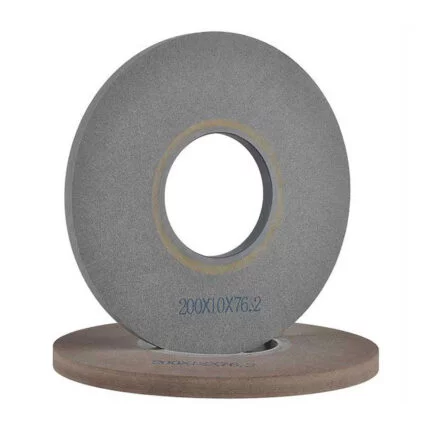

BD polishing wheel for glass

Short Description:

BD polishing wheel is the best polishing tool made of polymer materials and a very sharp combination of alumina and silicon carbide, which is produced by their reaction. These polishing wheels have better structure features when it comes to brightness and sharpness compared to the 10S polishing wheel. With its high molecular material, this polishing wheel is highly elastic has super wearability and high strength. BD polishing wheels are applied through common edge processing together with metal bond diamond wheel and resin bond diamond wheel.

Product Specification:

Here is a popular product specification for BD polishing wheels. Special parameters can be customized according to the client’s requirements.

| D (mm) | T (mm) | H (mm) customized |

| 100 | 22 | 15 |

| 100 | 22 | 20 |

| 100 | 22 | 25 |

| 100 | 22 | 30 |

| 150 | 22 | 15 |

| 150 | 22 | 20 |

| 150 | 22 | 25 |

| 150 | 22 | 30 |

| 150 | 22 | 35 |

| 200 | 22 | 15 |

| 200 | 22 | 20 |

Detailed Description of BD Polishing Wheel

Features of BD Polishing Wheel

BD polishing wheel has metal compounds that allow super cutting ability. Its elasticity feature allows the wheel in full contact. It also keeps the whole glass edge while polishing it thoroughly. This is the reason why the tool leaves no scraps in any glass due to its easy discharging and polishing. The elasticity feature reduces pressure which is a big factor in avoiding burns. Here are some of its benefits and features.

- Very sharp cutting and polishing features with its sharp combination of alumina and silicon carbide.

- It can maintain longer shape features.

- It has good elasticity, high polishing proficiency, and a good finish surface.

- Can be done for inner hole polishing.

- It has the remarkable function of eliminating scratches on glass.

- Has rigidity feature which prevents deformation or cracks even if there are glass edge defects, machine vibration, and improper operation.

- It also has an excellent bright satin finish due to its fine powder.

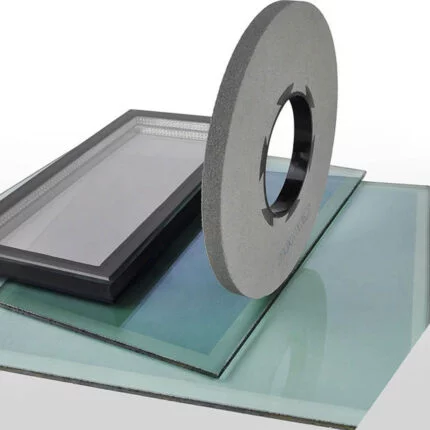

Application of BD Polishing Wheel

BD polishing wheel is the top-of-the-class polishing tool used for round glass tables, table glass, bathroom glass, water watch glass, and other types of glass products. It is also used for edging machines, double edging machines, beveling shapes for beveling machines, etc. BD polishing wheels are a good investment for glass fine polishing of furniture glass, decoration glass, and art glass.

Applicable Machine for BD Polishing Wheel

This polishing wheels are applied on profiled machines. Here are applicable machines that are partnered with the BD polishing wheel.

- CNC machining center and round edge machine

- Commonly used to match OG, 2OG, 3OG, 45

- Suitable for all the edging machine brands on the market such as Deway, ZXM, BOTTERO, BAVELLONI, bovone, Schiatti Angelo, etc.

- You can apply this using combination grinding wheels like internal diamond grinding wheel, continuous grinding wheel, resin diamond grinding wheel, and many more.

Tips on using BD Polishing Wheel

To maximize the use of the BD polishing wheel in the glass polishing process, take note of these tips and procedures on how to install and operate it.

- The first thing you have to do before doing any work process using your BD polishing wheel is thorough checks if the wheel is intact or not. Check if there are cracks visible or passivation.

- Next is to carefully install the wheel in the correct position and suitable machine. The process should be done according to the coarse polishing process, medium polishing, and fine polishing procedures.

- Use water in the grinding process especially when using a diamond grinding wheel. This is a very important factor in keeping the work efficient and can prolong the service life of the tool.

- Lastly, choose the correct and appropriate operation speed. This is very important in preventing damages to your polishing wheel and will secure safety on the part of the operator.

More Customized Polishing Wheels are available, contact us.

[wpforms id=”4612″]

Reviews

There are no reviews yet.