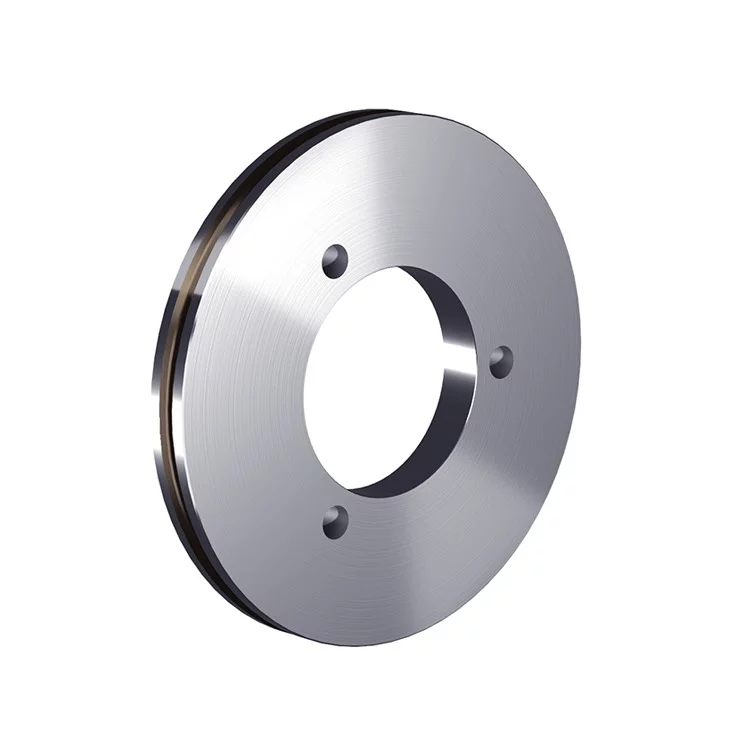

Diamond Automotive Glass Grinding Wheel

Short Description:

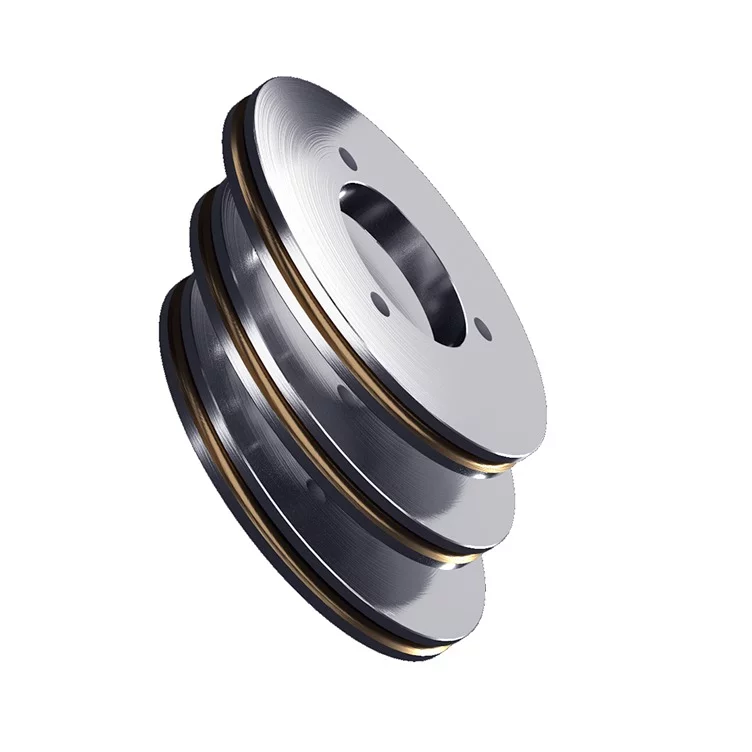

Diamond automotive glass grinding wheels are excellent tools for edge grinding on any automobile glass materials where its layer is an abrasive content that is suppressed to provide longer abrasion resistance and life indicator. This automotive glass grinding wheel has adopted patent technology which contributes a lot to upgrade the product accuracy by using finishing technology and three-dimensional spark. This tool is way more magnificent in its components and specifications.

Features of Diamond Automotive Glass Grinding Wheel

- Smooth and delicate surface finish. This product tool can guarantee a smooth and delicate finish on any auto glass edge after the grinding process. It also has the highest edge quality requirements in automotive glass.

- Durability and Firmness: With its high-tech touch, you can expect a longer service life since its composite technology improves the sintering performance of the metal binder and control the tool strength. This provides a 30% longer service life and firmness on average.

- Cost-effective and high work efficiency: The durability feature makes the tool perform on its utmost work efficiency level and will prevent unexpected costs and expenses, especially on the maintenance components.

- High-quality material. You can expect a high grinding performance with this super abrasive material. Its newly developed wheels help in improving the edge quality of the surface material and reduce chips (less than 1% deviation of the chipping rate after refurbish).

