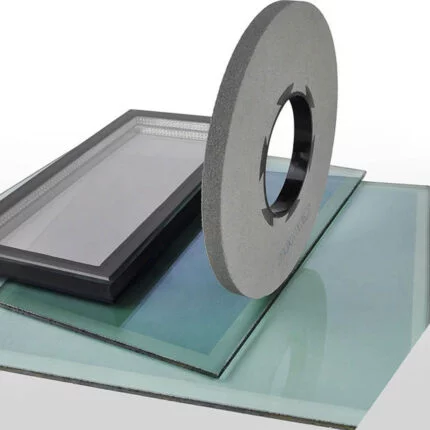

Silicon Carbide Vitrified Mounted Points are mainly used for cast iron, non-ferrous steel, non-metallic material, brittle and hard carbide, glass, gem, and stone grinding, cutting, and honing. It includes black silicon carbide and green silicon carbide mounted points.

1. Application or Usage of Silicon Carbide Vitrified Mounted Points

Mostly, vitrified mounted points are used for deburring molded parts, mold finishing, blending contours, internal grinding, offhand bench grinding, and tool or die applications. It comes from medium to hardpoints which offers a wide variety of uses.

- Surface Grinding. Used for cast iron workpiece. It also has high stock removal

- Edge Grinding. Also used for cast irons, and has burning-in with high form stability

- Cutting or Honing.

- Surface Finishing. Utilize the sharpness of silicon carbide to navigate a superior finish. Recommendable for finishing since it is very forgiving. It can create a remarkably consistent finish.

2. Features of Silicon Carbide Vitrified Mounted Points

- Silicon Carbide Vitrified Mounted Points have a fast-cutting abrasive performance which is commonly used for non-ferrous metals and applied in low-pressure conditions.

- It has sharpers and a harder grain type compared to aluminum oxide.

- Best for finishing and can easily be applied for cutting glass, plastic, and metal materials which are under light pressure due to their razor-sharp grains.

Aluminum Oxide Vitrified Mounted Points

![]()

Aluminum oxide materials are frequently used in the industry due to their application on various materials like bare wood, painted surfaces, and metal. It is much more durable compared to silicon carbide materials. Various forms of aluminum oxide vitrified mounted points include brown aluminum oxide and pink and white aluminum oxide.

1. Form of Aluminum Oxide Vitrified Mounted Points

- Brown Aluminum Oxide. This is the most common form of aluminum oxide vitrified mounted points. It provides longer life since the grains are getting cracked and break down at a much slower rate.

- Pink and White Aluminum Oxide. This form of aluminum oxide presents a starker contrast compared to brown aluminum oxide. It also breaks down in a much quicker phase.

2. Application of Aluminum Oxide Vitrified Mounted Points

Due to its durability feature, aluminum oxide vitrified mounted points are frequently used in various fields.

- Mainly used for internal and external bearing and grinding.

- It can be applied from general-purpose stock removal to light deburring. It is also used on the die in-line or straight shank grinders.

- Applied for medical implants and aerospace components

3. Features of Aluminum Oxide Vitrified Mounted Points

Here are some features of aluminum oxide vitrified mounted points that make them necessary and helpful in various fields of expertise.

- Very good shelf life and low cost in maintenance

- Highly proficient and very durable to use

- Wear resistance and provides longer service life

Industries or Markets where Vitrified Mounted Points are Applied

Whether it is aluminum oxide or silicon carbide vitrified mounted points, various industries make use of these tools for so many applications. Here are some industrial fields and areas that use Vitrified Mounted Points.

- Energy and Environment field

- Manufacturing and Industry

- Medical Industry

- Aerospace

- Automobile

- Metal Fabrication/ Welding

- Collision Repair

- Foundries

Selecting the Best Mounted Point Using Vitrified Mounted Points for your application

Getting the precise mounting points is crucial in achieving the best result you want for deburring and edge-breaking process. Here are five steps on how to select the best abrasive for your job.

- Choosing the Grain Type. Usually, aluminum oxide vitrified mounted points are used by workers. This is because it has versatile grain and is commonly paired with a specialty bond. It also grinds effectively with carbon steel, stainless steel, mild steel, aluminum, and alloys. When you apply this vitrified mounted point grain type, you can expect a high purity and brighter surface finish.

- Choose the Right Bond. To choose the perfect bond, remember that soft bonds work best for hard materials and hard bonds are applied on softer materials. In the application part, one instance is the removal of the edge on a stainless steel metal before fabrication.

- Choose the Grit Size. The grit size is very important since it will determine the amount of metal you need to remove. Always remember, the lower the grit level, the rougher the grain. If you like a faster stock removal, choose the rougher grit. If you prefer light deburring, edge breaking, or blending, choose a finer grit.

- Find the Accurate Shape. Shapes have a big factor in reaching burrs and sharp edges. Vitrified Mounted points come in various shapes such as A, B, and W which are applied in different applications.

- Verify the Maximum Operating Speed. Before using the vitrified mounted points, make sure your tool is not exceeding its maximum operating speed. This is very important for everyone’s safety and to avoid wearing out of the tool. If you operate at a higher speed, it might reduce the life of the point and may decrease the quality of the deburring job. You may refer to the speed chart included in the shipment for proper operating speeds.

Go through the steps and test it in actual processing. If you still don’t get the precise result you wanted, take note of the errors in the process. Remember the tips in grain types like choosing the finer grit for rough surface finish and harder bond for mounted points which removes too much metal. You can also try the VItrified CBN Mounted Points Wheel for internal grinding of Metal Steel. You may click here to view the product page.

Need more customized mounted points, feel free to contact us.

[wpforms id=”4612″]

Reviews

There are no reviews yet.