Grinding Wheel Dressing Sticks of aluminum oxide and silicon carbide are designed for shaping, truing, cleaning, and dressing the face on abrasive grinding wheels. They could effectively work on diamond wheels and conventional vitrified wheels. Silicon dressing sticks could help dress diamond wheels and conventional vitrified wheels and aluminum oxide dressing sticks can work perfectly on diamond profile wheels.

Features of Grinding Wheel Dressing Stick of Aluminum Oxide and Silicon Carbide

- Ensure maximum performance from grinding wheels

- Ideal for opening, cleaning, and reshaping grinding wheels

- Provide fantastic results when dressing conventional vitrified wheels

- Provide excellent results during rough finishing-stick work

- Crafted with a durable, sharp, and super-fine grit abrasives

Overview

Grinding wheels are expected to be given frequent dressing. In a situation whereby such is not duly observed, it could make the tools glazed over and lead to tearing instead of providing effective grinding. A tearing of tools can create friction and probably damage them as well as every work piece a handyman may be working on. Fortunately, with abrasive dressing sticks of aluminum oxide and silicon carbide, grinding wheels can be properly maintained by being kept sharp and efficient.

Detail Description

Abrasive dressing sticks of aluminum oxide and silicon carbide are designed to offer grinding wheels’ new life. Due to repetitive use, abrasive tools do wear down and experience change in shape. With abrasive dressing sticks, grinding and sharpening accessories can be adequately cleaned and reshaped, ensuring that they are kept sharp, flat, and running smoothly for the maximization of grinding performance.

With abrasive dressing sticks, handymen will find it easy to true, shape and dress grinding wheels and do the general dressing of super-abrasives and diamond wheels. One of the effective ways to getting the maximum life out of a wheel and improve its performance is to offer it a good dressing

There are aluminum oxide sticks and silicon carbide sticks. Each comes with its peculiar features. But, generally, dressing sticks are ideal for sharpening a variety of abrasive wheels.

Irrespective of the grit size of an aluminum oxide dressing stick, it can effectively work on diamond profile wheels. This explains why several handymen prefer using aluminum oxide sticks on diamond and CBN wheels. On the other hand, silicon carbide sticks are sharper when compared with aluminum oxide sticks. Silicon carbide dressing sticks are often recommended for coarse grits to effectively dress conventional vitrified wheels. It’s would be best if they are used in softer grades and fine grit sizes for good dressing of diamond wheels.

Common Uses of Grinding Wheel Dressing Stick for Diamond Grinding Wheel

Grinding wheel dressing sticks are preferred based on several reasons, relating to uses. Some of the common uses of abrasive dressing sticks of aluminum oxide and silicon carbide include:

- For reshaping and cleaning grinding wheels

- Offer new life to worn grinding wheel

- Expenses benefits as they ensure fantastic performance of grinding wheels

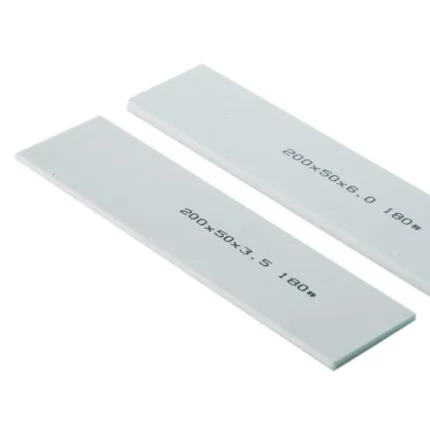

Specifications of Grinding Wheel Dressing Sticks of Aluminum Oxide and Silicon Carbide

Below are the various specs of Grinding wheel dressing sticks, featuring different lengths, widths, thicknesses, abrasives grain, grit, and shape.

| Size Range | Grit Range | Abrasive Grain | Shape | |

| Thickness/Width/Diameter | Length | |||

| 1/4″ – 1″ | 3″ – 8″ | 16 – 400 | · Aluminum Oxide

· Silicon Carbide |

· Square

· Rectangular · Round |

Summary

Grinding Wheel Dressing Sticks of aluminum oxide and silicon carbide are the proper solution when an abrasive tool appears glazed over, leading to tearing which is contrary to the job of grinding. Abrasive dressing sticks are designed to offer new life to your worn grinding wheel. So, be prepared to enjoy maximum performance from your grinding wheels when you make them your choice.

More customized Sharpening Stones are available, contact us.

[wpforms id=”4612″]

Reviews

There are no reviews yet.