Grinding wheels feature abrasive grains and fiberglass layers, which are bonded into a wheel shape using another substance. Abrasive grains are, basically, grinding tools that help remove material from a work piece with the aim of giving it a smooth, accurate, and refined surface. But as one of the numerous abrasive tools used in several industries for different crucial operations, these wheels have their own service life. So, what is the service life of the grinding wheel?

Abrasive Tools and Their Service Life

The service life of abrasive tools refers to the time period over which tools are expected to be used until replacements are needed on account of signs of wear. There are common indicators that determine how long abrasive tools can last. These include the number of times the tools are used for cutting and the number of work pieces processed using the same tools. Other factors that could influence the service life of abrasive tools related to their manufacturing processes include the volume, type, and quantity of the abrasive grain and the composition and structure of the bond (hardness, type, and filler materials).

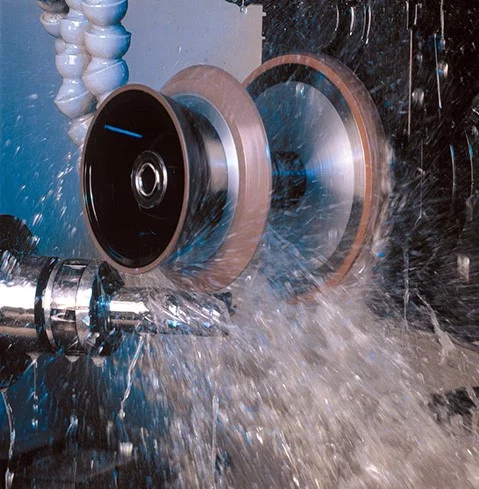

A grinding wheel as a super abrasive tool is used in several operations that involve grinding and machining. Its composition of small abrasive grains, which serve as the cutting tools, are designed to give a work piece a great shape. Nonetheless, as the grains become dull, they detach from the bonding material. But the important question to ask is what is the service life of the grinding wheel?

To calculate how long a grinding wheel can last, the usable abrasive will be divided by wheel wear. It should be noted that the amount of dressing is programmed per the wheel's revolution. What determines the number of revolutions a grinding wheel completes in a single cycle includes the wheel speed in sfpm, wheel diameter, the depth of cut, the grinding length, and the table speed

The Service Life Of The Grinding Wheel: Do Grinding Wheels Expire?

As several cutting tools experience wear and tear over time, grinding wheels are not an exception in any way. They are prone to wear and tear, resulting in rough and inaccurate surface finishes and poor part quality. But why do grinding wheels expire? Some of the factors that could cause degradation in the bonding agents of abrasive wheels after being used over time include humidity, UV light, and temperature fluctuations.

The Service Life Of The Grinding Wheel: How Long Does a Grinding Wheel Last?

Since grinding wheels can be classified into different types, the expiration dates may depend on each type. This implies that each of the different types might feature different expiration times. Good examples include bench abrasive wheels, resinoid grinding wheels, and CBN grinding wheels.

What is the service life of the grinding wheel? Those who prefer bench grinder abrasive wheels may enjoy their service for about two years. Their expiration time depends on storage conditions for resin-bonded grinding wheels. If properly stored, the wheels can be fit for use with excellent strength for more than two years.

Industries that select CBN wheels as their grinding tools can use them for a more extended period (300 times compared to other wheels) if proper attention is given to workload and care. Although CBN grinding wheels might end up wearing down over years of use, they can continue to grind if they are well-cared for.

The Service Life of the Grinding Wheel: Reasons for the Degradation of Grinding Wheels

Grinding wheels have a special place in several industries that use grinding tools. And this is why their life is given more attention. Nonetheless, the service life of the grinding wheel can be affected by wear and tear. So what could affect the extended service life of the grinding wheel?

- Excessive Heat Generation: Grinding wheels are produced using abrasive and bonding agents. Due to how it's inevitable for the work piece and the wheel to generate heat during the grinding process, the bonding agent will end up softened easily.

- The contact between the Cutting Tools and the Surface Particles: After using grinding wheels for an extended period with much effort, they become a bit blunt. This is primarily because of the contact between the cutting tools and the surface particles during work, which leads to gradual wear of the wheel as the grinding resistance goes beyond the adhesion between the bonding agent and the particles. The particles wear off gradually, and new sharp particles replace them.

- The Bonding Agent Fails to Bond the Particles: The bonding agent and the ground metal material are bonded and positioned rightly between the sand grains to ensure that the wheel is filled. Continuous use of this plug-in grinding wheel will reduce the efficiency of the work and turn the sharpened cutting tool to blue, leading to annealing.

However, if the bonding agent is unable to bond the particles, there is a tendency that the wheel will wear off when the particles are not purified. And the sand transmission line will wear off quickly and become deformed, requiring frequent trimming.

The Service Life of the Grinding Wheel: the Key to the Longevity of the Grinding Wheel

There are several key factors grinding tool operators must pay special attention to. These factors will make their wheels last as long as they want, particularly when purchased mainly for sharpening and honing work pieces.

What should you do to ensure that your grinding wheels last longer?

- You should make sure that you give them a good cleaning at least once in a while using WD-40 or Kroil lubricant.

- You should ensure that the grinding wheels are off and then give the surface a good scrub using a toothbrush or steel brush.

Note: As much as you pay proper attention to caring for the grinding wheel and not using them inappropriately, you can be guaranteed that your wheels will remain sharp for a lifetime.

To know more about various grinding wheels, visit our website at agrindtool.com. You can also check our post on grinding wheel selection guide for ideal instructions.

Conclusion

The Importance of grinding wheels cannot be underestimated in several industries. And this explains why it's crucial to keep them in good condition. Nevertheless, like other cutting tools, the service life of the grinding Wheel usually depend on the type and how they are used and stored. For grinding wheel operators, you should ensure that they are cared for properly for their service life can be impressively extended.