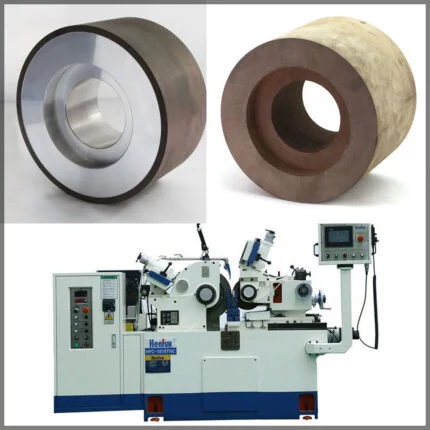

Half Segmented Diamond Wheel for Optimal Glass Edging:

Half segmented diamond wheel is widely used for the processing of beveled glass, after rough grinding of full segmented diamond cup grinding wheel. It is suitable for medium rough grinding of glass. A half-segmented diamond wheel is a metal bond diamond grinding wheel created using sintered technology, which involves fusing diamond and copper powder at high pressure and temperature. The diamond utilized is of excellent grade, ideal for glass production. High sharpness, high strength, no chipping, and heat or thermal endurance are all properties of a half-segmented diamond wheel for glass edging.

Features of Half Segmented Diamond Wheel :

- a high efficiency, high engagement, and rapid removal of uneven glass edges

- a good sharpness, and no chipping of the grinding glass

- After processing, the products have a good brilliance, the glass edge is smooth, and there are no lines.

- a long service life, as well as a reduction in the time it takes to replace the wheels.

- Wheel life is extended.

- Dressing frequency is reduced.

- Form retention is exceptional.

- A superior surface finishes

- Enhanced efficiency

- Future-oriented

- With a solid link and less damage, you may expect a longer lifetime.

Detailed Description of Half Segmented Diamond Wheel:

Types of Half Segmented Diamond Wheel:

-

Inner Segmented Diamond Wheel:

An inner half segmented diamond wheel is a cup-type wheel that has great grinding efficiency. It has sharp edges on its inner side. It has less heat output and is has optimized self-sharpening ability Diamond wheel associated with resin bond is also available and this bond further improves its working capability. It is widely used for the processing of beveled glass.

Features:

- Inner sharp segments

- Excellent choice for bevelled glass

- Self-Sharpening

- A superior surface finishes

- No Surface Damage.

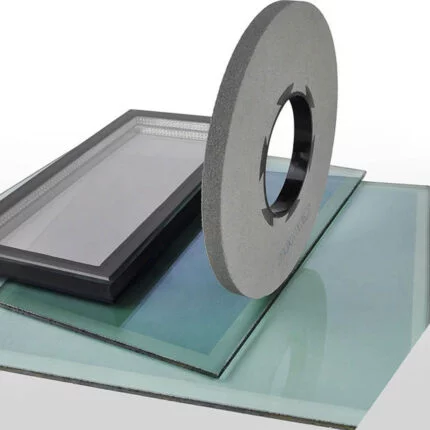

Applications of Inner Half Segmented Diamond Wheel:

These diamond wheels are great for straight line and bevelling machines. These wheels are best suited for glass, safety glass, tempered glass, optical glass, solar glass, and auto glass edging.

2. External Half Segmented Diamond Wheel:

External half segmented grinding wheels are also cup-type wheels having external sharp segments for optimal glass edging. Both types of wheels are used for glass edging. Selecting the suitable wheel depends on if you are using it for internal edging or external edging. These wheels are also available in resin bond as well as in metal bond. This further improves efficiency. wheel with the desired bond is selected based on the surface nature of grinding glass.

Features:

- Optimized for internal grinding

- Excellent for final finishing

- No heat generation.

- Superior surface finish

- Dressing frequency is reduced.

6. Form retention is exceptional

Application:

External half segmented grinding wheel is suitable for internal edging between two surfaces. It is suited to optical glass, solar glass, tempered glass, and all other types of glass for its edging and optimized surface finishing.

Guidelines For Perfect Usage of Half Segmented Diamond Wheel:

High efficiency, high engagement, and the ability to swiftly remove the glass with uneven edges. It Provides Excellent sharpness, with no chipping of the grinding glass. The goods have a nice brilliance, the glass edges are smooth, and there are no lines after processing. Long service life, as well as a reduction in the number of times the wheels need to be changed over time.

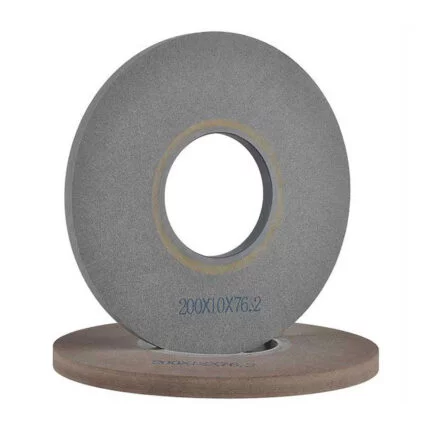

- Diamond abrasive wheels are split into three types: complete segmented, half segmented, and full-rim; please choose the specification and grit based on the scenario.

- The goods are suitable for glass thicknesses ranging from 3 to 25 mm, and the machines’ pressure and transport speed are adjusted following the thickness of the glass.

- Adjust the location and angle between the abrasive wheel and the glass according to the size of the glass.

- Compress pieces to keep them in place, ensuring a straight trajectory for the glass, and keep it from sliding and jittering.

Summary :

Half segmented diamond wheel is widely used for the processing of beveled glass, after rough grinding of full segmented diamond cup grinding wheel. Both inner and external half-segmented wheels are available. You can choose the wheel according to the nature of your work. Each type has it’s unique features. Our products are employed in a broad range of glass edging machines, including vertical and horizontal single, double, form, and beveling machines, as well as imported and local glass edging machines. We can also customize wheels for you. You can order products of desired specifications and usage.

More customized grinding wheels are available, contact us.

[wpforms id=”4612″]

Reviews

There are no reviews yet.