- Best operational mechanisms. Unlike other automotive glass grinding wheels, this tool has a short running-in period and a high pass rate on specific online products.

Detailed Description of Diamond Automotive Glass Grinding Wheel

When it comes to grinding automotive safety glass, this automotive glass grinding wheel is the most preferred tool to use because of its magnificent product specifications, applications, and benefits.

Product Specification:

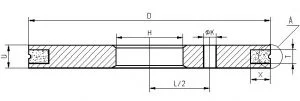

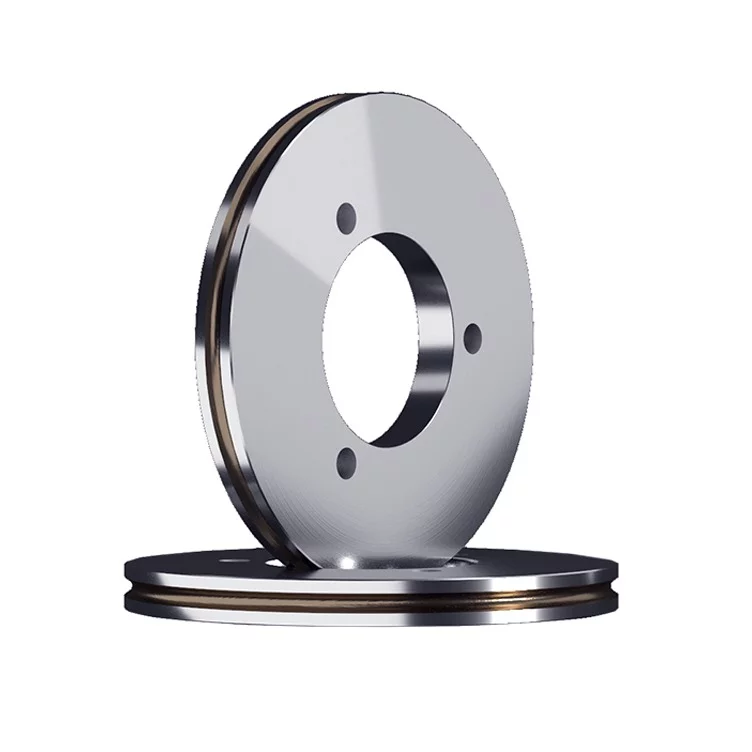

Here’s a popular product specification you can use when purchasing this awesome grinding tool. There is also an available specification for the grinding case of auto glass. Customization of the sizes and shapes can be done according to the client’s needs and requirements.

| Name | Specification (mm) | Granularity | |||

| D | H | X | T | ||

| Diamond

Automotive Glass Grinding Wheel |

100

120 150 204 247 250

|

22

30 45 50 63.5 75 191.3

|

5

7 10

|

10

12 15 16 20

|

120#

150# 200# 240#

|

Grinding Case for Auto glass:

| Grinding Wheel | GOA formula |

| Linear Velocity | 45 m/s |

| Machine | Bystronic edge grinding machine |

| Workpieces | UV green glass 3.5 mm |

| Grinding margin | 0.3 – 0.5 mm |

| Grinding velocity | 14 – 16 m/min |

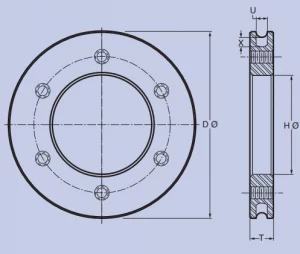

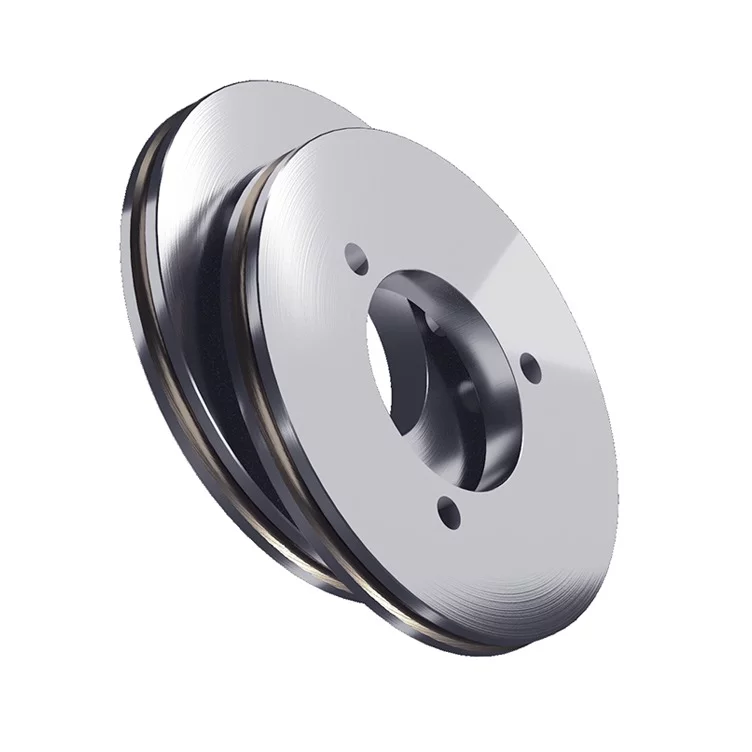

Four Essential Parts:

This diamond tool for automotive glass processing has four essential parts that composed its diamond-bond specification. These are the mesh, diamond-type, concentration, and bond. Every type has a great effect on the performance of the automotive glass grinding wheel which may depend on the application.

- Mesh. The mesh talks about the size of the diamond materials. The mesh of this automotive glass grinding wheel is determined by the size of the screen where it is being strained. The screen’s number of holes per inch square reflects its size. The mesh is actually between two screen sizes.

Note: The lower the mesh of the diamond (i.e., from 150 to 180), the higher the number of diamond particles per carat.

| Screen size | Applications |

| 80 / 100 | Drilling |

| 100 / 120 | Drilling |

| 120 / 140 | Drilling, Chamfering |

| 140 / 170 | Pencil Edging |

| 170 / 200 | Pencil Edging, Seaming |

| 200 / 230 | Pencil Edging, Seaming |

| 230 / 270 | Seaming |

| 270 / 325 | Seaming |

- Diamond Type. This concerns the quality of the diamond. The quality will depend on the application of the material where you can utilize either a synthetic or natural diamond. This automotive glass grinding wheel has high-quality diamonds characterized by its toughness, shape, and friability index.

- Concentration. This part identifies the quantity of the diamond particles. A standard measurement (carats per cubic inch) is used to measure the quantity or concentration of diamonds. For instance, a 100 concentration is equal to 25% by volume diamond, which is equal to 72 carats per cubic inch (4.4 carats per cubic inch centimeters).

- Bond. The bonds are very important since it has a great impact on the application part of the tool. This is considered the key ingredient in the performance of the automotive glass grinding wheel. The bond can be composed of a matrix of metals where the diamond is being dispersed. The bond matrix provides better wear-resistant which is highly applicable and helpful on various glass grinding works.

Applications of Diamond Automotive Glass Grinding Wheel

With the new inventions on automotive glass, grinding wheels have become popular and resulted in more complex and stringent guidelines, especially for shaping which involves cutting and grinding, and processing which includes tempering, lamination, bending, and add-ons. Here’s detailed data about the application of the diamond automotive glass grinding wheel.

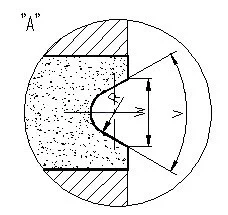

- This grinding wheel can be applied for coarse and precise grinding of T-Shape edge, arc edge, V-shape edge, and L-shape edge of front and back windshield, side, corner, and skylight windows on various automotive glasses.

- This tool is mainly used for automobile glass edge grinding devices such as hand edge grinders, shape grinders, profiling grinders, and CNC automatic edge grinders.

- It is also applied for edge grinding on side mirrors, glass hole grinding, and home appliance glass.

- This abrasive tool has specific applications on specific bonds such as seaming, pencil edging, drilling, chamfering, and many more.

- It can be a great device for the edge grinding process on windshields, side windows, backlights, and sunroofs.

Cutting and Operating Parameters of Diamond Automotive Glass Grinding Wheel

The cutting parameters have a great contribution to the performance of this diamond grinding wheel which has a direct relationship to the removal rate of the material. There are three (3) major cutting parameters: RPM, grinding speed, and depth of cut.

- RPM. For glass processing and grinding applications, an RPM of 40 to 60 m/s is the recommended ideal peripheral speed. Note in mind that the larger the diameter of the wheel, the higher the recommended peripheral speed or RPM.

- Grinding Speed. The removal rate on the material and the kind of application will play a big part in it. The lower the removal rate on the material, the faster the grinding speed that the wheel can perform to achieve that ideal predetermined surface finish. But the grinding speed also has an effect on the quality of the surface finish and the service life of the tool. The higher the grinding speed of the wheel, the lower the quality of the surface finish and service life.

- Depth of cut. The application process and operator’s requirement will be the basis of the depth of cut of this grinding wheel. For an instance, a 20% – 30% depth can be done for seaming windshield and backlight.

This automotive glass grinding wheel has a lot of advantages when it comes to automotive glass processing. Various industries are turning to this super abrasive diamond tool because of its high-quality components and design which offers greater value compared to a standard profiled wheel. Plus, this grinding wheel is available for various customization that the customer needs.

More customized grinding wheels are available, contact us.

[wpforms id=”4612″]

Reviews

There are no reviews yet.